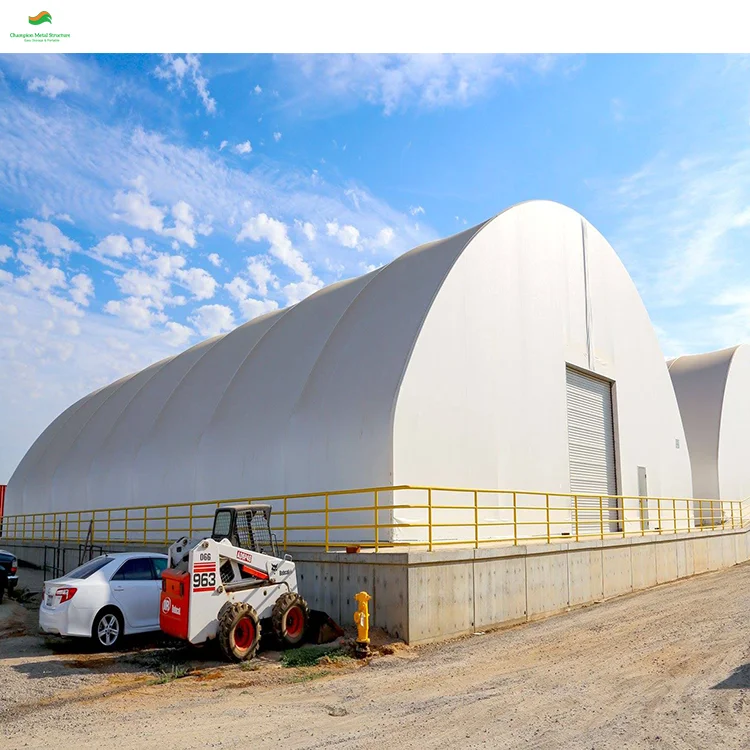

Палатка для временного хранения событий 25x40 м с высокой устойчивостью к ветровой и снежной нагрузке предназначена коммерческих решений хранения.

- Категория: >>>

- Поставщик: Hunan Champion Metal Structure Co. Ltd.Hunan Ltd.

Сохранить в закладки 1601252185411:

Описание и отзывы

Характеристики

A fabric building is a type of structure that uses fabric, usually made of durable materials like polyethylene, PVC, or other

synthetic textiles, as its primary exterior covering. These buildings can be used for a variety of applications, including

agricultural storage, industrial facilities, sports complexes, and event spaces. ### Key Features of Fabric Buildings:

synthetic textiles, as its primary exterior covering. These buildings can be used for a variety of applications, including

agricultural storage, industrial facilities, sports complexes, and event spaces. ### Key Features of Fabric Buildings:

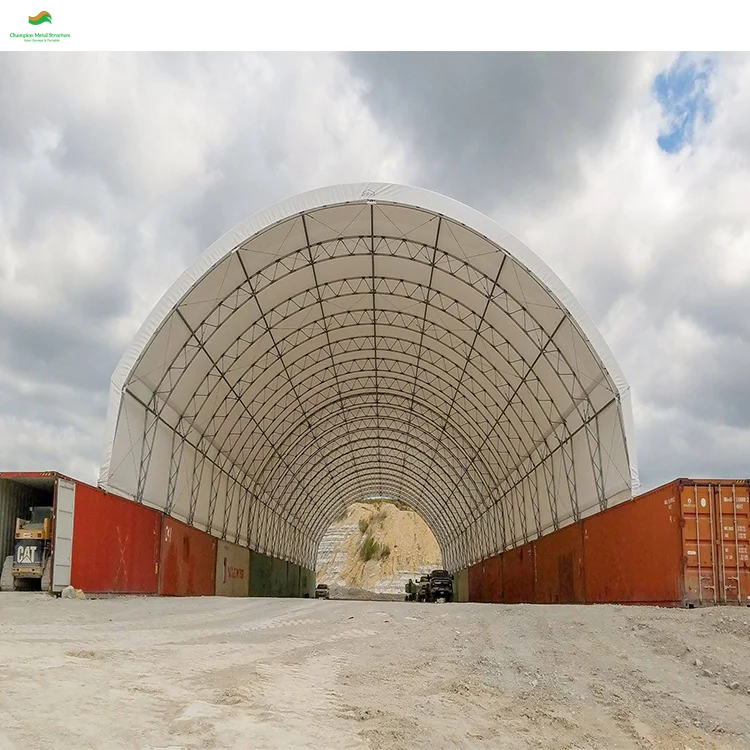

1.**Structure**:

Fabric buildings typically have a frame made of steel, aluminum, or other materials, which supports the fabric

covering. The design can be temporary or permanent, depending on the intended use.

covering. The design can be temporary or permanent, depending on the intended use.

2. **Lightweight**:

The materials used in fabric buildings are generally lighter than traditional building materials, making them easier to transport and install.

3.**Versatile Designs**:

Fabric buildings can be customized in size, shape, and layout to fit specific needs, making them suitable

for a wide range of functions.

for a wide range of functions.

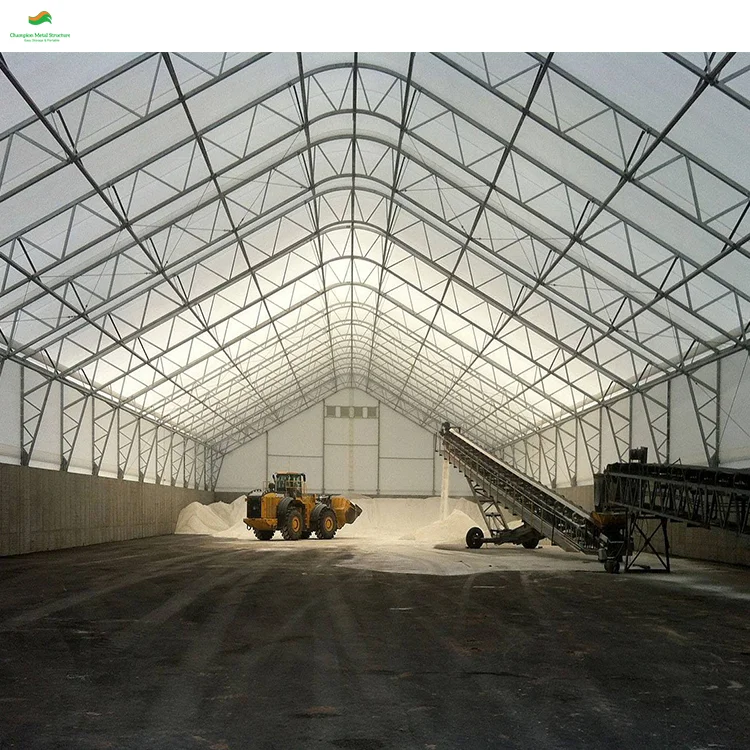

4. **Natural Lighting**:

Many fabric structures allow for natural light to enter, reducing the need

for artificial lighting and creating a more pleasant environment.

for artificial lighting and creating a more pleasant environment.

5. **Cost-Effective**:

They can be more affordable to construct and maintain than traditional buildings, particularly for large spaces.

### Advantages of Fabric Buildings:

1. **QuickInstallation**:

Fabric buildings can often be erected in a shorter time frame compared to conventional structures, making them

ideal for urgent needs.

ideal for urgent needs.

2. **Energy Efficiency**:

he insulation properties of certain fabric materials can help maintain

temperature, potentially reducing heating and cooling costs.

temperature, potentially reducing heating and cooling costs.

3. **Durability**:

High-quality fabric can withstand different weather conditions, including wind, rain, and snow, depending on the design and construction.

4. **Flexibility**:

Fabric buildings can be designed to be demountable, allowing for relocation or reconfiguration as needs change.

5. **Low Maintenance**:

Thesestructures typically require less maintenance than traditional buildings, and the materials are resistant to corrosion.

6.**Sustainability**:

Many fabric buildings can be designed with eco-friendly materials and practices in mind, contributing to

sustainable construction efforts.

sustainable construction efforts.

7. **Enhanced Airflow**:

The design often promotes better ventilation, which can be beneficial

for certain applications, such as agricultural uses.

for certain applications, such as agricultural uses.

### Applications of Fabric Buildings: -

**Agricultural Use**:

Storage forhay, equipment, and livestock shelters. -

**Industrial Use**:

Warehousing, manufacturing, and workshop spaces. -

**Recreational Use**:

Sports facilities, gymnasiums, and event venues. -

**Commercial Use**:

Retail spaces, showrooms, and temporary structures

for events. Overall, fabric buildings offer a versatile and efficient solution for a wide range of applications, combining

functionality with cost-effectiveness.

for events. Overall, fabric buildings offer a versatile and efficient solution for a wide range of applications, combining

functionality with cost-effectiveness.

Safety of Fabric Buildings

Fabric buildings can be safe and durable when designed and constructed properly. Here are some key aspects of their safety:

1. Structural Integrity:

* Fabric buildings are typically supported by a strong frame made of steel or aluminum, which can withstand various loads,

including wind and snow.

* The design should comply with local building codes, which consider factors such as wind speed, snow load, and seismic

activity.

2. Material Quality:

* High-quality, durable fabrics (like PVC or polyethylene) are used, which can resist tearing, UV degradation, and

weathering.

* Fabrics are often treated to be flame retardant, adding an extra layer of safety.

1. Structural Integrity:

* Fabric buildings are typically supported by a strong frame made of steel or aluminum, which can withstand various loads,

including wind and snow.

* The design should comply with local building codes, which consider factors such as wind speed, snow load, and seismic

activity.

2. Material Quality:

* High-quality, durable fabrics (like PVC or polyethylene) are used, which can resist tearing, UV degradation, and

weathering.

* Fabrics are often treated to be flame retardant, adding an extra layer of safety.

Analyzing Fabric Structures with 3D3S Software

3D3S is a specialized software tool used for the analysis and design of structures, including fabric structures. Here’s a

step-by-step guide on how to analyze fabric structures using the 3D3S software:

Step-by-Step Analysis Process

1. Model Creation:

* Define Geometry: Start by creating the 3D model of the fabric structure. This can include defining the overall shape,

dimensions, and layout of the fabric cover and structural frame.

* Input Nodes and Elements: Specify points (nodes) and connect them with elements to represent the fabric and supporting

framework. For fabric structures, this often involves tensioned membrane elements.

2. Material Properties:

* Assign Materials: Define the properties of the materials used in the structure: * Fabric Material: Enter parameters such as tensile strength, elasticity, and thermal properties.

* Frame Material: Specify the properties of the structural frame materials (e.g., steel or aluminum).

3. Load Definitions:

* Dead Loads: Input the self-weight of the fabric and the supporting framework.

* Live Loads: Include other loads that might act on the structure, such as occupancy loads or equipment.

* Environmental Loads: Apply relevant loads such as: * Snow Loads: Based on local building codes and snow accumulation data.

* Wind Loads: Consider wind speed and direction, applying appropriate coefficients based on the structure's geometry.

4. Boundary Conditions:

* Support Conditions: Define how the structure is supported. This may include fixed, pinned, or sliding supports at various

points.

* Tensioning: If applicable, specify tensioning conditions for the fabric, as tension is critical for its structural

performance.

5. Meshing:

* Finite Element Meshing: If the software requires it, generate a finite element mesh for the model. This divides the

structure into smaller elements for analysis.

* Element Types: Choose appropriate element types for fabric (e.g., membrane elements) and the supporting framework (e.g.,

beam or shell elements).

6. Set Analysis Parameters:

* Static or Dynamic Analysis: Choose the type of analysis you want to perform. Most fabric structures will undergo static

analysis, but dynamic analysis may be necessary for certain conditions (e.g., wind loading).

* Load Combinations: Set up load combinations according to relevant design codes to evaluate the worst-case scenarios.

7. Run the Analysis:

* Execute Calculation: Start the analysis process. The software will compute how the fabric structure behaves under the

applied loads and conditions.

* Monitor Progress: Check for any errors or warnings during the analysis run.

8. Results Interpretation:

* Displacement Analysis: Assess the displacement results to ensure they are within acceptable limits.

* Stress Distribution: Analyze the stress results to identify areas of high stress or potential failure points.

* Support Reactions: View the reactions at the supports to ensure they are manageable and within the design limits.

9. Optimization:

* Modify Design: If the results indicate issues (e.g., excessive deflection or stress), make design changes. This may

involve adjusting the geometry, selecting different materials, or changing the tensioning system.

* Re-run Analysis: After modifications, re-run the analysis to confirm improvements.

10. Documentation:

* Generate Reports: Compile a detailed report summarizing the analysis process, findings, and any design recommendations.

* Visual Outputs: Include visualizations such as stress contour plots, displacement diagrams, and load path diagrams to

effectively communicate results.

* Live Loads: Include other loads that might act on the structure, such as occupancy loads or equipment.

* Environmental Loads: Apply relevant loads such as: * Snow Loads: Based on local building codes and snow accumulation data.

* Wind Loads: Consider wind speed and direction, applying appropriate coefficients based on the structure's geometry.

4. Boundary Conditions:

* Support Conditions: Define how the structure is supported. This may include fixed, pinned, or sliding supports at various

points.

* Tensioning: If applicable, specify tensioning conditions for the fabric, as tension is critical for its structural

performance.

5. Meshing:

* Finite Element Meshing: If the software requires it, generate a finite element mesh for the model. This divides the

structure into smaller elements for analysis.

* Element Types: Choose appropriate element types for fabric (e.g., membrane elements) and the supporting framework (e.g.,

beam or shell elements).

6. Set Analysis Parameters:

* Static or Dynamic Analysis: Choose the type of analysis you want to perform. Most fabric structures will undergo static

analysis, but dynamic analysis may be necessary for certain conditions (e.g., wind loading).

* Load Combinations: Set up load combinations according to relevant design codes to evaluate the worst-case scenarios.

7. Run the Analysis:

* Execute Calculation: Start the analysis process. The software will compute how the fabric structure behaves under the

applied loads and conditions.

* Monitor Progress: Check for any errors or warnings during the analysis run.

8. Results Interpretation:

* Displacement Analysis: Assess the displacement results to ensure they are within acceptable limits.

* Stress Distribution: Analyze the stress results to identify areas of high stress or potential failure points.

* Support Reactions: View the reactions at the supports to ensure they are manageable and within the design limits.

9. Optimization:

* Modify Design: If the results indicate issues (e.g., excessive deflection or stress), make design changes. This may

involve adjusting the geometry, selecting different materials, or changing the tensioning system.

* Re-run Analysis: After modifications, re-run the analysis to confirm improvements.

10. Documentation:

* Generate Reports: Compile a detailed report summarizing the analysis process, findings, and any design recommendations.

* Visual Outputs: Include visualizations such as stress contour plots, displacement diagrams, and load path diagrams to

effectively communicate results.

Conclusion

Using 3D3S for fabric structure analysis provides a comprehensive approach to understanding the structural behavior under various

conditions. Proper modeling, load application, and interpretation of results are critical to ensuring safety and performance.

Hot galvanizing is a process used to protect steel from corrosion by coating it with a layer of zinc. This is achieved by

immersing the steel in molten zinc at a temperature of around 450°C (842°F). The zinc reacts with the steel to form a series of zinc-iron alloy layers, providing a durable and protective coating.

Advantages of Hot Galvanized Steel

1. Corrosion Resistance: The zinc coating provides excellent protection against rust and corrosion, extending the lifespan of steel structures, particularly in harsh environments.

2. Durability: Hot galvanized coatings are tough and resilient, able to withstand mechanical damage and environmental stressors.

3. Maintenance-Free: Once galvanized, steel components require little to no maintenance over their lifespan, reducing long-term

costs.

4. Cost-Effective: While the initial cost may be higher than untreated steel, the long-term savings from reduced maintenance and

longer service life can make hot galvanized steel more economical.

5. Environmental Protection: The process is environmentally friendly, as the zinc used is recyclable, and the coating process

does not produce harmful byproducts.

6. Adhesion: The metallurgical bond between the zinc and steel provides a strong, long-lasting coating that adheres well to the

base metal.

7. Aesthetic Appeal: Hot galvanized steel typically has a clean and attractive finish, making it suitable for visible

applications.

immersing the steel in molten zinc at a temperature of around 450°C (842°F). The zinc reacts with the steel to form a series of zinc-iron alloy layers, providing a durable and protective coating.

Advantages of Hot Galvanized Steel

1. Corrosion Resistance: The zinc coating provides excellent protection against rust and corrosion, extending the lifespan of steel structures, particularly in harsh environments.

2. Durability: Hot galvanized coatings are tough and resilient, able to withstand mechanical damage and environmental stressors.

3. Maintenance-Free: Once galvanized, steel components require little to no maintenance over their lifespan, reducing long-term

costs.

4. Cost-Effective: While the initial cost may be higher than untreated steel, the long-term savings from reduced maintenance and

longer service life can make hot galvanized steel more economical.

5. Environmental Protection: The process is environmentally friendly, as the zinc used is recyclable, and the coating process

does not produce harmful byproducts.

6. Adhesion: The metallurgical bond between the zinc and steel provides a strong, long-lasting coating that adheres well to the

base metal.

7. Aesthetic Appeal: Hot galvanized steel typically has a clean and attractive finish, making it suitable for visible

applications.

Похожие товары

Форменная хижина quonset сборные комплекты металлическая крыша

15,90-25,90 $

Большая купольная крыша из ПВХ металлическая рама промышленный контейнер для доставки укрытия навесы оборудования навес хранения палатки

Лучшая цена укрытие-контейнер-купола укрытие для контейнеров 40-футовый грузовой навес дом коз фермерский сарай

16,00-25,00 $

Кровать Солнцезащитная пляжная украшения парка детская переносная палатка топлива Hardtop стеклоткани полюс двойной кабины рабочими электрическими схемами принцессы гараж навес

Двойные вершины PE ротанга беседка железный каркас полиэфирной ткани оптовая цена

Автомобильный тент для кемпинга

55,00-65,00 $

Тяжелый навес для автомобиля 20x40 футов

229,00-259,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $