Полистирольная машина EPS расширяющая система в стеновой панели производственная линия сэндвич полый сердечник плита установка

- Категория: >>>

- Поставщик: Guangxi Hongfa Heavy Machinery Co. Ltd.Guangxi Ltd.

Сохранить в закладки 1601257236251:

Описание и отзывы

Характеристики

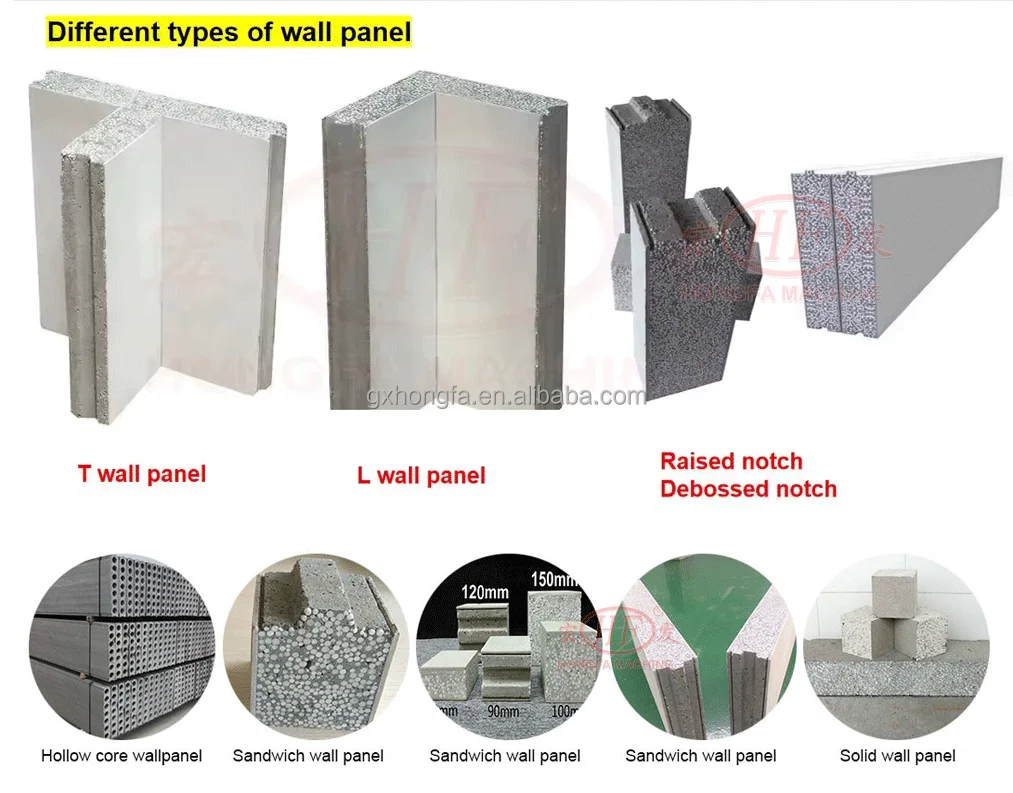

What is plastic EPS sandwich panels board

FPB lightweight partition wall panel is also known as FPB lightweight composite sandwich wall panel (calcium silicate board polystyrene particle composite sandwich wall panel): it belongs to a new generation of building partition wall panels with two layers of calcium silicate panels on the surface. It is a solid wallboard compounded with EPS polystyrene particles and various additives in the middle.

The new wall material has the characteristics of light weight, heat insulation, sound insulation, heat preservation, no formaldehyde, no benzene, and no pollution. Some materials even achieve the function of fire protection. The development of new wall materials has a huge impact on building technology and may change the form or structure of buildings. New wall materials include new raw materials and products, as well as new products of original materials. The new wall material has excellent characteristics such as light weight, high strength, heat preservation, energy saving, soil saving and decoration. The use of new wall materials not only greatly improves the function of the house, but also makes the inside and outside of the building more modern and meets people's aesthetic requirements; some new wall materials can significantly reduce the weight of the building, creating conditions for the promotion of light building structures , to promote the modernization of building construction technology, greatly speed up the speed of building. It can be seen that the new wall materials have created good economic, social and environmental benefits, and have received strong support from national policies. Therefore, the new wall materials have been recognized and favored by the society.

Advantage of the plastic EPS sandwich panels board

A:Light weight

B:Excellent sound insulation

C:Heat Insulation

D:Waterproof Fire proof

E:Energy Efficient Environmental

F:Convenient construction

G:High Intensity without deformation.

EPS concrete lightweight wall panel applications

This kind of polystyrene cement core sandwich wall panel is now dominating the construction industry as the main wall construction materials in almost all aspects of the field, such as: modern shopping mall, office, commercial center, school, hospital, factory, residential building, villa and so on, it can be not only applied to use for small projects, such as private house building, but also widely used to large scale projects, like high rise buildings and modern commercial center.

Advantages of polystyrene concrete as a material

Patented production technology and unique composition ensure excellent performance characteristics of expanded polystyrene:

excellent load-bearing capacity;

low price per cube with ease and high speed of installation of products;

increased moisture resistance;

rot resistance;

low flammability;

high heat and sound insulation;

frost resistance (at least 200 defrosting and freezing cycles);

service life - more than 100 years.

Hongfa supply complete solution of the production line equipment . board making machinery / concrete wall panels / concrete wall machine /precast concrete wall panel machine /sandwich panel machines/ precast concrete machine /eps panel making machine

Advantage of the Hongfa plastic EPS sandwich panels board

1. Install fiber cement board and aluminium molds quickly. 2-3 labors can finish 1 set of molding car(30 pcs 100mm thickness panel)within 15mins.

2. 8 hydraulic cylinder guarantee dividers keep tightly when curing. Cement hydration reaction(curing) will expand inside of the machine, so machine's design is important for panels flat surface.

3. Demolding is fast and it will not affect molds installation efficiency.

4. Verified efficiency: 7 labors can get 900sqm per 8 hours.(130sqm/labor/shift)

5. Patent protected product

6. Labor-saving and Advanced Technology

7. Double side opening and higher capacity

8. ISO9001-2015

9.Adopts touch screen control, automatic filling, electronic weighing, temperature control, material level control to realize automatic production.

10. Easy to maintainence, Easy to clean.

| Specifications | ||||||

| Production capacity of one mold cars EPS Cement panel plant as per thickness and size of the panels. Model HFP530A | ||||||

| According to length X width:2440*610mm/2270*610/3000*610mm | ||||||

| Thickness | Pieces/mold car | m2/mold car | Mold car Qty | m2/day | m2/year (300days) | |

| 60mm | 40 | 59.5 | 1 | 59.5 | 17,850 | |

| 75mm | 36 | 53.5 | 1 | 53.5 | 16,050 | |

| 90mm | 32 | 47.6 | 1 | 47.6 | 14,280 | |

| 100mm | 30 | 44.6 | 1 | 44.6 | 13,380 | |

| 120mm | 26 | 38.6 | 1 | 38.6 | 11,580 | |

| 150mm | 22 | 32.7 | 1 | 32.7 | 9,810 | |

| Charging Volume | 5m3 | |||||

| finished wall panel dimension | 2440*610*60/75/90/100/120/150mm | |||||

| hydraulic unit motor power | 2.2-5.5kw /mold car | |||||

| Size of machine | 3380*3200*2680mm | |||||

| installed capacity | 65-80kw | |||||

cement foam building EPS cement foam prefab building prefab sandwich panel machine wall panel machine concrete foam concrete wall panel machine prefabricated concrete wall hollow core slab machine lightweight aggregate EPS cement

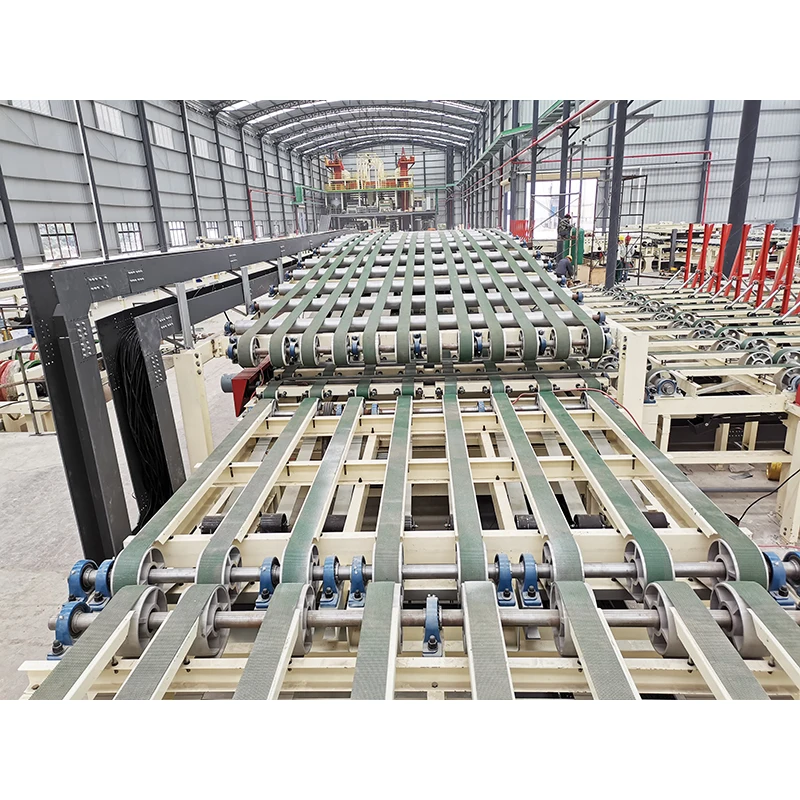

Other Main Machines for Complete Production Line

1. Mixing plant

HONGFA mixing plant consists of mixer, movable infusion unit and aggregating system. It can mix all raw material automatically and record every data for production. 3.6CBM capacity mixer guarantees infusion efficiency. It only needs about 15seconds to finish a panel with size 2440*610*100mm.

2. EPS Expander

EPS expander is used for expanding raw polysterene, one-time expander can make EPS around 15-18kg/CBM, interval expander can get proportion on 9-11kg/CBM.

3. De-molding machine

De-molding machine can pull the cured panels out deirectly, Hongfa design it based on 6 years panel manufacturing experience, make it possible that demolding machine is movable, after demolding, the molds can be installed immediately without any delay.

Multiwork is possible so efficiency is triple compared to traditional vertical manual and semi horizontal production line.

4. Recycling unit

Recycling unit can save eveything in production, waste slurry settling in underground mixer, the cement and sand will be pumped into mixer again for next mixing cycle. Keep production clean and make waste recycling, cost saving.

5. Hollow core panels unit

If you want hollow core wall panels with thickness above 150mm, HONGFA offers complete system solution. Hollow panels usually use for roof, cladding etc. purpose without any bearing demand.

6. Movable slurry piston pump unit

This unit uses for movable hydraulic slurry infusion, after mixing all raw material in mixer, then slurry pours into this movable container, it can mix and inject at same time, guarantee slurry not falling down or the heavier material(sand or cement) seperates from lighter(EPS) one.

polystyrene machine EPS expanding system in the wall panel production line sandwich panel hollow core slab machine plant

We have many succeed production line inside and outside the country of China , Such as ..............

Hongfa also support concrete panels making machine tilting table for precast concrete panel wall making, prefab house battery molds , fence wall making machine with decoration stone design, reinforced panel wall production line, precast concrete products production line . Call Jiffy or send Whatsapp 0086 18260911699 .

packing and delivery

Guangxi Hongfa Heavy Machinery Group was established in 1990, is one of the largest block making manufacturer and leading supplier of the building block industry in China,as an ISO9001-2000 certificate/CE .

RFQ

Q: What is the MOQ?

A: 5 sets.According to economic benefit analysis

Q: Can I mix different designs?

A: Sure!

Q: Can I get a lower price if I order large quantities?

A: Yes, cheaper prices with more bigger size orders.

Q: Can I add or delete items from my order if I change my mind?

A: Yes, but you need to tell us asap. If your order has been done in our production line, we cannot change

Q: When you ship my order?

A: Normally 30-45days after receiving your payment, but it can be negotiated based on order qty and production schedule.

Q: How about the quality guarantee period?

A: 5 years.

Q: How can you guarantee the production quality?

A: Our production quality follow China construction machinery standard JGJ33-2012. We have 29 years experience on producing the machines and will be inspected by QC team for ach shipment. We have strictly quality control system in our production process. We have 4 times inspection for each finished product before package Third part inspection accepxable.

1.concrete block making machine

2.EPS lightweight panel production line

3.AAC block production line

4.concrete batching production line

5.colorful roof tile /terrazzo tile / artificial stone machine

6.concrete pipe production line

7.artificial quartz slab production line

8.environmental protection equipment

9. Power station equipment

10. Mining equipment

11. Cement making equipment

12.fiber cement board/ calcium silicate board production line

13. Quicklime kiln production line

14. Terrazzo stone Inorganic terrazzo production line

15. prefab house precast concrete wall panel production line

Please not hesitate to contact us if you are interested in any kinds of products.

Contact Information:

Foreign Trade Dept. :Jiffy

Guangxi Hongfa Heavy Machinery Co.,Ltd.

Wesite://www.gxhongfa.cn

Tel:0086-18260911699 whatsapp

Fax: 0086-771-6036901

Factory add: Linyi city, Shandong province & Nanning city, Guangxi Province, China

Похожие товары

Машина для производства гипсокартона

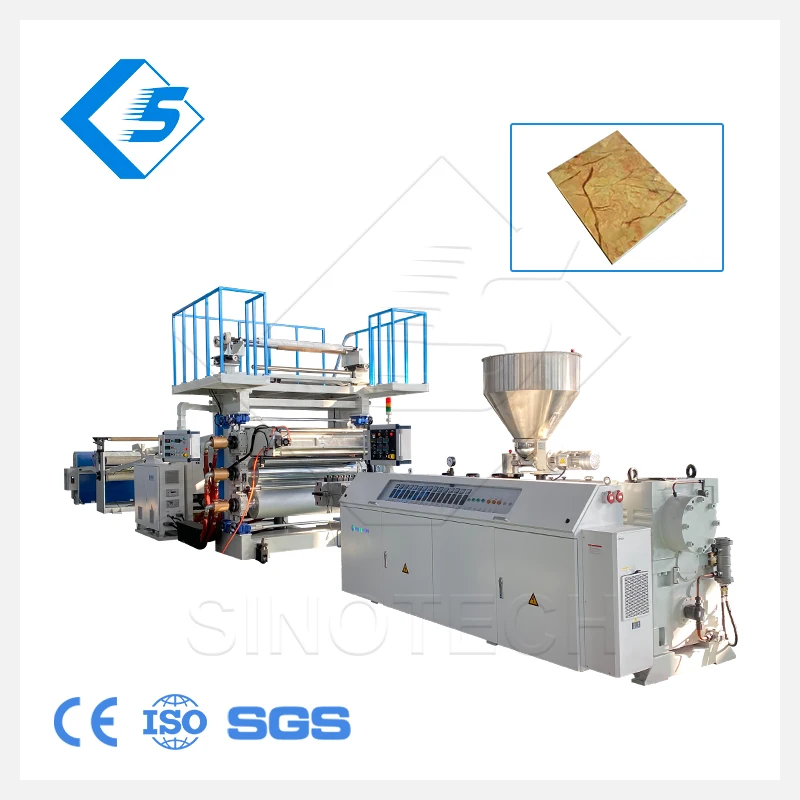

Искусственный ПВХ мраморный лист машина/пластиковая мраморная доска производственная линия/пластиковая экструдер для продажи

Машина для производства плит

ПРЕССОВАННОЕ оборудование для производства бетонных ограждений/Производственная линия

Машина для производства гипсокартона

Высококачественная легкая сэндвич-стеновая EPS-панель для производства оборудования линия по производству сборного бетона непосредственно Строительная новая

Оборудование для производства каменной ваты изоляционная плита каменных шерстяных пластин

Новые поступления

Новинки товаров от производителей по оптовым ценам