Британская самоцентрируящаяся комбинированная прокладка из оцинкованной углеродистой стали

- Категория: >>>

- Поставщик: Tianjin Relly Technology Co. Ltd.

Сохранить в закладки 1601246328229:

Описание и отзывы

Характеристики

Tianjin Relly

OEM & ODM

A wide variety -- Fast shipping -- Precise dimensions -- Customization available

Over 6000 types of O-rings in stock

Plenty of inventory, buy now and we’ll ship right away

15+ years of production/manufacturing/export experience

Contact us now for great discounts

Product parameters

1. They use strict manufacturing standards to ensure the precision of size and tolerances. This level of accuracy is crucial for preventing leaks, especially in high-pressure or high-temperature environments where a tight fit between the gasket and the contact surface is essential to minimize medium leakage.

2. Depending on the application needs, English-style composite gaskets can be made from various specialized materials like PTFE, silicone, and metal composites. These materials offer great resistance to heat, pressure, and corrosion, making them capable of handling complex working environments while ensuring long-lasting sealing performance.

2. Depending on the application needs, English-style composite gaskets can be made from various specialized materials like PTFE, silicone, and metal composites. These materials offer great resistance to heat, pressure, and corrosion, making them capable of handling complex working environments while ensuring long-lasting sealing performance.

We will provide you with comprehensive customization

Product Name | Compound gasket |

Application | Industry, motorcycle, automobile, machines,truck, tractors, valves, etc. |

Material | NBR, FKM, SILICONE, EPDM,SBR,SR,CR, HNBR,etc. |

NBR:-40-+125 °C high tensile, poor weather, etc | |

FKM:-20-+250 °C excellent weather, limited tensile,etc | |

VMQ:-60-+225 °C excellent weather, poor tensile |

Size | ID/mm | OD/mm | H/mm | B/mm | A/mm |

M4 | 4.5 | 7 | 1 | 5.4 | 3.3 |

M5 | 5.7 | 10 | 1 | 7.4 | 4.45 |

M6 | 6.7 | 10 | 1 | 8 | 5.6 |

M8 | 8.7 | 14 | 1 | 10.4 | 6.4 |

M10 | 10.7 | 16 | 1.5 | 12.4 | 8.05 |

M12 | 12.7 | 19 | 1.5 | 14.1 | 9.73 |

M14 | 14.7 | 22 | 1.5 | 16.4 | 11.38 |

M16 | 16.7 | 24 | 1.5 | 18.4 | 13.41 |

M18 | 18.7 | 26 | 1.5 | 20.4 | 14.76 |

M20 | 20.7 | 28 | 1.5 | 22.5 | 16.76 |

M22 | 22.7 | 30 | 2 | 24.4 | 18.74 |

M24 | 24.7 | 32 | 2 | 26.4 | 20.11 |

M26 | 26.7 | 35 | 2 | 22.3 | |

M27 | 27.2 | 36 | 2 | 23.3 | |

M30 | 31 | 39 | 2 | 25.7 | |

M33 | 33.7 | 42 | 2 | 28.7 | |

M36 | 36.7 | 46 | 2 | 31.1 |

Product display

What benefits can we bring to you???

*We can customize various shapes, sizes, and hardness levels of rubber seals, tire sealing rings, gear pump sealing rings, injection molding machine sealing rings, pressure pipeline sealing rings, etc., based on the drawings or samples provided by our clients.

*We have advanced processing equipment and reliable manufacturing techniques that can meet all kinds of customized needs for special-shaped rubber seals.

*During production, we strictly control the selection of raw materials, product quality testing, and after-sales service to ensure that every batch of products meets our clients' requirements.

*We actively promote an innovative, high-quality, and efficient work philosophy to provide our clients with satisfactory service.

*We can customize various shapes, sizes, and hardness levels of rubber seals, tire sealing rings, gear pump sealing rings, injection molding machine sealing rings, pressure pipeline sealing rings, etc., based on the drawings or samples provided by our clients.

*We have advanced processing equipment and reliable manufacturing techniques that can meet all kinds of customized needs for special-shaped rubber seals.

*During production, we strictly control the selection of raw materials, product quality testing, and after-sales service to ensure that every batch of products meets our clients' requirements.

*We actively promote an innovative, high-quality, and efficient work philosophy to provide our clients with satisfactory service.

Product advantages

Half-pack combined gaskets

Temperature range: -40°C to 120°C

Hardness: Typically measured in Shore A or Shore D, with common hardness ranging from 30A to 90A.

Colors: Commonly available in black, gray, white, blue, green, etc.

Advantages:

1. Good sealing properties: Effectively prevents leaks of liquids and gases, enhancing equipment efficiency.

2. Shock absorption: Capable of absorbing vibrations, reducing mechanical noise, and protecting equipment.

3. Chemical resistance: Certain materials have good chemical resistance, making them suitable for harsh environments.

4. Strong adaptability: Can be customized for various applications to meet specific size and performance requirements.

Temperature range: -40°C to 120°C

Hardness: Typically measured in Shore A or Shore D, with common hardness ranging from 30A to 90A.

Colors: Commonly available in black, gray, white, blue, green, etc.

Advantages:

1. Good sealing properties: Effectively prevents leaks of liquids and gases, enhancing equipment efficiency.

2. Shock absorption: Capable of absorbing vibrations, reducing mechanical noise, and protecting equipment.

3. Chemical resistance: Certain materials have good chemical resistance, making them suitable for harsh environments.

4. Strong adaptability: Can be customized for various applications to meet specific size and performance requirements.

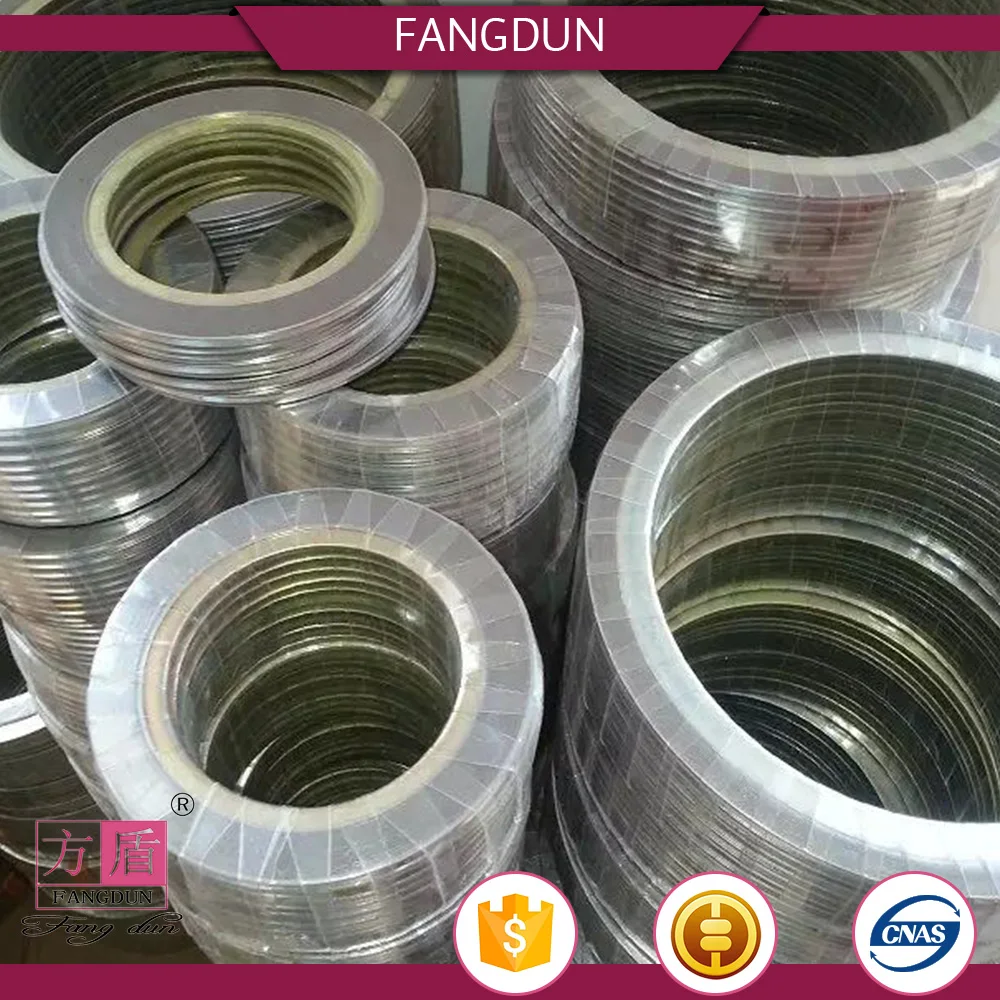

Imperial combined gaskets

Temperature range:

-20°F to 250°F (approximately -29°C to 121°C), with special materials (like PTFE or high-temperature silicone) able to withstand even higher temperatures, usually up to 450°F (about 232°C).

Hardness: 30A to 90A (using Shore A or Shore D standards)

Colors: Black, white, red, blue, green, etc.

Advantages:

1. Effectively prevents leaks of liquids and gases, improving equipment operational efficiency.

2. Allows selection of suitable materials based on different working conditions, meeting various industrial needs.

3. Some materials exhibit strong resistance to various chemicals, suitable for extreme environment applications.

4. Helps reduce operational noise and vibration, protecting both equipment and operators.

5. Typically designed for reuse and easy replacement, minimizing downtime.

Temperature range:

-20°F to 250°F (approximately -29°C to 121°C), with special materials (like PTFE or high-temperature silicone) able to withstand even higher temperatures, usually up to 450°F (about 232°C).

Hardness: 30A to 90A (using Shore A or Shore D standards)

Colors: Black, white, red, blue, green, etc.

Advantages:

1. Effectively prevents leaks of liquids and gases, improving equipment operational efficiency.

2. Allows selection of suitable materials based on different working conditions, meeting various industrial needs.

3. Some materials exhibit strong resistance to various chemicals, suitable for extreme environment applications.

4. Helps reduce operational noise and vibration, protecting both equipment and operators.

5. Typically designed for reuse and easy replacement, minimizing downtime.

Fluoroelastomer combined gaskets

Temperature range:

Works within -20°C to 200°C (-4°F to 392°F), with some high-performance fluoroelastomer materials rated for higher temperatures, up to 260°C (500°F).

Hardness: 60A to 90A

Colors: Fluoroelastomer combined gaskets are usually black, green, red, or brown.

Advantages:

1. Fluoroelastomer shows excellent resistance to a variety of chemicals (like oils, solvents, and acids), making it ideal for harsh industrial environments.

2. Suitable for high-temperature applications, retaining shape and elasticity without distortion.

3. Exceptional aging resistance, effectively prolonging lifespan.

4. Maintains good performance under extreme temperatures and humidity, resisting slackening or failure.

5. Effectively prevents fluid leaks, improving overall equipment efficiency.

Temperature range:

Works within -20°C to 200°C (-4°F to 392°F), with some high-performance fluoroelastomer materials rated for higher temperatures, up to 260°C (500°F).

Hardness: 60A to 90A

Colors: Fluoroelastomer combined gaskets are usually black, green, red, or brown.

Advantages:

1. Fluoroelastomer shows excellent resistance to a variety of chemicals (like oils, solvents, and acids), making it ideal for harsh industrial environments.

2. Suitable for high-temperature applications, retaining shape and elasticity without distortion.

3. Exceptional aging resistance, effectively prolonging lifespan.

4. Maintains good performance under extreme temperatures and humidity, resisting slackening or failure.

5. Effectively prevents fluid leaks, improving overall equipment efficiency.

Technological process

Product packaging

Company profile

Tianjin jerry lin technology & development co., ltd is a company specializing in the design, development, and manufacturing of rubber products, with a history of twelve years. We now have modern facilities for manufacturing o-rings, custom molded elastic seals, radial shaft seals, oil seals, hydraulic seals, pu piston and rod seals, non-standard rubber seals, rubber to metal bonding components, reinforced fabric seals, and rubber shock absorbers.

We have implemented a quality and management system that meets the strictest standards. We conduct tests on each batch of materials to verify compliance.

Each molding machine is controlled by a computer to ensure consistency and optimize productivity.

We have implemented a quality and management system that meets the strictest standards. We conduct tests on each batch of materials to verify compliance.

Each molding machine is controlled by a computer to ensure consistency and optimize productivity.

Our factory

Our mission is to continuously improve our products and services to meet or exceed customers' sealing needs.

FAQ

Q. What is your standard packing?

A: All the goods will be packed by carton box and loaded with pallets. Special packing methods can be accepted when needed.

Q. What is the normal lead time for product orders?

A: Generally it is 1-2 days if the goods are in stock. or it is 5-10 days if the goods are not in stock, it is according to quantity.

Q: Do you use any international standards for rubber products?

A: Yes, we mainly use ASTM D2000 standard to define the quality of the rubber materials, and tolerances as per ISO3302, ISO2768, etc.

Q: What materials are available to produce from your side?

A: NBR, EPDM, SILICONE, FPM(FKM), NEOPRENE(CR), NR, IIR, SBR, ACM, AEM, Fluorosilicone(FVMQ), FFKM, Liquid Silicone, Sponge, etc.

Q: Could you please tell us the month capacity of your products?

A: It depends on which model, we produce more than 2500 tons of rubber materials per month.

A: All the goods will be packed by carton box and loaded with pallets. Special packing methods can be accepted when needed.

Q. What is the normal lead time for product orders?

A: Generally it is 1-2 days if the goods are in stock. or it is 5-10 days if the goods are not in stock, it is according to quantity.

Q: Do you use any international standards for rubber products?

A: Yes, we mainly use ASTM D2000 standard to define the quality of the rubber materials, and tolerances as per ISO3302, ISO2768, etc.

Q: What materials are available to produce from your side?

A: NBR, EPDM, SILICONE, FPM(FKM), NEOPRENE(CR), NR, IIR, SBR, ACM, AEM, Fluorosilicone(FVMQ), FFKM, Liquid Silicone, Sponge, etc.

Q: Could you please tell us the month capacity of your products?

A: It depends on which model, we produce more than 2500 tons of rubber materials per month.

Похожие товары

Преимущество по цене EPDM + PTFE прокладка составная труба с фтором химическая Фланцевая национальный стандарт

88,17 ₽ - 110,22 ₽

Прочный уплотнительный кольцевой уплотнитель PPL для электронных устройств

55,11 ₽ - 109,11 ₽

Композитный не асбестовый графитовый лист прокладки высокопрочный Соединительный

214,92 ₽ - 281,04 ₽

Гарантия на продукт ptfe спиральная прокладка с сертификатом

Индивидуальные спецификации черные насосные фланцевые прокладки заполненные ПТФЭ уплотнения модифицированные графитовые

22,05 ₽ - 1 102,12 ₽

Модифицированная прокладка из ПТФЭ высокотемпературная графитовая спиральная Герметичная с фланцем для обмотки

22,05 ₽ - 1 102,12 ₽

Лидер продаж черная прокладка из ПТФЭ Графитовая

22,05 ₽ - 1 102,12 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $