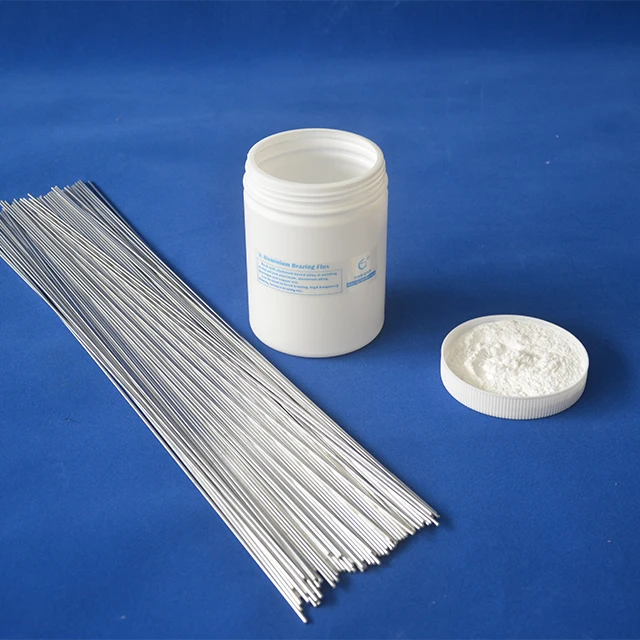

Высокотемпературный порошок AL flux

- Категория: >>>

- Поставщик: Yantai Tibright Welding Materials Co. Ltd.Yantai Ltd.

Сохранить в закладки 1601257355302:

Описание и отзывы

Характеристики

Aluminum Brazing Flux Powder

Product Usage | Aluminum brazing flux powder/paste can work together with aluminum or zinc based brazing filler metals on aluminum, aluminum alloy, copper alloy at the temperature range of 450-600°C in frame brazing, induction brazing, electrical resistance welding, furnace brazing, and so on. |

Physical Description | White powder/paste, granularity ≤ 150um. |

Standard | JB/T6045-2015 Fluxes for Brazing, Shao Sun |

Storage | Keep it in dry and cool place. Protect against damp, inedible. |

Package | a) 226.8g (8 Oz)/Plastic Can, 30 Cans/ Carton b) 454 g (16 Oz)/Plastic Can, 20 Cans / Carton c) 500 g / Plastic Can, 20 Cans / Carton d) 500 g / Plastic Bag, 60 Bags / Drum e) Customized Package is available. |

Code | Activity range(°C) | Description |

FB201S-11 | 450-660 | Good fluidity,strong ability in removing oxidation film.Can be mixed with water to become paste,with good viscosity. Water soluble, no residual left. Recommend for repairement market. |

FB201S-21 | 500-600 | Good fluidity,strong ability in removing oxidation film.Can be mixed with water to become paste,with good viscosity. Water soluble, no residual left. Recommend for radiator brazing. |

FB205S | 450-600 | Best activity for brazing with AlSi12, 4047 filler metal for the best brazing quality the requirements. Water soluble, no residule left. Highly recommend for radiator, bike producer. |

FB206S/C | 450-600 | Great activity with AlSi12, 4047 filler metal alloy. water soluble, no residule left. Highly recommend for situation of high requirements in powder or paste form. |

FB501S | 560-600 | Superior ability in removing oxidation film. Potassium floroaluminate flux system. Non-water-soluble. Thin residual film remain. Recommend for auto-radiator furnace brazing procedure. |

FB502S | 430-600 | Superior ability in removing oxidation film. Low melting temperature, water washable. Expensive materials with cesium. Recommend for auto-radiator furnace brazing procedure. |

FB503S/C | 520-600 | Great activity, low temperature, non-water soluble, thin residual film remain, in powder or paste form. |

FB504S/C | 560-600 | Self flux and no filler metal is needed. Non-water soluble, thin residual film remain, in powder or paste form. |

Yantai TiBright Welding Materials Co. Ltd., founded in 2000, is a professional developer and international supplier of inclusive brazing materials, equipment, and consultant. TiBright has hundreds of products for different applications. Customized products are also available for specific purposes.

When choose from our product library, please check out our recommended product list, If you have any questions, please let us know, We will try our best to satisfy your inquiry. Sometimes we need our customers to try different samples to make the perfect decision. Generally, we need to know the following information to choose a right product for you.

1. Materials of your parenting parts (to-be-brazed parts).

2. Heating methods. (eg. flame, induction, vacuum furnace etc. )

3. Atmosphere of application. (eg. room air, protective inert gas, reductive gas, vacuum, etc.)

4. Dimensions of your parts. Photos or graphs are preferred. (Different dimensions require different procedures.)

5. Current solution. (eg. brazing materials, equipment, procedures, etc.)

6. The reasons of searching new solution. (eg. price, strength, applicability, etc.)

7. Industry of your application. (Help us refer to similar examples.)

Похожие товары

Порошок ферросиликона железа кремния для металлургического литья сварочных электродных флюсов

D2G068 алюминиевый порошок из сплава для пайки флюса кухонной посуды серый и белый

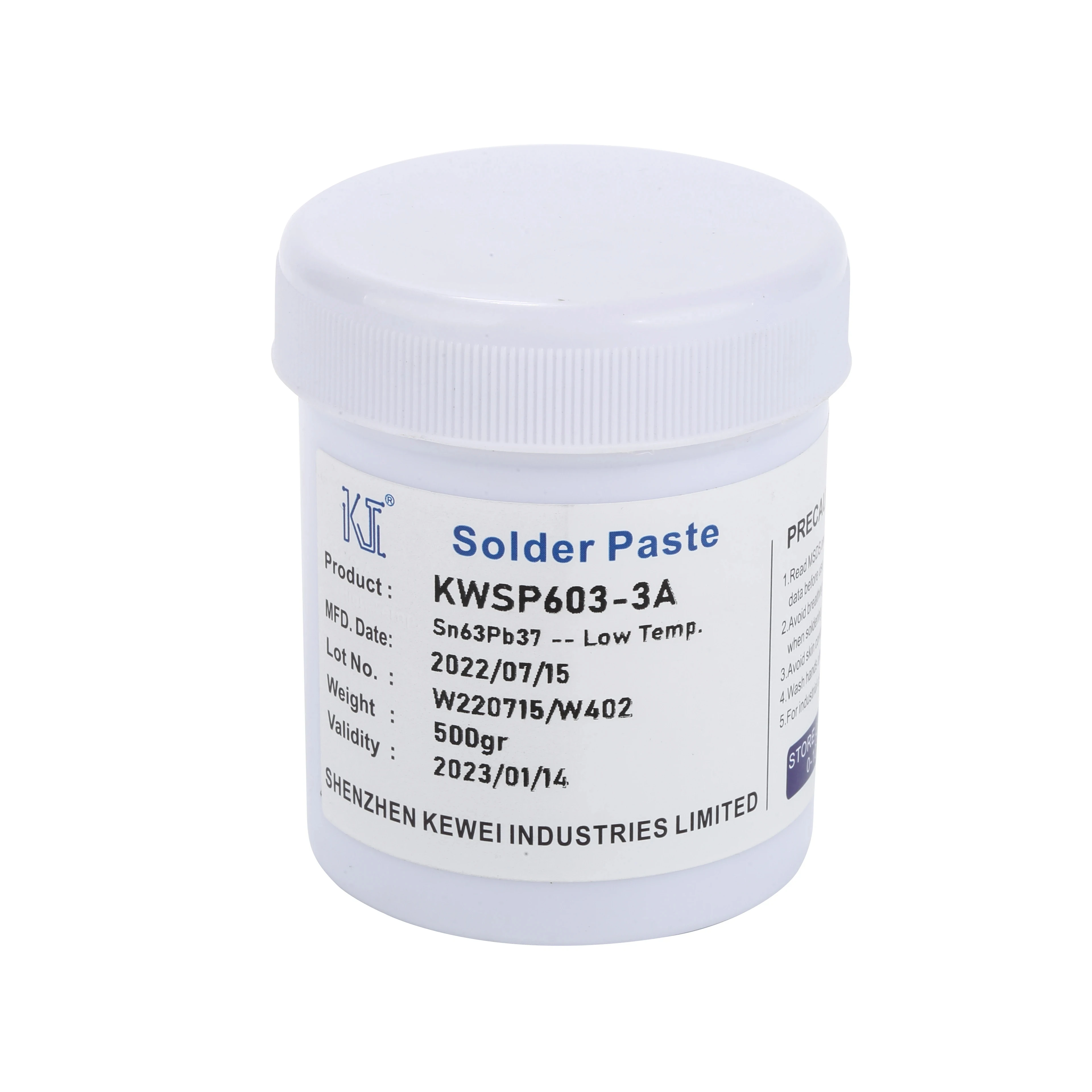

Паяльный порошок 63/37 типа 3 4 5 сплав серый для паяльной пасты кг

Алюминиевый процесс сварки горячего термита

Оловянная свинцовая паста Kewei Sn60Pb40 T3 T4 T5 500 г бутылка для печатных плат

ALY Баба Exothermic thermit сварочный поток припой порошок

Exothermic thermit сварочный поток припой порошок

Новые поступления

Новинки товаров от производителей по оптовым ценам