Формы для совместной экструзии ПВХ

- Категория: >>>

- Поставщик: Hubei Gaoxin WPC Extrusion Co. Ltd.

Сохранить в закладки 1601253387356:

Описание и отзывы

Характеристики

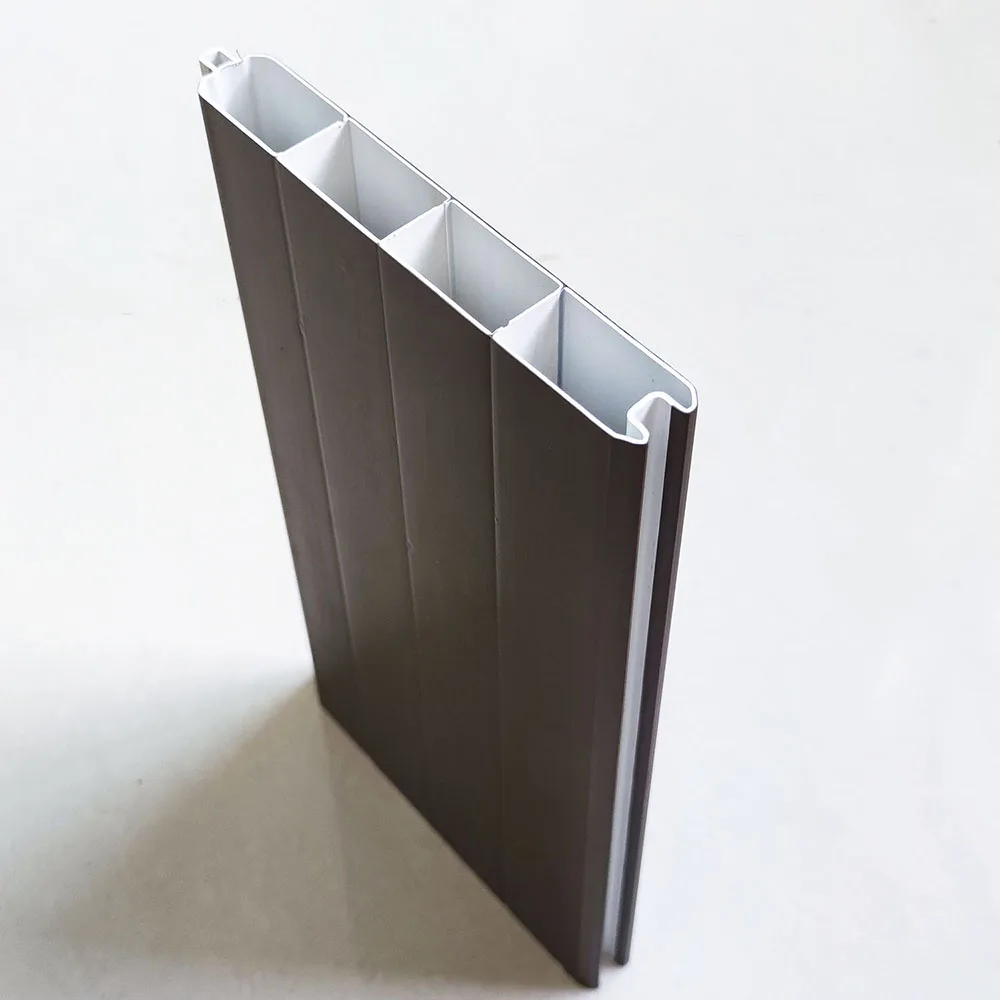

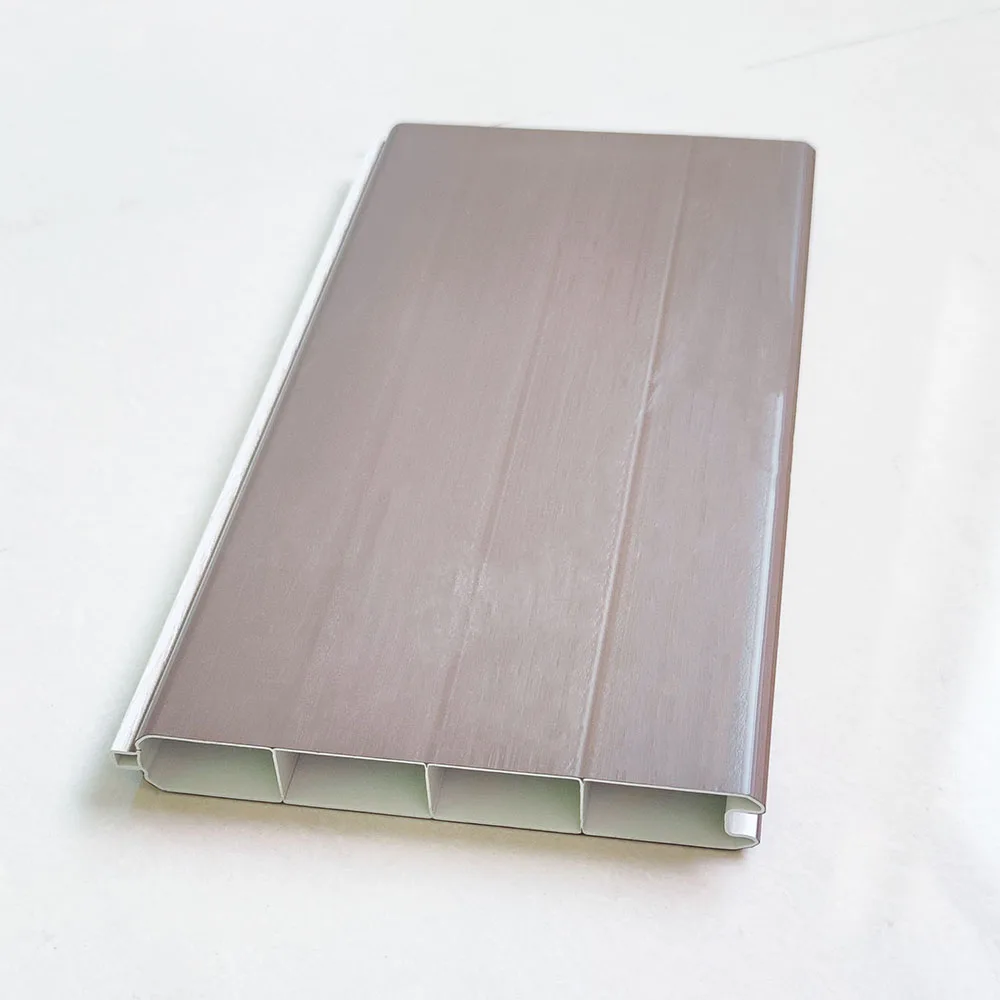

Production Introduction:PVC window extrusion tool /PVC profile extrusion machine /PVC profile production machine

description | PVC window extrusion tool /PVC profile extrusion machine /PVC profile production machine |

Size | Various Sizes as Per Customer Require |

Mould Material | 3Cr17, 3Cr17MoNiV, DIN1.2316 or Negotiable |

Mould Cavity | One or Multi-Cavity |

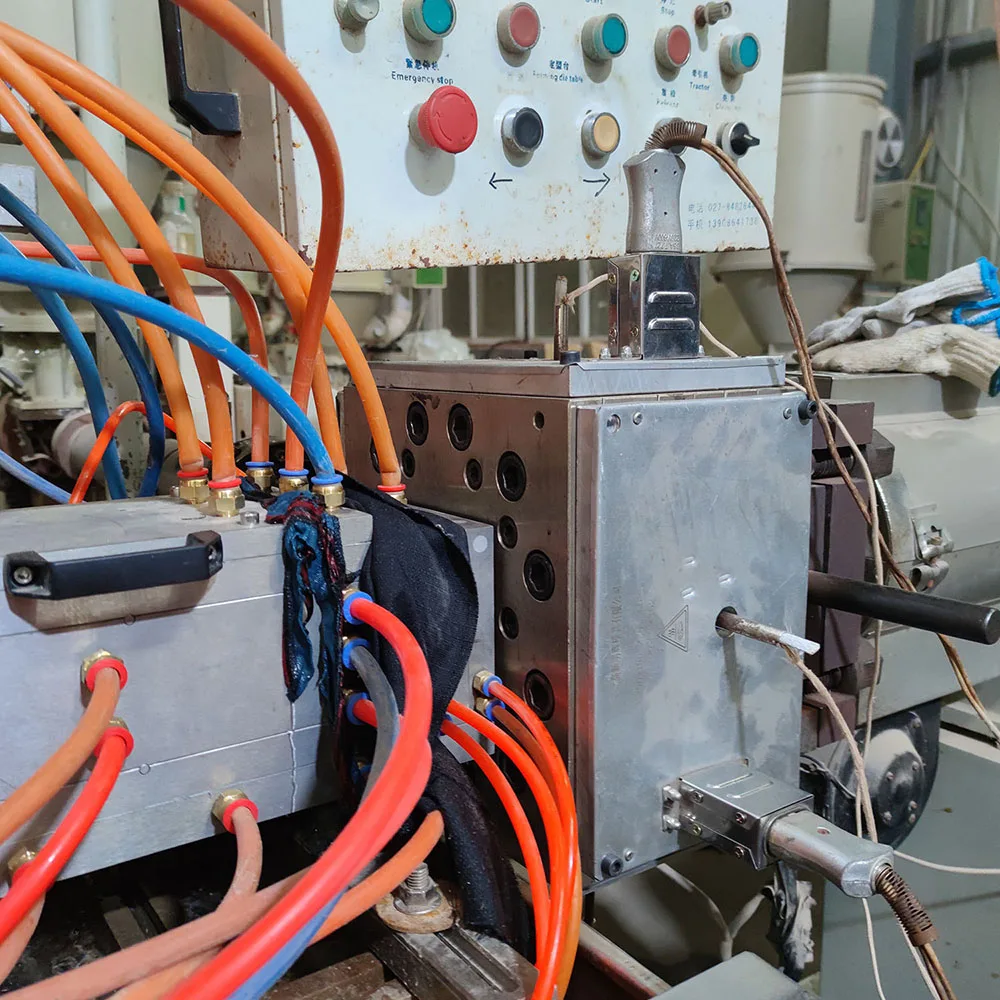

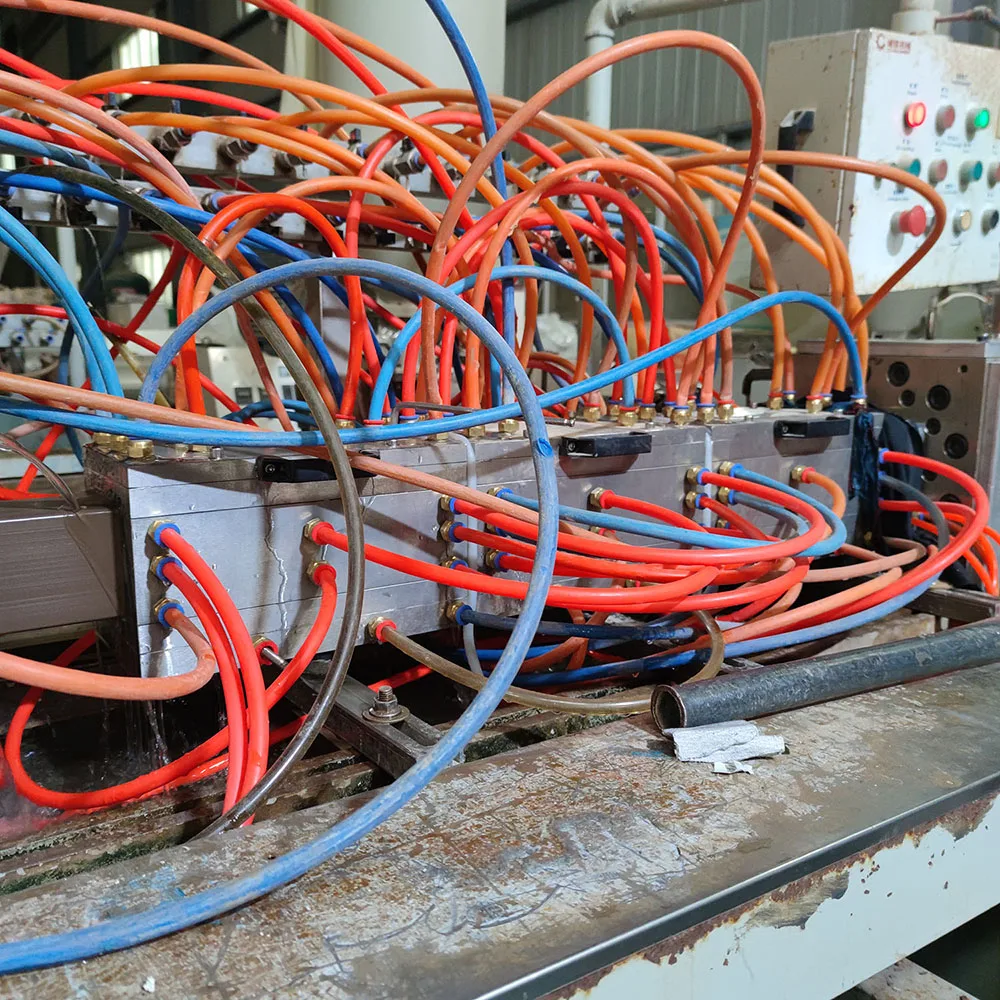

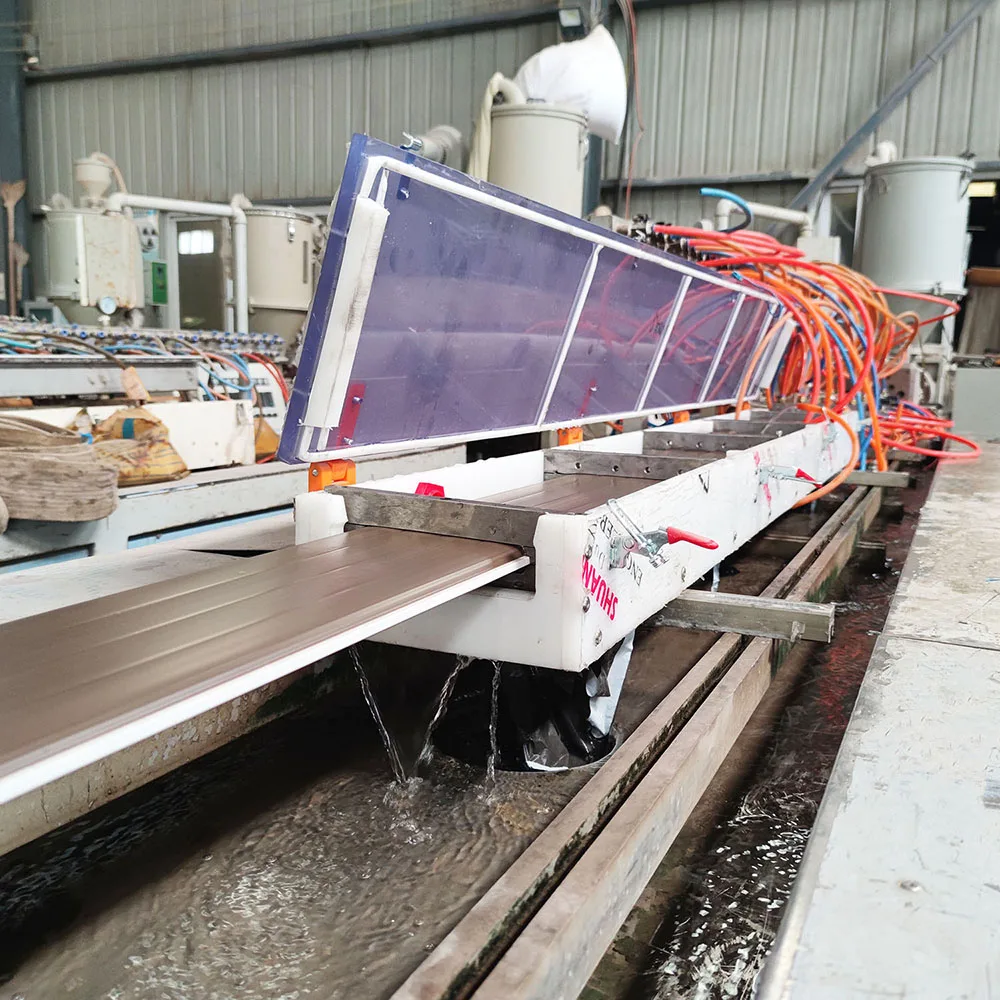

Mould Composition | Die Head, Aluminum Heating Panels, Calibrators and Water Tank |

Feature | High Polished Surface, Stable Discharging, Soft-hard, Surface Layer, Cladding |

Test | Mould will be tested to get the satisfy sample before delivery |

Sample | Sample will be arranged by express for customer approval |

Service | Provide complete set of formulation, technology and perfect after sale service |

Lead time | 30-35days |

Package & deliver | Poly wood case for exporting, each mould will be cleaned before packing. |

Remark : If you are interesting in mould and plastic prodcuts, welcome you provide us the details of the product material , size , weight ect, better 2D and 3D drawing. Welcome you to visit us. | |

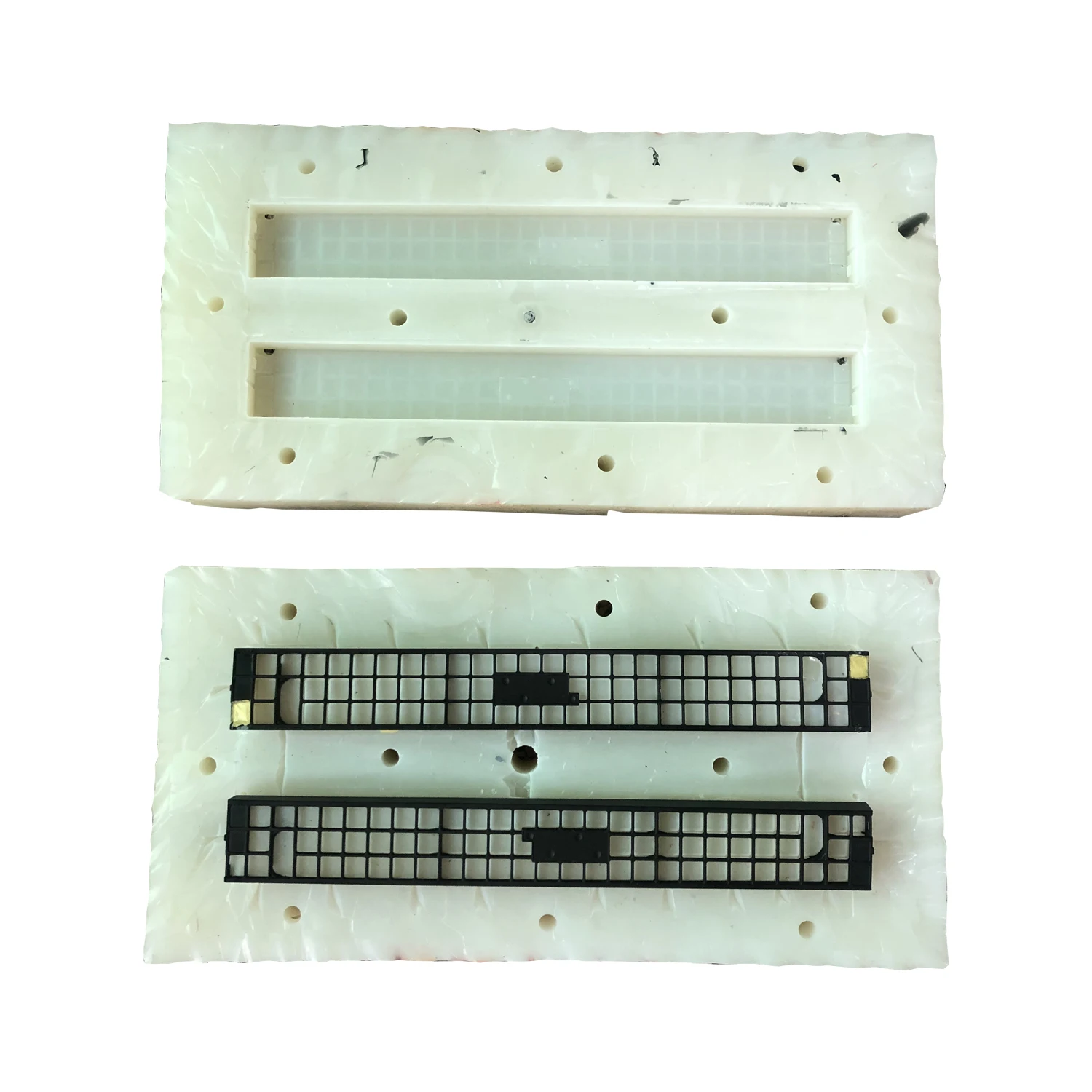

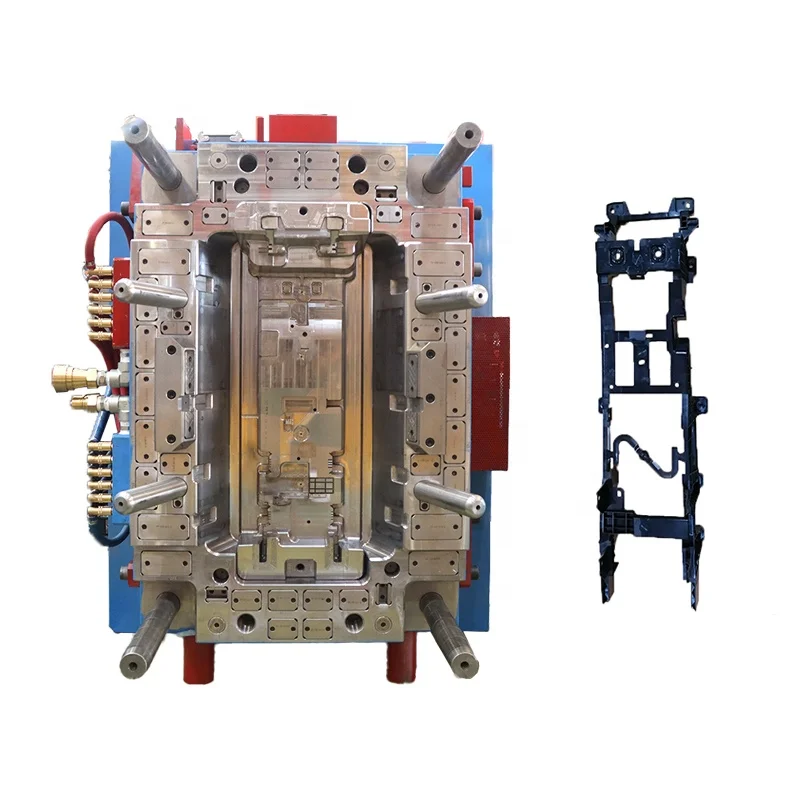

The Composition and Function of each part for WPC Extrusion Mould :

Configuration of Mould | Functions | Types |

Dies head | Produce continuous,stable,homogeneous profile | Divided into four standards based on different appearances: D1602,D1802,D2002,D3002 |

Calibrators | Cool down and form the profile, the smaller the resistance is ,the better | Divided into four standards based on different widths: C1402,C1702,C2002,C3002.The quantity of calibrator parts are decided by profile, and extrusion speed. |

Water tank | Cool down the profile further | Divided into three kinds: organic glass, stainless steel, pp board. They have wonderful tightness, brief frame, easily be processed. |

Why Choose Us:

1, We are the biggest extrusion mould for PVC and WPC profile designer and manufacturer, our PVC extrusion moulds account for the overwhelming majority domestic market.

2, We are the only one mould factory who attend the People's Republic of China National wood plastic composite flooring Standards drafting .

3, We are the Professional Committee of PVC products governing unit

4, the top 10 WPC decking factory in China have cooperation with us .

High quality of after-sale service:

- Over the past decade,we always provide customers with perfect service.

- Our technicist will test each mould before they leave the factory.

- We could give the whole support for customer in raw material formula,selection of extruder machine,mould technique and operation training on the spot.

- We also can supply top-quality moulds and resonable price depends on customers requests(pictures or CAD drawing or samples).

Похожие товары

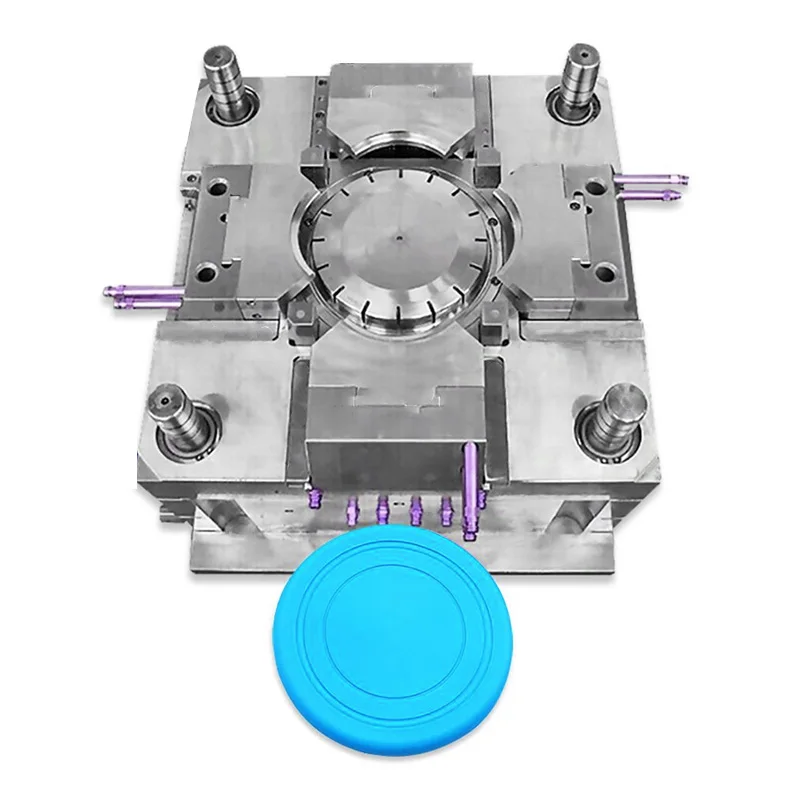

Изготовитель пластиковых форм для литья под давлением, вакуумное литье под давлением

Изготовленный на заказ силиконовый резиновый инструмент для клавиатуры производитель силиконовый OEM ODM Services кнопочный чехол для клавиатуры

Силиконовая Кнопка Крышка Водонепроницаемый Силиконовая Кнопка крышка пользовательская силиконовая клавиатура

Силиконовая резиновая форма

Изготовленные на заказ силиконовые резиновые кнопки для кнопок, крышки для бутылок, прототип, услуга, Oem, герметизирующие резиновые полимерные формы, силиконовые формы

Изготовленная на заказ пластиковая литьевая форма автомобильная консоль задний Монтажный кронштейн внутренняя внешняя отделка США автомобильная форма для инструмента

Высококачественная пресс-форма для литья пластмасс под давлением, производитель пресс-форм для литья под давлением, пресс-форма на заказ

Новые поступления

Новинки товаров от производителей по оптовым ценам