Зеленый карбид кремния керамическое остекление зеленый 98% Sic

- Категория: >>>

- Поставщик: Zhengzhou Xinli Wear Resistant Material Co. Ltd.Zhengzhou Ltd.

Сохранить в закладки 1601251613363:

Описание и отзывы

Характеристики

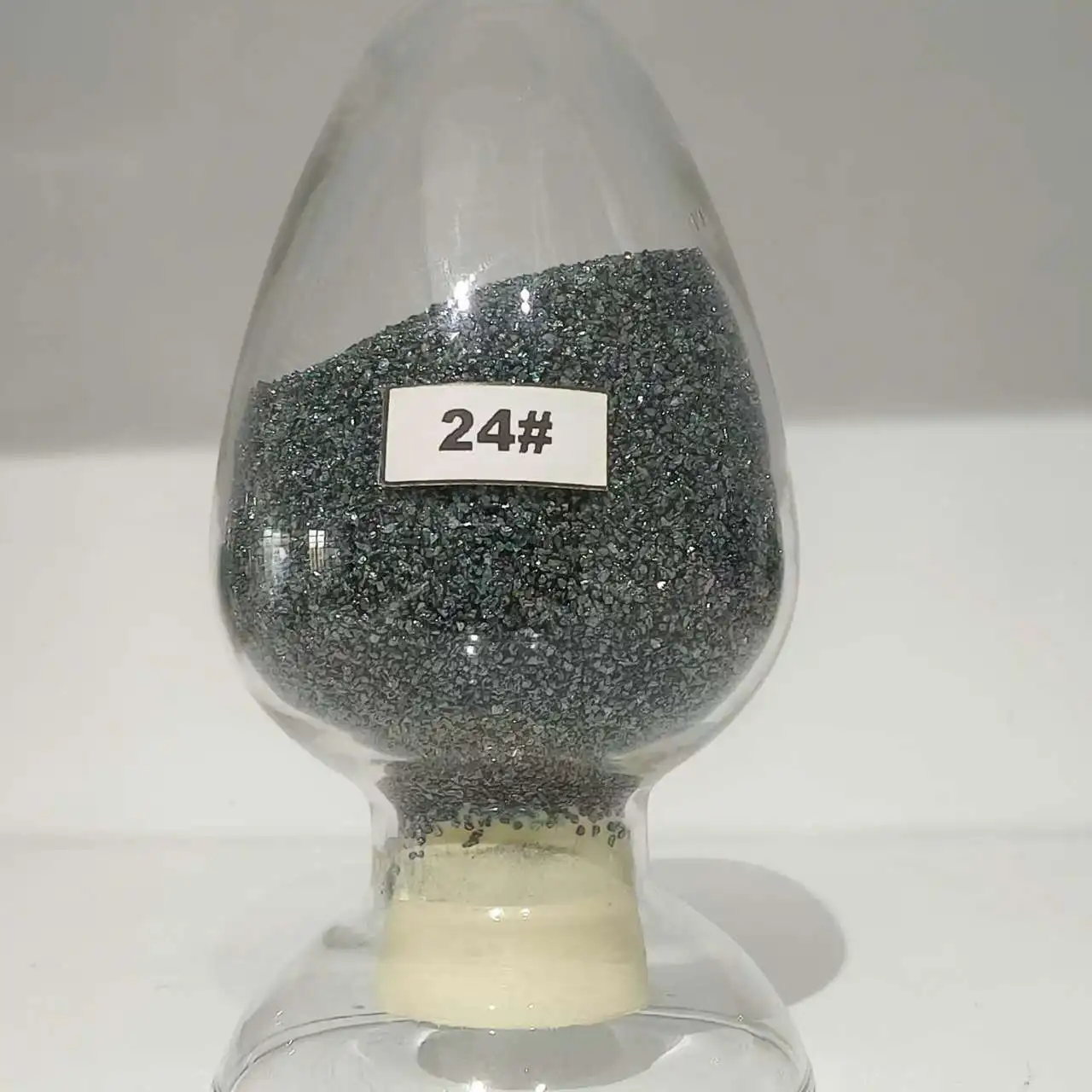

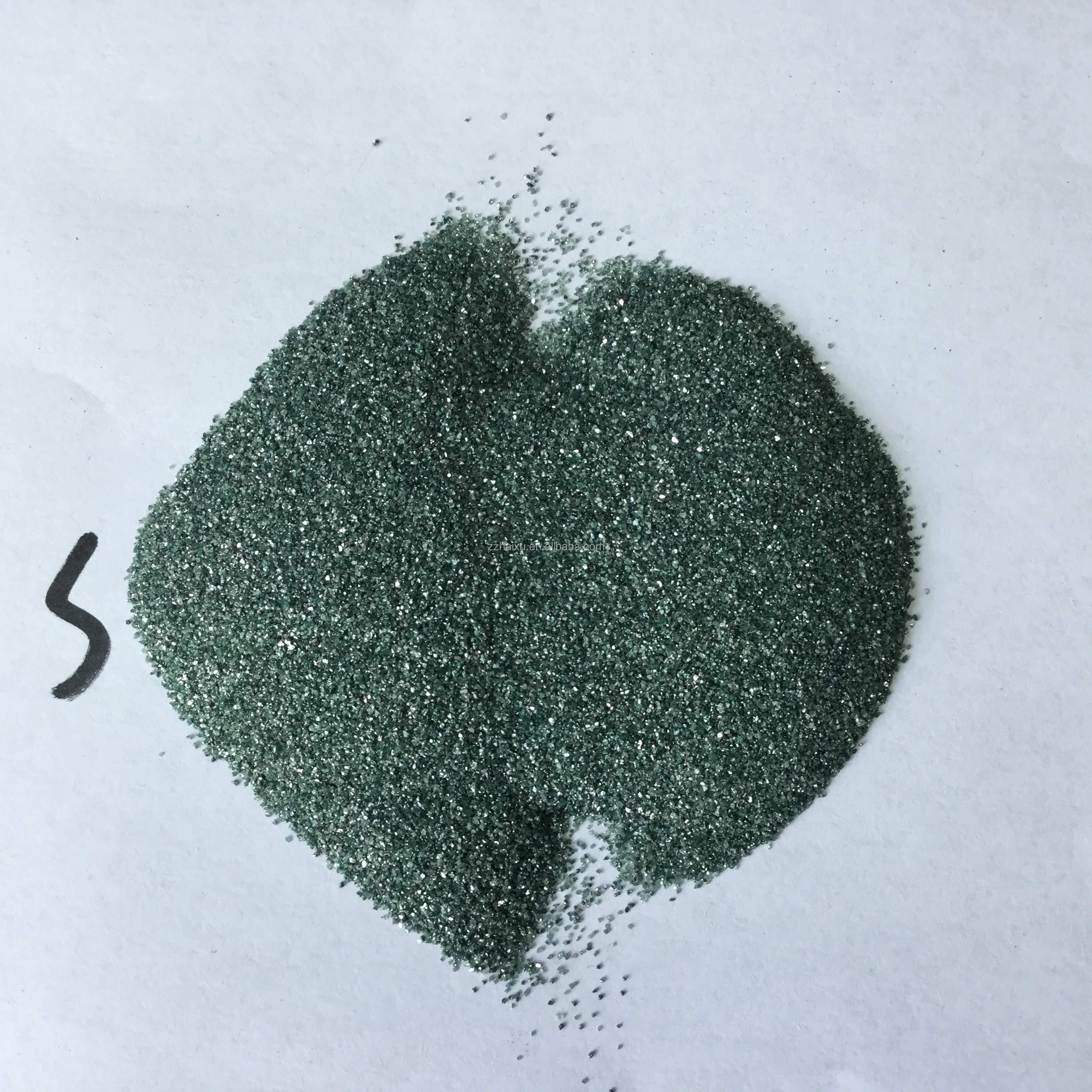

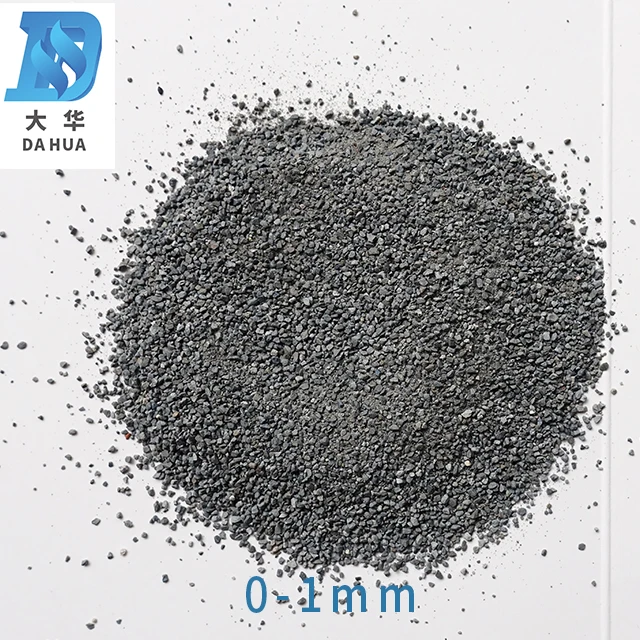

Green silicon carbide

Green silicon carbide is made of quartz sand and petroleum coke through high-temperature melting. The production method is basically the same as that of black silicon carbide, but the requirements for raw materials are different. The smelted crystals have high purity, high hardness and strong cutting force, and are suitable for processing hard and brittle materials. Green silicon carbide is suitable for grinding hard alloys, hard and brittle metals and non-metallic materials, such as non-ferrous metals such as copper, brass, aluminum and magnesium, and non-metallic materials such as precious stones, optical glass and ceramics.

Features

1. Large furnace smelting, long smelting time, sufficient crystallization, large crystal particles, high purity and less impurities;

2. Equipped with international advanced Coulter particle size detector;

3. The company's laboratory has been certified by the government's Import and Export Inspection and Quarantine Bureau;

Green Silicon Carbide Specifications

| Physical property | |

| Crystal shape | Hexagonal |

| Bulk density | 1.55-1.20g/cm3 |

| Grain density | 3.90g/cm3 |

| Mohs Hardness | 9.5 |

| Knoop Hardness | 3100-3400 Kg/mm2 |

| Shatter strength | 5800 kPa·cm-2 |

| Color | Green |

| Melting point | 2730℃ |

| Thermal conductivity | (6.28-9.63)W·m-1·K-1 |

| Linear expansion coefficient | (4 – 4.5)*10-6K-1(0 - 1600 C) |

F16~F220

Chemical Composition

| Size | SiC (%) | F.C (%) | Fe2O3(%) |

| F80 | 99.32 | 0.18 | 0.17 |

| F120 | 99.24 | 0.19 | 0.19 |

| F150 | 99.21 | 0.20 | 0.21 |

| F220 | 99.16 | 0.21 | 0.20 |

Bulk Density

| Size | Ordinary Bulk Density g/cm3 | High Bulk Density g/cm3 | Size | Ordinary Bulk Density g/cm3 | High Bulk Density g/cm3 |

| F16 ~ F24 | 1.38~1.46 | ≥1.46 | F100 | 1.37~1.45 | ≥1.45 |

| F30 ~ F40 | 1.41~1.49 | ≥1.49 | F120 | 1.35~1.43 | ≥1.43 |

| F46 ~ F54 | 1.40~1.48 | ≥1.48 | F150 | 1.31~1.38 | ≥1.41 |

| F60 ~ F70 | 1.40~1.48 | ≥1.48 | F180 | 1.28~1.38 | ≥1.38 |

| F80 | ≥1.46 | ≥1.46 | F220 | 1.36~1.36 | ≥1.36 |

| F90 | ≥1.45 | ≥1.45 |

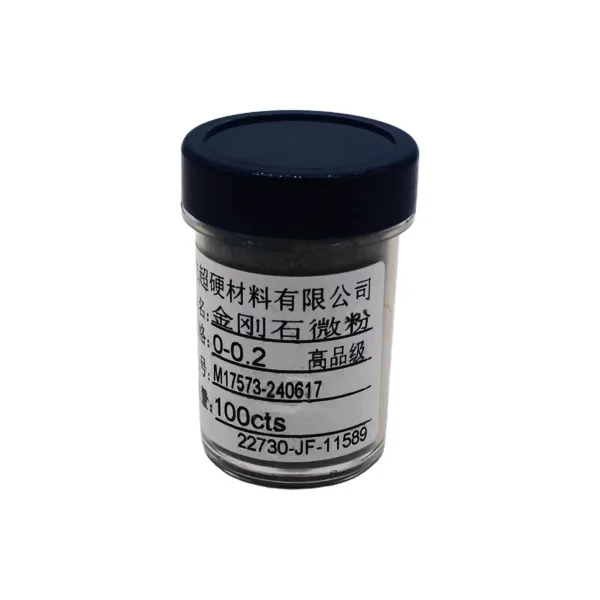

Micropowder for electronic engineering - Japan JIS standard

Features

1. Narrow particle size distribution, sharp particle shape, high purity chemical composition;

2. FEPA standard micropowder is also available;

3. The chemical composition and strength distribution can be customized according to customer requirements.

#700 ~ #3000

| Size | Grain distribution | Chemical Composition(%) | |||||

| D0 ≤ | D3 ≤ | D50 | D94 ≥ | SiC ≥ | F.C ≤ | Fe2O3≤ | |

| #700 | 38 | 30 | 17±0.5 | 12.5 | 99.00 | 0.15 | 0.15 |

| #800 | 33 | 25 | 14±0.4 | 9.8 | 99.00 | 0.15 | 0.15 |

| #1000 | 28 | 20 | 11.5±0.3 | 8.0 | 98.50 | 0.25 | 0.20 |

| #1200 | 24 | 17 | 9.5±0.3 | 6.0 | 98.50 | 0.25 | 0.20 |

| #1500 | 21 | 14 | 8.0±0.3 | 5.0 | 98.00 | 0.35 | 0.30 |

| #2000 | 17 | 12 | 6.7±0.3 | 4.5 | 98.00 | 0.35 | 0.30 |

| #2500 | 14 | 10 | 5.5±0.3 | 3.5 | 97.70 | 0.35 | 0.33 |

| #3000 | 11 | 8 | 4.0±0.3 | 2.5 | 97.70 | 0.35 | 0.33 |

Special micropowder for engineering ceramic materials - FEPA standard

Features

1. The product has high purity and round grain shape;

2. It is suitable for the manufacture of various mechanical shaft seal components, various wear-resistant and corrosion parts, bulletproof armor, high-temperature gas molten metal screen and other advanced engineering materials.Chemical Composition

| Size | SiC ≥ % | F.C ≤ % | Fe2O3≤ % | Size | SiC ≥ % | F.C ≤ % | Fe2O3≤ % |

| F230 | 99.20 | 0.15 | 0.15 | F800 | 98.00 | 0.25 | 0.25 |

| F240 | 99.20 | 0.15 | 0.15 | F1000 | 96.50 | 0.30 | 0.30 |

| F280 | 99.20 | 0.15 | 0.15 | F1200 | 95.30 | 0.30 | 0.30 |

| F320 | 99.00 | 0.15 | 0.18 | F1500 | 94.80 | 0.30 | 0.30 |

| F360 | 99.00 | 0.20 | 0.18 | F2000 | 94.50 | 0.33 | 0.30 |

| F400 | 98.80 | 0.20 | 0.18 | F2500 | 94.30 | 0.33 | 0.33 |

| F500 | 98.80 | 0.20 | 0.25 | F3000 | 94.30 | 0.33 | 0.33 |

| F600 | 98.50 | 0.25 | 0.25 |

Applications

1.Refractory,Furnace Burden,Castable,Ramming Compoynd,Refractory Bricks etc

2.Blasting,surface Treatment,Rust Removal

3.Cusmetics products manufacturing,Beauty crafts and Dermabrasion etc

4.Ceramic products

5.Grinding wheels,sandpaper etc

6.Glaze,floor coating,Floor / Wall Laminates

7.raw material of Knife Grinder,Whetstone,oilstone,grinding stone,abrasive stones and so on

8.Used to produce Polishing wax,polishing fluid,grinding powder,grinding fluid and so on

9.Wear-resisting floor,coating,painting etc

10.Brake linings

Packing Details

1ton/jumbo bag

Jumbo bag + Wooden pallets

25kgs/bag, 40 bags/jumbo bag

25kgs/woven bag or kraft paper bag

All package can be customized according to customers' requirements

Zhengzhou Xinli Wear-resistant Materials Co. Ltd. was founded in 1996. It is a professional factory that engaged in various abrasives production, R&D and sales. The annual output of Xinli is 3,000 Tons micro powder, and it is the first enterprise in China to achieve the standard of the original grain size to 0.3μm, can achieve the effect of metal mirror polishing.

The company has passed iso9001:2015 quality management system certification. It has 2 dumping furnaces and 3 fixed furnaces, 12000V magnetic separator, ball mill, Bamako, OMAX resistance and laser particle size detector and other advanced production equipment and testing instruments. Adhere to innovation, standardized, refined production, so that every customer can use stable quality, price concessions products is our consistent goal!

Q: Are you a trading company or manufacturer?

A: We are a manufacturer enterprises of abrasives over 20years.our products have competitive price and quality guarantee. Welcome to send your inquiry!

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but you need to pay the cost of freight.

Q:How can I get the new price of a product?

A: Please provide the exact or approximate quantity, packing details, destination port or special requirements, then we could give you the price accordingly.

Q:How do you guarantee the product quality?

A: We have the quality control system ISO9001:2008, and it's been followed strictly. We also have the professional QC team, and each our package worker will be in charge of the final inspection according to the QC instruction before packing.

Q: How long is the lead time?

A: Except OEM products, generally 5-7 days for trial order, 10-20 days for mass order once deposit received.

Q:How about your after-sale service ?

A: If any technical or quality problem after you receive the cargo, you can contact us any time.If the problem caused by us, we will send you free goods for replacement or refund your loss.

Q:Can we have a visit to your factory?

A:You’re warmly welcoming to visit our plant. And please inform me of your scheduled time in advance, we’ll pick you up and arrange the agenda for you.

Q:Can I use my own design package?

A:Yes, The package can be with your logo.

Похожие товары

Зеленый карбид кремния sic для керамического парового котла

Прямая продажа китайский завод промышленный алмазный абразивный порошок цена синтетические алмазные Порошковые шлифовальные клапаны

Абразивы из карбамида и формальдегида

Заводская цена, нано-карбид кремния, порошок, цена, сырье из карбида кремния с 99% чистотой

Заводская поставка черный порошок карбида кремния размер частиц 80 карбид

Тротуарное покрытие и постельное белье цвета вулканических пород можно настроить ландшафтный дизайн Красной вулканической породы

Циркониевый корундовый абразивный циркониевый оксид 24 Сетки 46

Новые поступления

Новинки товаров от производителей по оптовым ценам