Машина для производства Цементных сайдинговых плит Xps пеноизоляционные плиты Eps цементные сэндвич панели резки цементных бетонные стеновые панели

- Категория: >>>

- Поставщик: Guangxi Hongfa Heavy Machinery Co. Ltd.

Сохранить в закладки 1601249741635:

Описание и отзывы

Характеристики

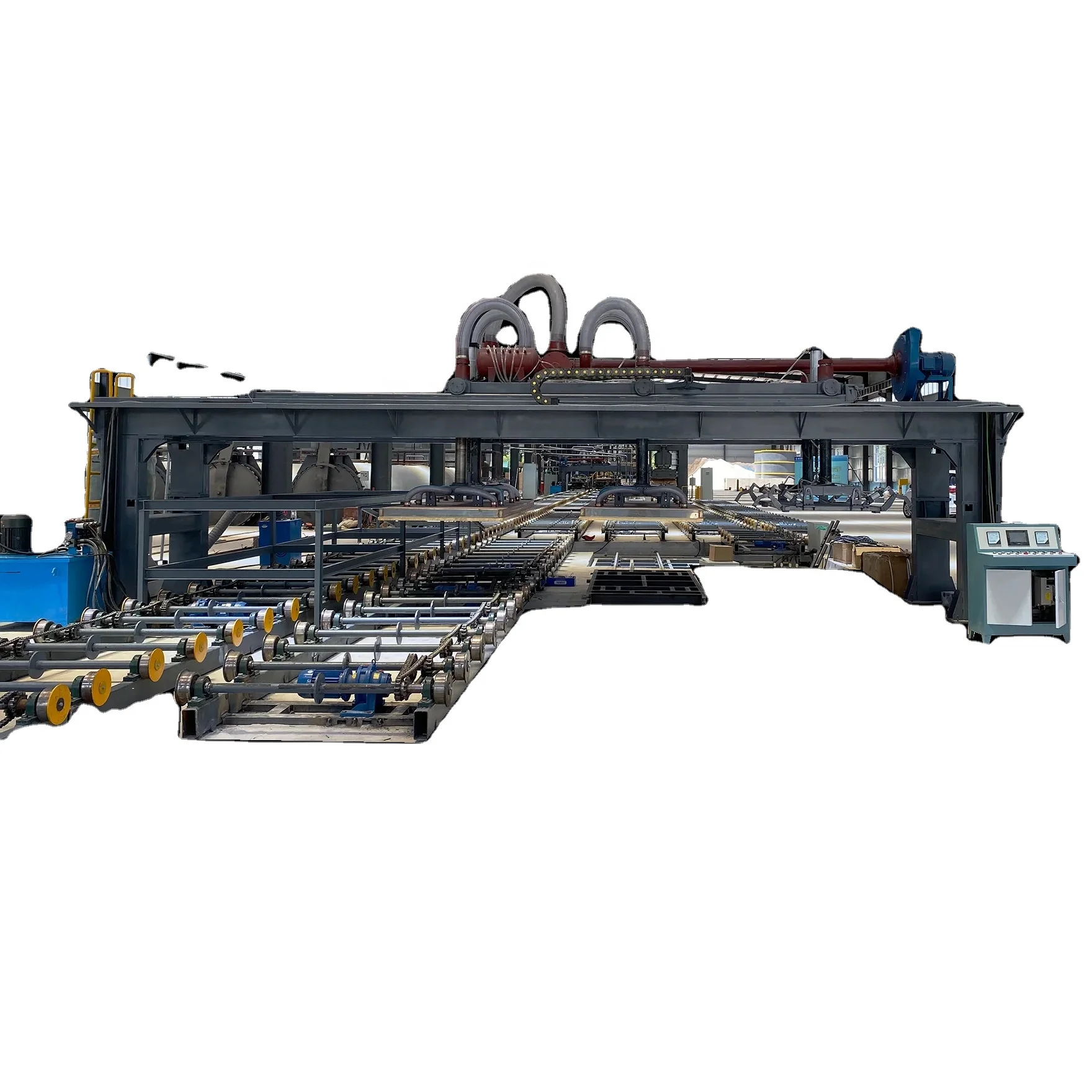

Precast Concrete Wall Panel Making Machine

Sandwich Wall Panel Machine/Cement Foam Panel Production Line

HONGFA manufactures 3 types production line for precast concrete wall panel. They are manual, semi automatic and automatic style. The capacity can be customized from 50000m2 to 1000000m2, more capacity more forming machine. Except for manufacturing machines, HONGFA is the only one company in China market which produce both panels and machines, with more than 7 years panel production experience, we will support you from machine setting to formula and concrete wall panel machine installation on site.

Foam Sandwich Plate Machine Precast Concrete Wall Panel Production Line Sandwich Panel Factory Fireproof EPS Lightweight PanelPrecast Concrete House Molds Modular House Concrete Board Production Line Panel Machine Cement Board Making Machine

HONGFA Wall Panel and Molding Car Details | |||

Applicated panel types | EPS concrete solid panel & hollow panel, gypsum panel, foam panel. It can be with or without calcium silicate board and fiber cement board. | ||

Panel usage on construction | Interior wall, exterior wall, roof, floor etc. | ||

Panel raw materials | Cement, EPS, sand, water, latex powder, water reducer, fiber cement board. | ||

Panel density | 500-800kg/CBM, you can control density via adjusting formulas. | ||

Panel length/width | Length usually is 2000,2270,2440,2700,2800,2850,3000mm etc based on requirements. Popular width is 600mm and 610mm. | ||

Thickness | 60, 75, 90, 100, 120, 150, 200,250mm etc. | ||

Strength | 3-6Mpa. | ||

Size of machine | 2750*2504*1359mm | ||

HFP530A Automatic Molding Car Parameter and Productivity | ||||||||

Overall Dimensions(mm) | Power(KW) | Output / panels quantity per molding car | ||||||

60mm | 75mm | 90mm | 100mm | 120mm | 150mm | 200mm | ||

3030*2250*3100mm | 5.5KW Total 80KW | 50pcs | 46pcs | 42pcs | 40pcs | 32pcs | 28pcs | 22pcs |

Other Main Machines for a Complete Production Line: mixer+ eps expander+de-molding+waste recycle unit

1. Mixing plant

HONGFA mixing plant consists of mixer, movable infusion unit and aggregating system. It can mix all raw material automatically and record every data for production. 3.6CBM capacity mixer guarantees infusion efficiency. It only needs about 15seconds to finish a panel with size 2440*610*100mm.

2. EPS Expander

EPS expander is used for expanding raw polysterene, one-time expander can make EPS around 15-18kg/CBM, interval expander can get proportion on 9-11kg/CBM.

3. De-molding machine

De-molding machine can pull the cured panels out deirectly, Hongfa design it based on 6 years panel manufacturing experience, make it possible that demolding machine is movable, after demolding, the molds can be installed immediately without any delay.

Multiwork is possible so efficiency is triple compared to traditional vertical manual and semi horizontal production line.

4. Recycling unit

Recycling unit can save eveything in production, waste slurry settling in underground mixer, the cement and sand will be pumped into mixer again for next mixing cycle. Keep production clean and make waste recycling, cost saving.

5. Hollow core panels unit

If you want hollow core wall panels with thickness above 150mm, HONGFA offers complete system solution. Hollow panels usually use for roof, cladding etc. purpose without any bearing demand.

6. Movable slurry piston pump unit

This unit uses for movable hydraulic slurry infusion, after mixing all raw material in mixer, then slurry pours into this movable

container, it can mix and inject at same time, guarantee slurry not falling down or the heavier material(sand or cement) seperates

from lighter(EPS) one.

A: With concrete

B: With calcium silicate board

C: With EPS grain with holes

D: Gypsum board without holes

E: With ceramsite grain

F: Others

Common Size Of EPS Lightweight Wall Panel: 2.44m*0.6m

Standard Size L*W*H: 2440mm*610mm*50mm

Other Thickness: 60mm/75mm/90mm/100mm/120mm/150mm/180mm/200mm/250mm

Tips: Other size such as length 3000mm, 3200mm, 3500mm, 4000mm can be customized.

Raw Materials Of EPS Wall Panel: fiber cement board, eps, fly ash, cement, sand

Outside (side board): Calcium silicate board or Cement fiberboard

Inside (core material): EPS foam particles, Cement, Sand, Additives (Hydroxypropyl methyl cellulose)

Can also choose other materials like: Industrial Residues, Fly Ash, Slag, which are not only is recyclable and reducing pollution,but also low cost and abundant.

Sanwich Wall Panel with various applications in construction works

Applied range of Sandwich wall panel:

For interior and exterior wall partition on steel or concrete structure building. It can be widely applied to wall materials of various high and low buildings such as bank, office building, hospital, school,hotel, shopping mall, amusement, old house reconstruction, residence and workshop.

Low business risk for establishing the EPS sandwich wall board production factory

(A) long-term stability advantages: Due to trend is from clay to non-clay, from heavy to lightweight, from high to low energy consumption.EPS panel can meet the new requirements. And the raw materials is abundant and low cost. So competitive advantage will be relatively stable and long-term business in the market.

(B) Mechanization in production: Less workers but high output and stability.

(C) It is a comprehensive utilization of the industrial wastes project, and will get a great support from the Government.

EPS Sandwich Wall Panel Advantages

The EPS Wall Panel is widely used for partition board in non-bearing wal, exterior wall in steel structure, roof and floor. it is popularfor new construction or renovation and expansion building, such as house construction, fire walls, fences, footings, retainingwalls, bungalows, high-rise buildings, basements, walk-in fridges, hotels, schools, shopping malls, villas and etc.

Hongfa Technology, Serving The World

Produce the highest quality Sandwich Wall Panel at the lowest cost. Equipped with advanced facility, Hongfa Group provides solutions of the best panel plant for EPS panel.gypsum board, foam cement panel, and precast concrete panel, etc. The annual output can be customizedfrom 50,000 to 1,000,000 m² High capacity High speed materials filling Low labor intensity Easy operation and maintenance High-strength, high-density, and flat & smooth surface EPS panelFlexible to produce all kinds of board.

Customer EPS Wall Panel Plant Successful Projects:

Precast Concrete House Molds Modular House Concrete Board Production Line Panel Machine Cement Board Making Machine

Delivery time: Within 30 days after receipt of deposit and moulds confirmation from buyer of precast concrete wall panel making machinery.

- We have successfully exported and established more than 100 sets of machine in domestic and overseas. So we have many type of business model in other countries.

- Our company has set up office in Vietnam, Indonesia, South Africa and sale service station in Nanning Guangxi province and will ensure the matericals rapid and timely service.

About Hongfa Group

Since 1990, Hongfa Machinery Co., Ltd has been in the field of construction and building materials equipments.

More than 30 years experience. 1500 employee (50+engineers)

4 factories with 440,000m2 and annual sell above USD100 Million.

10,000 customers in over 120 countries.

Continuous service and logistics system.

High quality products and competitive price.

Hongfa Machinery's Honor

1.One of Top Ten Influential Brands in China Brick &Tile Industry

2.High and New Technology Enterprise

3.Famous Trademark of China

4.Star Enterprise with China Patent

5.AAA Grade Credit Enterprise

6.Advanced Exporter in Guangxi Province

7.Advance Quality Management Unit.

Exhibition & Customer Visit

Hongfa, as a top brand enterprise in China, our products are also exported to Russia, Brazil, Thailand, Indonesia, Vietnam, Angola, Bangladesh, India, Australia, Sudan, etc., 96 countries and regions, deeply welcomed by clients from all around the world.

Q: Are you manufacturer or trading company?

A: We are one of biggest drect factory in West-South of China with more than 20+ agents in domestic market, the quality and after-sale services is guaranteed as we are Chinese Trustworthy Old Brand machinery enterprise since 1990s.

Q: How long is the warranty of your equipment?

A: For the core components of the main machine, we provide 1 year guarantee, but the exist machine of our customer's, they have operating for more than 10 years, it still runing without problems.

Q: Can this machine make other size product?

A: All along we insist on inovating and developing new equipments for construction building industrial, we are available to design and do the mould according to customer's Drawing or as ours.

Q: When do you delivery the goods?

A: Normally 30 days after receipt of deposit and moulds confirmation from Buyer.

Q: What about the payment?

A: 30% as down deposit by T/T ,70% as the balance paid by T/T before loading(L/C is also acceptable).

Q: What does the total price include?

A: After some simple communication, we will make the plan according to you target on Capacity and budget. Then we will send the accurrate quotation for you shortly.

Foam Sandwich Plate Machine Precast Concrete Wall Panel Production Line Sandwich Panel Factory Fireproof EPS Lightweight Panel

Похожие товары

Оборудование для производства Композитных плит

Полностью Автоматическая технология горячего расплава EPS оборудование для производства сэндвич-панелей крупносерийного

Сборная бетонная тротуарная плита Серии Lf формовочная машина/Оборудование для производственной линии

Стеновые панели 2440 мм и 3000 делая машину изолированные стеновые декоративные машины заводская цена для бунгало

Машина для изготовления потолочной плитки из гипсокартона/Sheetrock/гипсокартона

Машина для производства гипса

Машина для производства гипса

Новые поступления

Новинки товаров от производителей по оптовым ценам