QT8 15 автоматический полый блок машина гидравлический делая машину

- Категория: >>>

- Поставщик: Linyi Youju Machinery Co. Ltd.

Сохранить в закладки 1601246818609:

Описание и отзывы

Характеристики

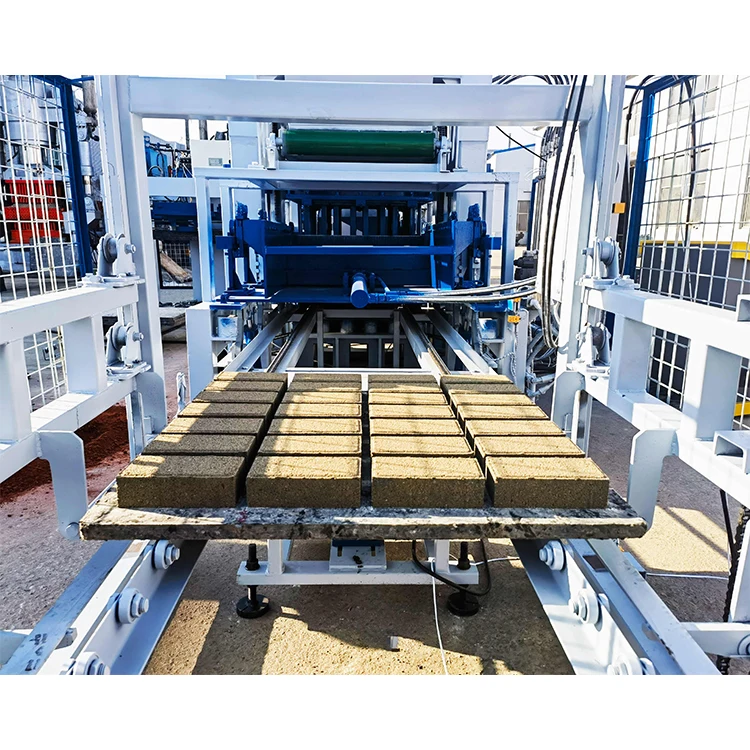

paving slabs interlocking block making machine

brief introduce about QT8-15 paving slabs interlocking block making machine

1. Super-strong steel structure made of extensive imported original parts, ensuring more stability and reliability for the concrete block machine body.

2. The whole process uses a PLC aptitude control and dialogue system of human-machine interface, easy to analyze the chance signal, ensure the best operation effect.

3. High-efficient and super-strong vibration system, computer-control flow pressure of the hydraulic system, realize vertically synchronous vibration, frequency conversion, and braking, with synthetic output compounded with double vibration sources, thus greatly increase product compactness and mould-box service life.

4. The cloth system adopts semi-closed screen reticular rotational feeding unit to feed materials forcedly, with evenness and even speed, ensuring product intensity.

5.Fitted with special hydraulic loading unit, readily realize mass and automatic production, saving a great deal of human power, maintenance field, and circulating fund investment

main parameters about QT8-15 cement hollow block making machine

Technical Parameters of QT8-15 Automatic paver block interlock paving brick making machinery production line price | |

Overall Dimension | 8300*1860*3000mm |

Rated Pressure | 21MPa |

Main Vibration Form | Platform Vibration |

Vibration Frequency | 2800~4500 ( r/min) |

Pallet Size | 950*900mm |

Molding cycle | 15-25 (s) |

Overall Power | 55.5KW |

Vibration Force | 60KN |

Total Mass | 9T |

Demolding method | Hydraulic |

General water consumption | 12T/Day |

Factory Area | 600m2 |

Applied Products | Concrete blocks, hollow/solid blocks, pavers, interlocking blocks , curbstone, colored pavers ,etc. |

Raw Material | Crushed stone, sand , cement, dust, and fly ash, gravel, slag, and other raw material , etc. |

productivity and common bricks sample

advantage

1.Short molding cycle,high productivity,

2.Stable and reliable performance,can endure long-term fatigue-resistant use.

3.Can add block raw materials automatically and the blocks can be stacked Immediately.

4.Can produce both solid blocks and hollow blocks; and can produce paver blocks / curb stones with a plus-material-feeder Machine.

5.Type characteristic: Completely automatic block making machine

6.Productivity: 20% higher productivity than the similar products

7.Technical superiority: Adopt the most advanced computer-controlled technology

8.Functional performance: Can be used to make various blocks & bricks in dimension,shape and use,and various block raw materials are applicable

our fighting team

Inquiry service:

Accept user’s enquiries by all kinds of ways and establish user’s product cognition.Provide all kinds of product data and let customer understand characteristics of product.

Pre-sale service:

Accept inquiry of customers ,confirmation of investment advice of choice of product ,assist the customers to design the workshop

In-sale service:

Sale of product,help customers build the base ,technical training of customers’ workers ,practice of operation ,help to install ,train the operators in the workshop.

After-sale service:

24 hours service of technology inquiry, instant components supply, regularly technical service guidance of maintain,long distance malfunction control.

Unique service:

System upgrade,special design according to the customers’ requirement, mould renew ,supply new technology and products information.

Promise

1.Welcome to our website,you will find your best like styles!

2.Wanna you see,just wanna you do now!

3.Your satisfaction is necessary to our success.

4.Our goal is to provide you with the best level of customer service, and we welcome your comments and suggestions.

Welcome your consultation

Похожие товары

Shunya Высокоэффективная машина для производства QT4-30 блоков строительных

Лучшая цена Qt3-15 автоматическая гидравлическая блочная машина

Высокое качество QT4-30 автоматический блок делая машину для продажи высокое

Прочный блочный станок с отличной прочностью для долговременного производства блоков в тяжелых конструкциях

Qt4-15 гидравлический блок делая машину полые блоки машина изменение формы кирпич

Автоматический блок машина автоматический полый QT6-15

Гидравлический блок делая машину цена полностью автоматический цилиндр бетона кирпича оборудование

Новые поступления

Новинки товаров от производителей по оптовым ценам