Китай профессиональное оборудование для выпечки и небольшая производственная линия хлеба машина

- Категория: >>>

- Поставщик: Henan Gondor Equipment Material Co. Ltd.Henan Ltd.

Сохранить в закладки 1601256283605:

Описание и отзывы

Характеристики

Introduction

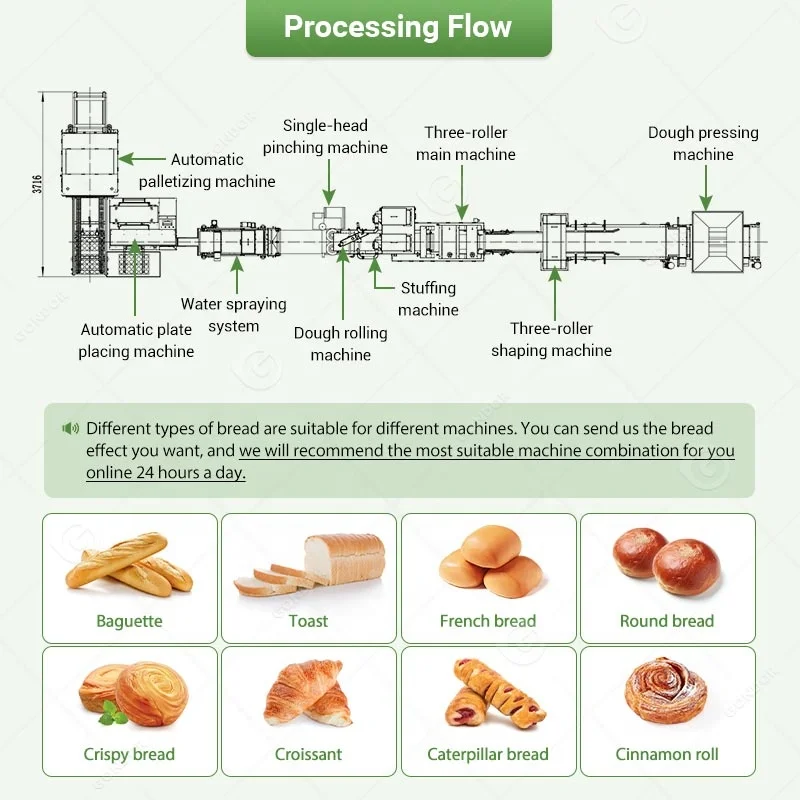

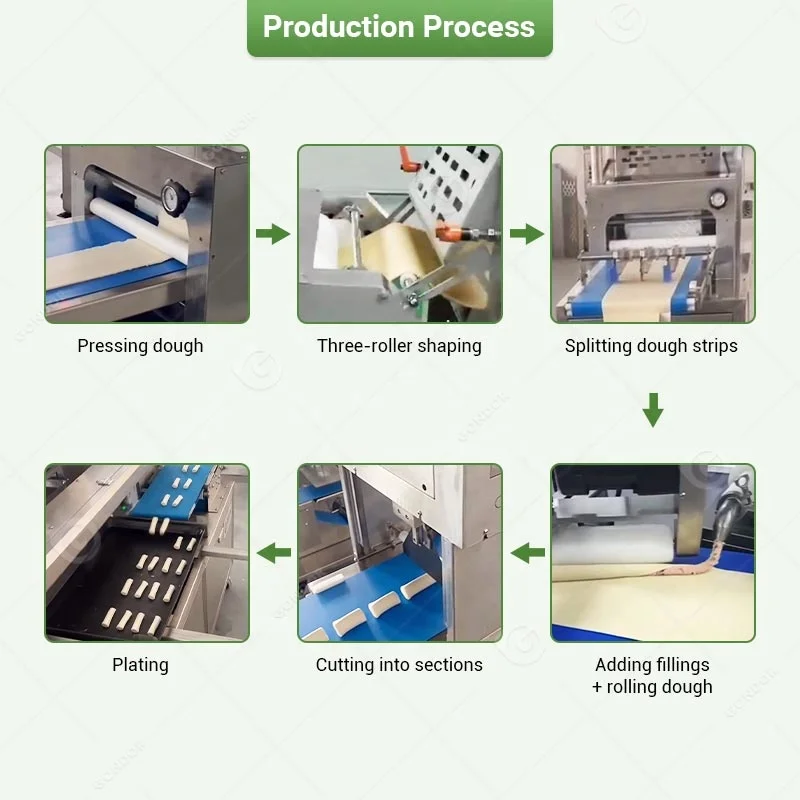

The bread production line is an automated equipment system for mass production of various types of bread. It includes multiple links such as raw material processing, dough making, fermentation, forming, baking and packaging, ensuring efficient and standardized production of high-quality bread. The main features are high production efficiency, stable quality, easy operation and versatility, suitable for bakeries, food processing plants and central kitchens. The production line can not only save labor costs, but also increase production capacity, ensuring that each batch of products is consistent and high quality.

Paramater

Product name | Product Parameters |

Fully automatic noodle pressing machine | Noodle pressing width <500mm Voltage/power: 380V/3.0kw Dimensions: 1300*1000*1400mm Weight: about 450kg |

Noodle strip splitting and shaping machine | Roller width 320mm Voltage/power: 380V/1.5kw Dimensions: 3300*700*1300mm Weight: about 100kg |

Three-pass rolling machine | Roller width 300-500mm Voltage/power 380V/3.2kw Dimensions 4100*770*1500mm Weight about 400kg |

Dough strip slitting machine | Voltage/power 380V/220V/0.2kw Dimensions 1250*920*700mm Weight about 70kg |

Dough Rolling Machine | Voltage/power 220V/0.32kw Dimensions 1750*920*940mm Weight about 90kg |

Filling machine | Diameter of feeding port: 6-38mm (customizable) Voltage/power 220V/0.75kw Dimensions 1000*410*1320mm horizontal Dimensions 500*400*1430mm vertical Weight about 90kg |

Split cutting table (servo) | Production capacity 50-180 pieces/minute Voltage/power 220V/380V/0.75kw Dimensions 1200*620*1300 Weight about 180kg |

Flower pinching machine | Production capacity 2000-6000 pieces/hour Voltage/power 220V/0.75kw Dimensions 1350*750*1200mm Weight about 180kg |

Tray machine (servo) | Production capacity 1200-12000 pieces/hour Voltage/power 220V/380V/0.76kw Dimensions 3000*1100*1300mm Weight about 180kg |

Important reminder

1 The technical parameters are for reference only.

2 The product quotation is for reference only, It is based on the actual purchased model and configuration.

3 For more information, please call or consult customer service.

Q1. What types of bread can the production line produce?

Bread production lines are typically suitable for producing a variety of bread types, including baguettes, loaves, sweet bread, Danish pastries, whole wheat bread, etc. Some production lines can be adjusted to produce different kinds of bread by configuring the equipment and parameters.

Q2. What is the production capacity of the line?

The production capacity depends on the specific model and configuration of the production line. Generally, modern bread production lines can produce several thousand to tens of thousands of loaves per hour. The exact capacity should be determined based on actual needs and equipment specifications.

Q3. How many operators are needed for the production line?

Highly automated bread production lines usually require fewer operators, generally 1-3 people to manage the entire production process. The operators' main responsibilities include monitoring the equipment, adding raw materials, and packaging the finished products.

Q4. Is the equipment easy to clean and maintain?

Most bread production lines use modular designs, making the components easy to disassemble and clean. Additionally, the production lines are equipped with automatic cleaning systems and intelligent lubrication systems, reducing the manual cleaning and maintenance workload.

Q5. How is the energy consumption of the production line?

Modern bread production lines are designed to be energy-efficient and environmentally friendly, using efficient heating and baking systems to reduce energy consumption. Some production lines also feature energy recovery systems to further reduce energy usage.

1. 24 hour communication service.

2. Fast logistics will provide you a smooth delivery service.

3. One-year warranty and lifetime technical support.

4. New design or product recommendation.

5. Attend international Fair to negotiate with customer face to face.

6. Offer official invitation if you come to China.

7. Reception service will help you book good hotel.

Похожие товары

Новая стильная профессиональная машина для производства мягких конфет с сертификатом высокой емкости

2016 современный кухонного шоколад/чипсы оборудование для резки машина цена

Полностью автоматическая машина для производства кукурузной кукурузы/линия по производству муки/оборудование измельчения муки лучшей цене

Автоматическая круглая упаковочная машина 8 дюймов торт мороженое лакировочная ко дню рождения хлеб масло для размазывания машины пекарское оборудование

4 шт. вафельница для монет

Вафельница с антипригарным покрытием

Высококачественная газовая печь для выпечки коммерческая хлеба 2018

Новые поступления

Новинки товаров от производителей по оптовым ценам