Самый сильный лазерный автоматический маленький робот кобот сварочный аппарат станция цена Роботизированный коробчатых балок

- Категория: >>>

- Поставщик: Sichuan Strongest Laser Technology Co. Ltd

Сохранить в закладки 1601253123968:

Описание и отзывы

Характеристики

Products Description

Project | Unit | STR-HW200 | STR-HW350 | STR-HW450 | STR-HW550 | |||

Laser Power | W | 700W | 900W | 1200W | 1500W | |||

Rated input power supply | - | single phase 220V | single phase 220V | single phase 220V | single phase 220V | |||

Input power frequency | Hz | 50/60 | 50/60 | 50/60 | 50/60 | |||

Rated input power | W | 3200 | 3800 | 4200 | 5400 | |||

Welding speed | cm/min | 20~200 | 20~200 | 20~200 | 20~200 | |||

Cooling mode | - | Dual-Circuit Refrigerant Direct Cooling | Dual-Circuit Refrigerant Direct Cooling | |||||

Working temperature | ℃ | -20~60 | -20~60 | -20~60 | -20~60 | |||

Working humidity | % | -30~70 | -30~70 | -30~70 | -30~70 | |||

Product dimensions | mm | 673×580×310 | 673×605×310 | 673×605×310 | 673×605×310 | |||

Product weight | kg | 38 | 43 | 43 | 45 | |||

Applicable Wire Diameter | mm | 0.8/1/1.2/1.4/1.6 | ||||||

Number of preset process packages | unit | 16 | 24 | 30 | 40 | |||

Number of customizable process packages | unit | 20 | 20 | 20 | 20 | |||

Output mode | - | Integrated armored cable+welding gun | ||||||

Welding mode | - | Spot welding/continuous spot welding/pulse welding/ continuous welding | ||||||

Applicable materials

----------------------

Suitable for welding various metals, including but not limited to aluminum, stainless steel, carbon steel, galvanized sheet, brass, etc.

Parameters Matrix for Welding with Wire Fed | ||||||||

Aluminum | Stainless Steel | Galvanized Sheet | Carbon Steel | |||||

STR-HW550 | ≤6mm | ≤6mm | ≤6mm | ≤6mm | ||||

STR-HW450 | <4mm | <4mm | <4mm | <4mm | ||||

STR-HW350 | <3mm | <3mm | <3mm | <3mm | ||||

STR-HW200 | 0.2-2.5mm | 0.2-2.5mm | 0.2-2.5mm | 0.2-2.5mm | ||||

*The above data are the maximum averaged full penetration obtained through multiple rounds of experiments.

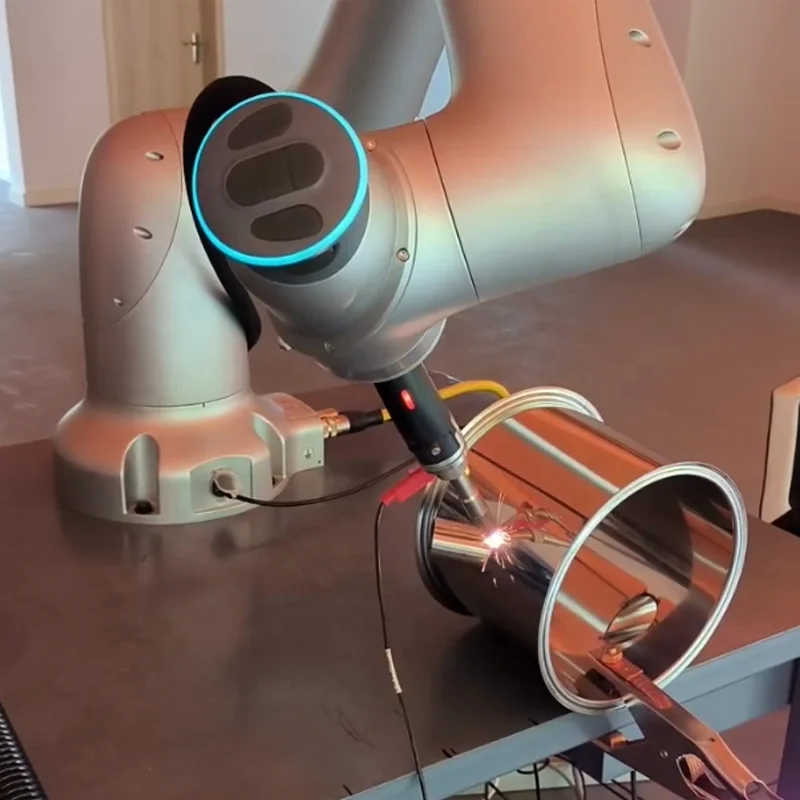

You can choose the appropriate collaborative robot independently (not limited to the brands recommended below), and we will provide you with professional customized solutions.

Specification | CR7 | CR12 | |

load | 7kg | 12kg | |

working radius | 988mm | 1434mm | |

Weight (including built-in control cabinet) | ≈27kg | ≈43kg | |

DOF | 6 | 6 | |

MTBF | >50000h | >50000h | |

Working temperature range | 0°C~50°C | 0°C~50°C | |

Typical power consumption | 300w | 500w | |

IP degree | IP54/IP67 | ||

Force control relative accuracy | 0.5N I 0.1Nm | 0.5N I 0.1Nm | |

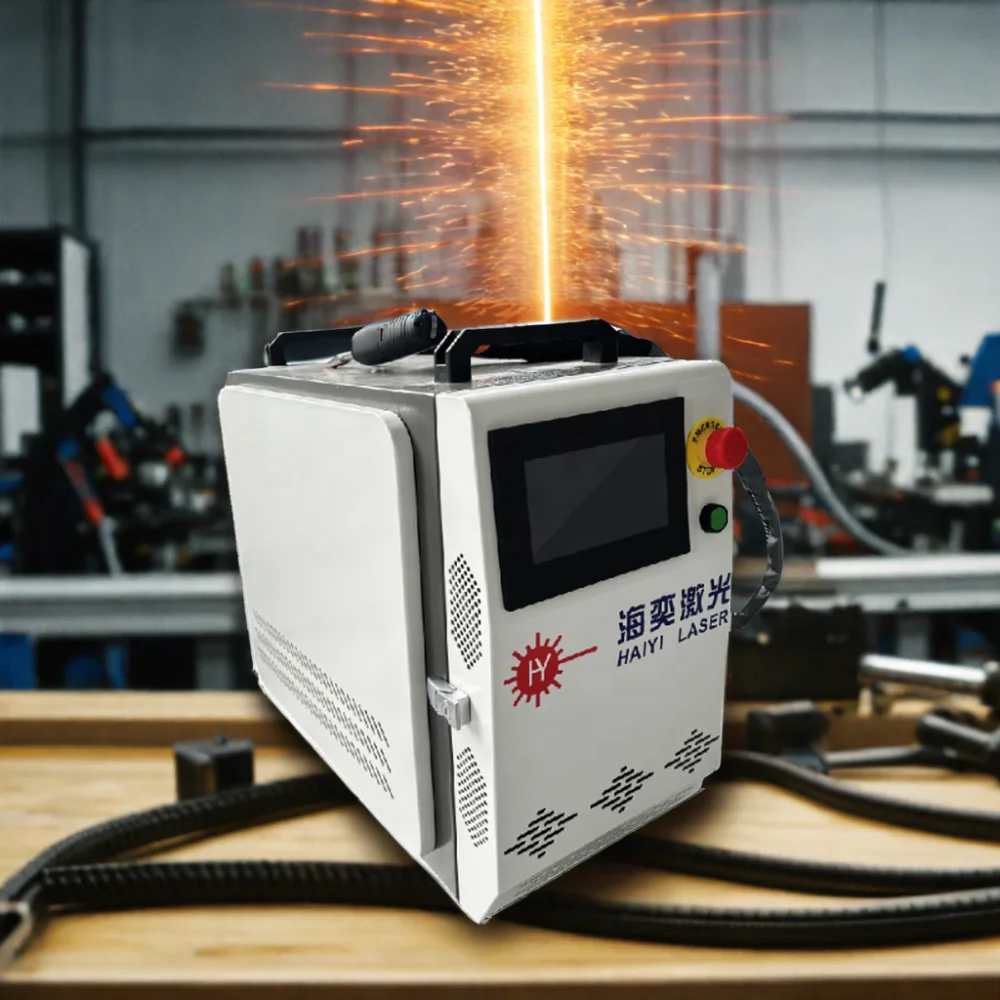

Fully-enclosed and Interface-free Integrated Design ofthe Welding Gun Eliminate the Need to Use Qbh or QcsBringing a Better Welding Experience:

Reduced energy loss, high transmission efficiency, and good welding effect;

Reduced probability of failure and extended service life;

Uninterrupted normal operation in harsh environments;

Unique shielding gas output passage that can effectively suppress splashes;

Longer fatigue-free welding owing to greatly reduced dimensions and weight,ergonomic design, comfortable grip due to a handle angle of 120°, and a wire feedingangle of 50°-60°

Unique shielding gas output passage that can effectively suppress splashes;

Longer fatigue-free welding owing to greatly reduced dimensions and weight,ergonomic design, comfortable grip due to a handle angle of 120°, and a wire feedingangle of 50°-60°

Product features

·Adapt to QBH interface.

·Dual axis spot trajectory editing with multiple swing application modes, suitable for more

Multiple welding process requirements.

·This product can increase fusion width, gap adaptability, and reduce weld defects,

Excellent forming effect significantly improves welding quality.

·The internal optical system of the product is completely sealed to prevent contamination of the optical lenses

·Protective mirror drawer design, easy to maintain, effectively extending product life

·Compact design, small size and light weight

·Dual axis spot trajectory editing with multiple swing application modes, suitable for more

Multiple welding process requirements.

·This product can increase fusion width, gap adaptability, and reduce weld defects,

Excellent forming effect significantly improves welding quality.

·The internal optical system of the product is completely sealed to prevent contamination of the optical lenses

·Protective mirror drawer design, easy to maintain, effectively extending product life

·Compact design, small size and light weight

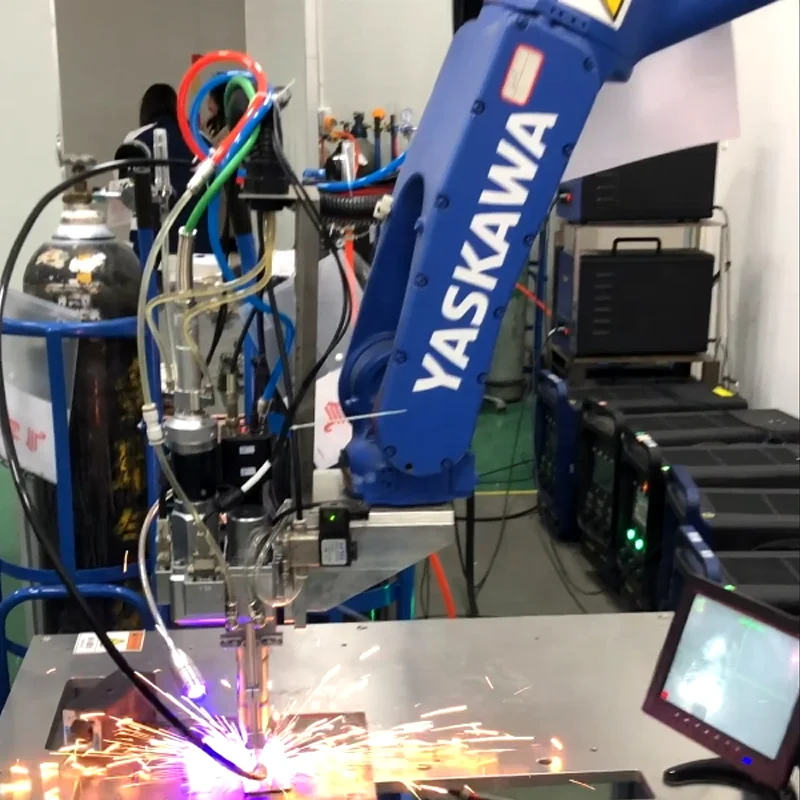

Application cases

Automobile and parts industry.

The automotive industry has strict standards and complete systems, and users focus on quality consistency for repetitive tasks, so cost-effective collaborative robots are the ideal choice. The easy installation and secondary deployment of flexible collaborative robots better meets the automotive industry's needs for customization and rapid response to the changing market. Leading safety ensures the safety of operators while improving efficiency, making coexistence and collaborative work between humans and machines a reality.

Electronic Communications: Electronic Components.

Electronic components are electronic components and components of small electrical machines and instruments. They are often composed of several parts and can be used universally in similar products; they often refer to certain parts of electrical appliances, radios, instruments and other industries, such as capacitors and transistors. , hairspring, spring and other sub-devices in general. Laser welding has the characteristics of fast welding speed, large aspect ratio, small deformation, and high density. It is a welding process that uses laser action to generate instantaneous melting on the metal surface to connect metals. It is a non-contact processing method, so no mechanical Extrusion or mechanical stress, especially in line with the processing requirements of the electronics industry.

Hardware and building materials: hardware, building materials.

It is widely used in laser welding and automation integration applications in glass fiber platinum-rhodium alloy drain plates, relays, elevator panels, washing machines, dishwashers, range hoods, microwave ovens, water cups, refrigeration valves, flat-panel solar energy and other niche areas.

COMPANY PROFILE

STR based on its core competence in high power fiber laser technologies, STR has always been committing itself to R&D and equipment production in such application fields as conventional laser welding, special laser hybrid welding and precision cutting. It is a "National High-Tech Enterprise" engaged in R&D, production, sales, and technical service.

Guided by market demand and the national strategy of supporting the development of emerging industries and industrialization, STR has strengthened the comprehensive competitiveness of its core technologies, key components, and main products, and gradually established a product system in high-end industrial applications, defense applications, and other fields.

Over the years of development, STR has provided various services to over 1000 enterprise users and professional services for over 10,000 times. Its sales network covers over 30 provinces and provincial-level municipalities in China, and its products are exported to dozens of countries including the United States and some in Europe, and Southeast Asia.

MORE +

Factory&Office Area.

We have our own factory and office area. Factory: 302, Block 11, Haolang Industrial Park, Airport Road 4, Chengdu, Sichuan; Office: 904, 9th Floor, Zone A, Building 1, No. 200 Tianfu Fifth Street, Chengdu High tech Zone, China (Sichuan) Pilot Free Trade Zone.

Technology & R&D.

The domestic first-class R&D team drives industry technological innovation.

Warehouse&Application Testing.

Including a 4000 square meter optical cleaning workshop, and equippewith a full spectrum of internationally advanced experimental instruments and equipment.

CERTIFICATIONS

Accept your suggestions and criticisms and correct them in time

Seeing your praise is our unremitting motivation.

True evaluation >>

FAQ

Q1: How to select the suitable machine? |

A1:Tell us your material, detail requirements by words, pictures or video. We will recommend you the suitable model with the reasonable price. |

Q2: How about the lead time? |

A2:For the standard machine, the delivery time is 3-7 days after the payment.For the non-standard machine, the delivery time is 7-15 days after the payment. |

Q3:How to install and use it? |

A3:We have the instruction Book, Operational manual and Training Videoinside the machine.We also can provide the training on line by free. |

Q4:How to do it if we meet the issue during the operation? |

A4:You can send the wrong information to us by mail, we can help us solveit by mail.phone, or video communication. |

Q5:Do you provide the onsite service if we needed? |

A5:Yes. We can provide the onsite service if you needed. But need the cus-tomer pay. |

Похожие товары

Ручной металлический лазерный сварочный аппарат мини-типа лазерный сварочный аппарат 800 Вт с воздушным охлаждением лазерное сварочное оборудование

Лазерная сварочная машина высокой точности резки и соединения оборудования для промышленного производства низкая цена надежная

54 003,10 ₽ - 64 803,72 ₽

Квадратный литиевый аккумулятор козловой Тип Автоматический Лазерный Сварочный аппарат силовой аккумулятор алюминиевый корпус сварочное оборудование

Небольшой лазерный сварочный аппарат с водяным охлаждением, 2000 Вт, ручное лазерное сварочное оборудование

336 979,35 ₽ - 351 020,15 ₽

Алюминиевый лазерный сварочный аппарат волоконно-лазерное оборудование для алюминиевого сварочного аппарата из нержавеющей стали ручной

421 224,18 ₽ - 437 425,11 ₽

Портативный лазерный сварочный аппарат 3 в 1, 1500 Вт

300 905,28 ₽

1500 Вт машина или лазерный сварочный аппарат 4 в 1 лазерное сварочное оборудование заводская цена

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $