Производитель мельниц Известняковая порошковая мельница Raymond для обессеривания электростанций

- Категория: >>>

- Поставщик: Shanghai Zenith Mineral Co. Ltd.

Сохранить в закладки 1601256342496:

Описание и отзывы

Характеристики

The limestone Raymond mill is a versatile grinding equipment widely used in mineral processing, chemical, construction and other industries. As a time-tested pulverizing solution, it produces fine and ultra-fine powders through efficient frictional grinding and classification.

Ways of Packing:

1.Sand blasting, coat with high quality paint;

2.Product wrap by PP-Bubble

3.Load container, Spear Parts in wooden case.

Transportation:

1. By sea Freight;

2. MSK/MSC/APL/EMC/WANHAI/KLINE

3. We will remind you before boat arrival

A VARIETY OF TRUSTED EXPERIENCE ZENITH has a variety of professional, reliable and efficient crushing lines all around the world. So customers have great confidence in us. |

INFINITE BRAND VALUE What ZENITH is doing is customizing economical and suitable production lines for customers and building brand value. |

1200,000 SQUARE METERS OF PRODUCITION AREA 6 large-scale manufacturing bases occupy 1200,000 square meters in total. So quick delivery is a matter of course. |

Founded in 1987, ZENITH has attained 124 patents on crushers and grinding mills over the past 30 years and has more than 30 overseas offices or branches built all over the world. Keeping customers in mind, ZENITH never stops the step forward. Wemake evolution on the outside in order to offer you better equipment; we make revolution on the inside in order to offer you better service.

Zenith Factory

Headquarter of Zenith is located in Shanghai, China and now we have two manufacturing bases as our strong support. One is located in Shanghai about 450,000 square meters, and the other is in Qidong city, about 600,000 square meters. It takes about one-hour driving from Shanghai to Qidong city.

Pre-sales Service:

To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, etc.

After-sales Service:

More than 200 engineers for after-sales service,preparing to install and debug the machines at your sites.

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers’ plants. Necessary training about machine daily maintenance to local workers is provided also.

Похожие товары

Кремнезем волластонит Микропорошок графит гидроксид магния сульфат бария Хорошего Качества Молотковая дробилка для шахтной мельницы

Зеленый LM-Y для защиты окружающей среды предварительно шлифовальный станок помогает предприятиям достичь зеленого производства

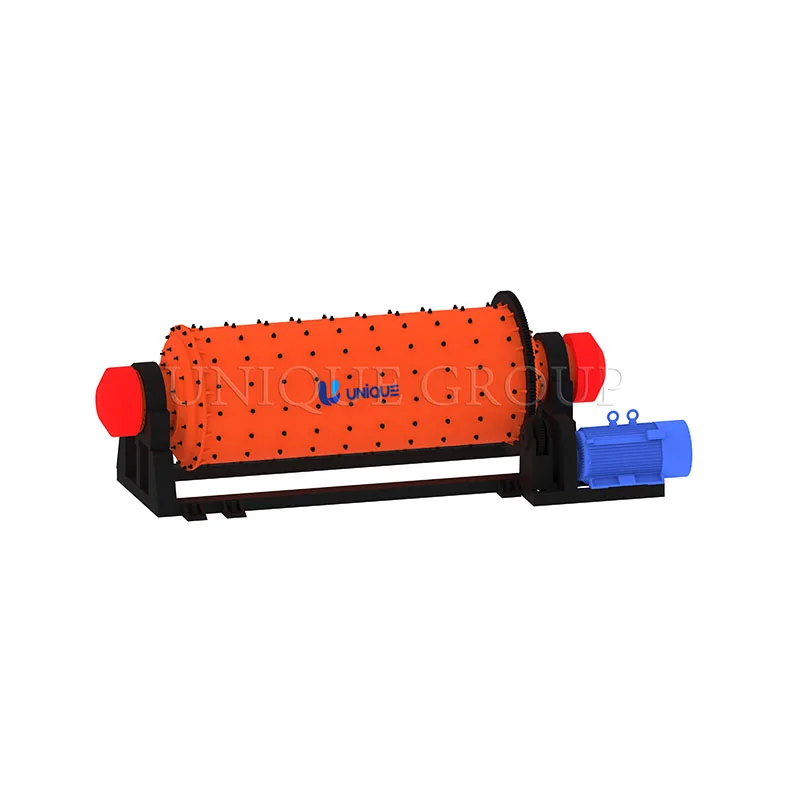

Новая шаровая мельница для добычи золотого рудного камня

Влажная сухая лабораторная цилиндрическая шаровая мельница Лабораторная фрезерная машина мелкая 50-350 кг/ч

Мясорубка из марганцевого шлака

400*600 лабораторный цилиндр небольшая шаровая мельница для шлифования образцов

Китай хорошее качество минеральной руды шлифовальный вращающийся цилиндр шаровая мельница для порошка

Новые поступления

Новинки товаров от производителей по оптовым ценам