Лазерная сварка 3 в одной машине 3000 Вт робот лазерная сварочная машина алюминий с сертификатом CE

- Категория: >>>

- Поставщик: Shandong Leapion Machinery Co. Ltd.

Сохранить в закладки 1601249807598:

Описание и отзывы

Характеристики

Product Description

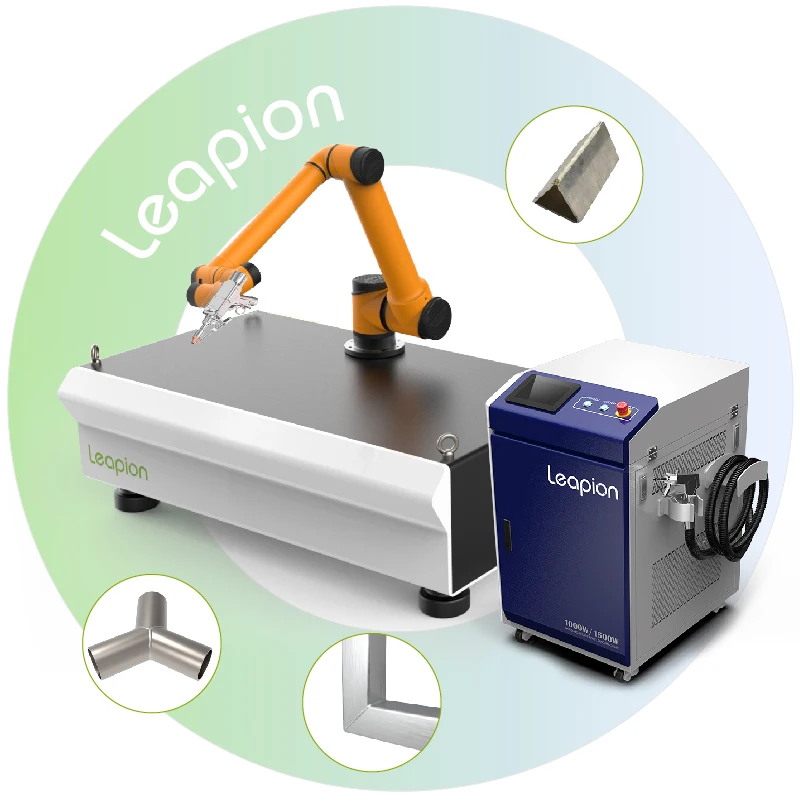

LW-R3 Robot Laser Welding Machine

3 in 1 Function 3000W

3 in 1 Collaborative Robot can provide an high precision and high quality to the customers in the Metal Processing Industry. It is manipulated by the computer and controllers directly, more easy to operate, which can realized the automatic work, provide multiple plans and highly improve the efficiency. With 3 in 1 functions, it also can realized cutting, welding and cleaning functions in 1 machine. Therefore, it also can save your cost of equipment and worker wages to be your best choice.

Collaborative Robot VS Traditional Robot Arm | ||||

Safety | Work with Person | Work only in fences | ||

Usage | Hand simple programming | 3D modeling software programming | ||

Flexibility | Lightweight, mobile, easy to install, plug and play | Poorly adapted to the environment | ||

Applications | Industry and Home using | Only industry using | ||

3 in 1 Funtions

Welding Function

The laser welding machine has fast welding speed and improves welding efficiency. Good welding effect, improve the yield rate. Easy to operate, inexperienced people can quickly learn how to operate the equipment within 5 minutes, saving labor costs for

factories.

factories.

Cutting Function

Change the parameters in the control panel, and choose the nozzles for cutting, the machine can be switched to the cutting mode.It is able to cut thin metal sheets easily and quickly, speeding up factory production efficiency.

Cleaning Function

The cleaning function is available by replacing the front of the laser head and switching the control panel to cleaning mode. Laser cleaning can quickly remove rust from metal surfaces, and factories that process carbon steel will often use this function.

Collaborative Robot

Robot Mode Option | i5 | i10 (standard) | i16 |

Loading Weight | 5kg | 10kg | 16kg |

Robot Weight | 24kg | 38.5kg | 38kg |

Repeat Accuracy | ±0.02mm | ±0.03mm | ±0.03mm |

Working Radius | 886.5mm | 1350mm | 967.5mm |

Sample and Machine

Product Parameters

Model | LW-R-3 Collaborative Robot Welding Machinewith 3 in 1 Laser Function |

Laser Power | 3000w (Option: 1000w, 1500w, 2000W,3000w) |

Laser Fiber Wire Length | 10 m |

Laser Output Power Adjustment Range | 10% - 100% |

Laser Source | MAX (Option: Raycus, IPG, BWT, Reci) |

Welding Ability | Stainless steel 8mm, carbon steel 8mm, galvanized plate 8mm, aluminum plate 6mm |

Control System | Raytools (Option: Relfar, Gefasst) |

Control Panel | Touch Screen 7 inch |

Support Languages | 18: Chinese Simplified, Chinese Traditional, English, Polish, Turkish, Arabic, Japanese, Korean, German, Spanish, Russian, French,Portuguese, Italian, Hungarian, Czech, Finnish, Vietnamese |

Auto Wire Feeder | Single Type, Load Weight 20KG |

Cooling Method | Water Cooling |

Auxiliary Gas | Nitrogen or Argon gas Note: Cleaning mode can use compressed air |

Voltage | 380V 3PH 50HZ/60HZ (Option: 440V) |

Package Dimension | 1460*1260*860mm (Table and Robot) 160*960*1360mm (Welding Machine) |

Package Weight | Total 1050KG (800kg and 250kg) |

Laser System

Laser Source

Professional welding laser source, small in size, light in weight, and easy to move. The light emitting mode is more conducive to

achieve a good welding effect. Support laser powers from 1kw to 3kw.

achieve a good welding effect. Support laser powers from 1kw to 3kw.

Laser Head

The laser generated by the laser source is transported to the welding head, then is collected and reflected by a reflector and

focused by the focusing lens to reach the nozzles and finally fired to the materials.

focused by the focusing lens to reach the nozzles and finally fired to the materials.

Control Cabinet

With neat control cabinet internal wiring, International top-brand electrical components and pneumatic components. At the same

time, given our customers best user experience for a long warranty period.

time, given our customers best user experience for a long warranty period.

Control Switch

Simplified switch system, only one power switch, saving the operator's time. The emergency stop switch protects the operator and

quickly stops the equipment from working.

quickly stops the equipment from working.

Control Panel

Touch screen makes you change the parameters quickly when wearing gloves. Multiple sets of parameter can be saved, and there is no need to adjust again for multiple welding times in the future after one test.

Water Chiller

When using an industrial chiller, pure water is used in summer, and antifreeze is used in the water when the room temperature is below 5 degrees Celsius . Switch back to pure water when the temperature warms up.

Wire Feeder

With Standard automatic wire feeding system and dual motors, The forward and reverse and the speed of wire feeding can be adjusted

through the control panel.

through the control panel.

Note: Standard is Single Feeder.

Consumable Parts

Nozzle

Different shapes of nozzles are suitable for different jobs. It need chooses the right wire material when used with a wire feeder.

When switching to cutting mode, a special nozzle for cutting is required.

When switching to cutting mode, a special nozzle for cutting is required.

Lens

There are Protective Lens, Focal Lens and Reflective Lens inside the Laser Head. Normally, Protective Lens are the wearing parts, when working after a long time, the user may need to change new lens to continue to work.

Application Industry

Kitchen and bathroom industry, advertising industry, door and window industry, mold industry, stainless steel products industry, handicraft industry, furniture industry, home appliance industry, auto parts industry, etc.

Product Shipment

Shipment Method | Sea freight, Land freight, Air freight etc.The total weight and dimension is too big, not recommend to use express as the shipment method. |

Package Method | Wooden Case |

Noted | If you need to ship by air, please let us know before purchase, and you need to empty the gas in the water cooler before shipment. And there have the motor inside the machine, therefore if use the Air shipment, it has to make the "Electromagnetic inspection", which cost around 80USD per time. |

Quality Test

Certifications

Warm Tips

If you need us to make the corresponding certification. Please inform Leapion's sales staff and we will do our best to cooperate and provide maximum support to you.

Why Choose Leapion Laser?

Precision Engineering & Operational Efficiency: Leapion's laser welding technology combines power and precision. With settings from 1000W to 3000W, it achieves up to 0.5mm accuracy. Fast speeds, up to 120 mm/s, enhance productivity without sacrificing quality.

Ease of Use & Intuitive Design: Leapion delivers a user-friendly welding tool. The welder gun is lightweight and ergonomic. Its touchscreen is intuitive, making the setup quick. Operators can master it with just a little training. It also ensures comfort for the user during long-term use.

Cost-Effectiveness & Comprehensive Service: Leapion offers competitive prices. The operating costs are low. Its machines include safety features like overheat protection and emergency stops. We provide comprehensive after-sales services. These include training, maintenance, and technical support. This gives our customers confidence.

Safety Standards & Environmental Considerations: Leapion prioritizes safety. Each machine has key safety features to safeguard users and the environment. laser welding machine by Leapion cut down on waste and emissions. This supports eco-friendly operations.

Customer Satisfaction & Innovation Leadership: Leapion earns praise across sectors for its focus on quality and efficiency.Leading in innovation, Leapion keeps improving its laser welding technology. It strives to meet modern manufacturing's changing needs.

Reliability, Longevity & Quality Materials: Leapion's welding machines are robust and long-lasting, crafted from high-quality stainless steel. They promise a lengthy lifespan with minimal upkeep. These machines run quietly, creating a better work atmosphere.

Ease of Use & Intuitive Design: Leapion delivers a user-friendly welding tool. The welder gun is lightweight and ergonomic. Its touchscreen is intuitive, making the setup quick. Operators can master it with just a little training. It also ensures comfort for the user during long-term use.

Cost-Effectiveness & Comprehensive Service: Leapion offers competitive prices. The operating costs are low. Its machines include safety features like overheat protection and emergency stops. We provide comprehensive after-sales services. These include training, maintenance, and technical support. This gives our customers confidence.

Safety Standards & Environmental Considerations: Leapion prioritizes safety. Each machine has key safety features to safeguard users and the environment. laser welding machine by Leapion cut down on waste and emissions. This supports eco-friendly operations.

Customer Satisfaction & Innovation Leadership: Leapion earns praise across sectors for its focus on quality and efficiency.Leading in innovation, Leapion keeps improving its laser welding technology. It strives to meet modern manufacturing's changing needs.

Company Introduction

Customer Service and Support

1.Pre-Sales Service

Expert Consultation: Our team specializes in detailed consultations. We guide you through our high-quality laser welders. Our goal is to understand your needs and suggest ways to boost your efficiency.

Hands-On Demos: See Our laser welding excellence yourself. Our demos show off our welders' advanced features. You'll see the quality and precision that distinguish our products.

2.During Sales Service

Customized Setups: We work with you to design laser welding solutions tailored to your workflow. This ensures your welder delivers optimal performance and quality.

In-Depth Training: Unlock the potential of our laser welders. Our training programs aim to make your team experts in cutting-edge welding techniques for peak productivity.

3.After-Sales Service

24/7 Technical Support: Our outstanding service includes all-day support. We keep your operations smooth, without interruptions.

Maintenance and Repairs: Extend your welder's life with our regular maintenance and prompt repair services. We minimize downtime and protect your investment.

2.During Sales Service

Customized Setups: We work with you to design laser welding solutions tailored to your workflow. This ensures your welder delivers optimal performance and quality.

In-Depth Training: Unlock the potential of our laser welders. Our training programs aim to make your team experts in cutting-edge welding techniques for peak productivity.

3.After-Sales Service

24/7 Technical Support: Our outstanding service includes all-day support. We keep your operations smooth, without interruptions.

Maintenance and Repairs: Extend your welder's life with our regular maintenance and prompt repair services. We minimize downtime and protect your investment.

FAQ

1. What is the MOQ?

The minimum order is 1 unit. For customers who need to customize the logo, the MOQ is also 1 unit, and for customers who need to modify the exterior color, the MOQ is also 1 unit, but the production time will be longer.

2. What terms of trade are offered?

Leapion can provide suitable terms according to your specific needs, including: EXW, FOB, CFR, CIF, DAP, DDP, etc.

3. What payment methods are accepted?

We accept: credit card, debit card, bank transfer, L/C, etc. You are welcome to pay us through Alibaba's "Trade Assurance Order", which can guarantee your rights and interests.

4. How to get sample testing service?

Please send us the DXF. format to make the welding test for you.

We provide three options for sample testing service.

① If you don't need us to mail the tested samples to your address, and we have the metal materials you need to tested in stock, then we offer free testing service. Simply contact us with your specific needs. We will send you the test pictures and videos within 5 working days.

② if you need us to send the tested samples by Express, please pay the express fee.

③ If you need special metal samples for testing, please send the samples to our address or pay us the cost for purchasing metal materials.

5. How to confirm the most suitable model of equipment for me?

We suggest you can contact us, Leapion will provide you 1 to 1 VIP service, professional sales staff will recommend the most suitable equipment for you. For faster communication, we recommend that you confirm the following information before contacting us:

① which metal material you need to welding

② the maximum thickness of each metal material

③ the voltage of your local factory

④ the trade terms you required

⑤ Required Time

Похожие товары

Китай заводская цена станция для сварочного аппарата батареи призматической цилиндрической ячейки с лезвием технической поддержкой

1 209 109,75 ₽ - 1 331 130,00 ₽

Портативная ручная импульсная машина для удаления ржавчины и металлических линз 1000 Вт 2000 цена

221 855,00 ₽ - 332 782,50 ₽

33% проехали! Заводская цена промышленная мойка для моркови манго картофеля маниоки Вихревой тип фруктовый овощной салат стиральная машина

55 033,45 ₽ - 110 066,90 ₽

6 оси мини автоматическая рука робота/роботизированная промышленный/робот сварочный робот

2 421 471,80 ₽ - 2 861 739,40 ₽

Лазерная сварочная машина для ювелирных изделий

981 708,38 ₽ - 987 254,75 ₽

Горячая продажа 200 Вт 300 золото серебро лазерная паяльная машина портативный лазерный сварочный аппарат цена

372 906,66 ₽ - 416 933,42 ₽

4 в 1 1500 Вт 1000 2000

277 318,75 ₽ - 332 782,50 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $