Индивидуальное литье под давлением высококачественные пластиковые ABS/нейлон/PC/PMMA Запчасти для оборудования

- Категория: >>>

- Поставщик: Shandong Chengshuo Metal Products Co. Ltd.Shandong Ltd.

Сохранить в закладки 1601249197540:

Описание и отзывы

Характеристики

Products Description

Material | Description | Benefits | Applications |

ABS | Common thermoplastic with good impact resistance and toughness. | 1.Good impact resistance with toughness and rigidity 2.Metal coatings have excellent adhesion to ABS 3.Excellent processability and appearance | 1.Computer housings 2.Musical instruments(recorders & plastic clarinets) 3.Telecom devices 4.Small appliances(enclosures) 5.Automotive (interior trim, wheel covers,emblems) 6.Medical components |

Polypropylene | Thermoplastic polymer used for a wide number of applications. | 1.Excellent moisture resistance 2.Food grades available 3.Mold-in hinge possible 4.Good impact strength | 1.Packaging 2.Industrial components for fluid processing 3.Household goods 4.Automotive 5.Electrical hardware |

Polyoxymethylene (POM) | Dimensionally stable thermoplastic with high stiffness and low friction. | 1.High tensile strength with rigidity and toughness 2.Good impact and solvent resistance 3.Glossy molded surface 4.Low static and dynamic coefficients of friction (slippery) 5.Many grades have FDA and NSF approvals on food and water contact 6. Replace die-cast metal components | 1.Mechanical automotive 2.Business machines 3.Household appliance 4.Gears 5.Bushings 6.Door handles 7.Seat belt parts |

Polycarbonate | Thermoplastic material with good temperature resistance and impact strength. | 1.High impact resistance 2.Clarity 3.Dimensional stability 4.Chemical resistance(PC blends) | 1.Automotive headlights 2.Business machines 3.Consumer products 4.Telecommunications 5.Medical products 6.Mechanical goods |

Polycarbonate /ABS | Blend of PC and ABS that creates strong parts for a variety of applications. | 1.Good impact resistance with toughness and rigidity 2.Metal coatings have excellent adhesion to ABS 3.Very good indoor UV light color stability 4.Excellent processability and appearance | 1.Automotive exterior and interior components 2.Medical hardware 3.Electrical housings 4.Computers 5.Monitors 6.Business equipment housings 7.Enclosures |

PVC | PVC is a polymer with good insulation properties, high hardness, and good mechanical properties. | 1.Wide range of flexibility 2.Flame retardant 3.Dimensional stability 4.Low cost | 1.Medical/healthcare products 2.Automotive applications 3.Household items 4.Electronic extruded wire covering |

Nylon | Polymer material that is durable with high elongation and good abrasion resistance. | 1.Temperature capability 600--700 for short term 2.Excellent chemical resistance 3.High resistance to abrasion 4.Tough and withstands repeated impact | 1.Automotive components 2.Bearings 3.Electronic connectors 4.Gears 5.Consumer products 6.industrial products |

Nylon 32%Glass Fiber | Polymer with excellent mechanical stiffness and elevated temperature resistance | - | - |

Acrylic (PMMA) | Material with resistance to breakage often used for transparent applications | 1.Excellent optical clarity 2.Excellent weatherability and resistance to sunlight 3.Rigid with good impact resistance 4.Good light transmission | 1.Automotive transparent items such as head/tail lenses and trim 2. Household light fixtures and decorative items 3.Safety equipment and shields |

Polystyrene | Light weight material popular for its high impact strength and toughness. | 1.Optical clarity 2.High gloss 3. FDA grades available 4. Low cost 5.Good dimensional stability 6.Good rigidity | 1.Household goods 2.Containers 3.Furniture 4.Housings 5.Packaging |

Polyetherimide (PEI) | Thermoplastic with high heat resistance and excellent mechanical properties. | 1.High heat resistance 2.Exceptional strength and impact modulus 3.High dielectric strength 4.Broad chemical resistance 5.Biocompatible 6.Excellent machinability and finishing characteristic 7.Outstanding processability on conventional mold equipment 8.Flame resistance withlow smoke evolution | 1.Commercial aircraft interiors 2.Healthcare products 3.Cooking utensils 4.Fiber optics 5.Electrical products 6.Electronic parts |

Product packaging

Factory Show

Company Profile

FAQ

Q1: Are you trading company or manufacturer ?

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 15-25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail,

packing detail and so on.

We will supply you a video for production process detail include process report, products size structure and surface detail,

packing detail and so on.

Q6. How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products .

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Похожие товары

Alibuy 1688 taobao pinduoduo JD онлайн-сервис для покупок по индивидуальному заказу доступный товар на рынке Гуанчжоу

635,71 ₽

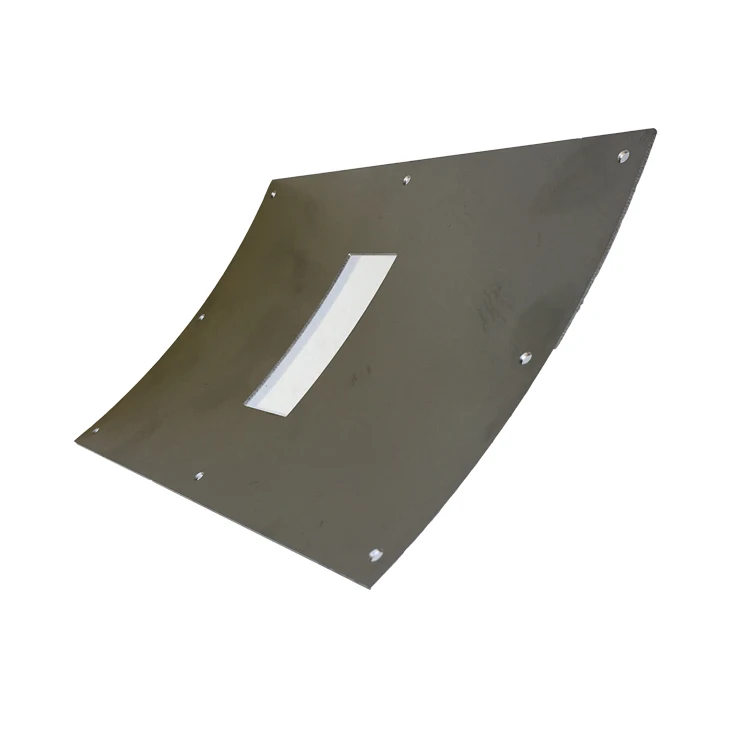

Пользовательские штампованные пластины детали из листового металла образующие металл углеродистая сталь алюминий

25,43-127,15 ₽

Кованые Цепи Крепление Ratchet Type Load Binders With Hook

Пластиковый паук Кола

Китайский поставщик быстрый прототип abs-силикона силиконовой формы пластиковый профессиональный станок с ЧПУ

127,15-241,57 ₽

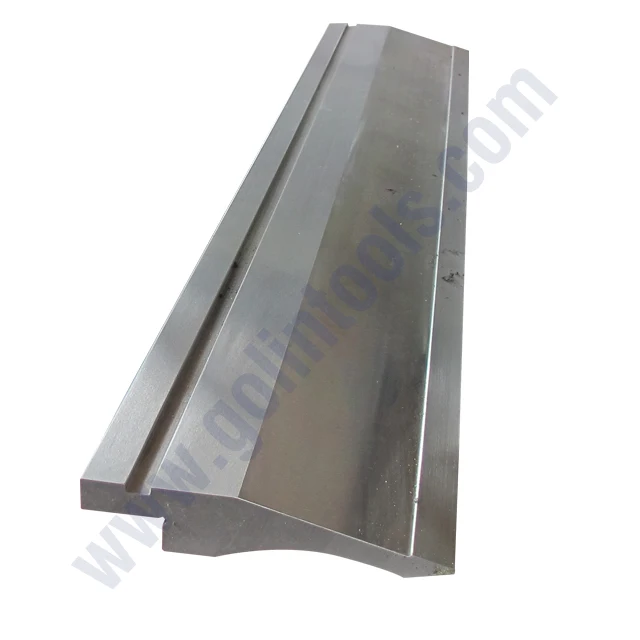

AMADA-GL 10906 пресс листогибочный оснастки

Оптовая продажа немецкая стандартная HASCO вставка с датой регулируемая штамп пластиковые детали сменные для изготовления

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $