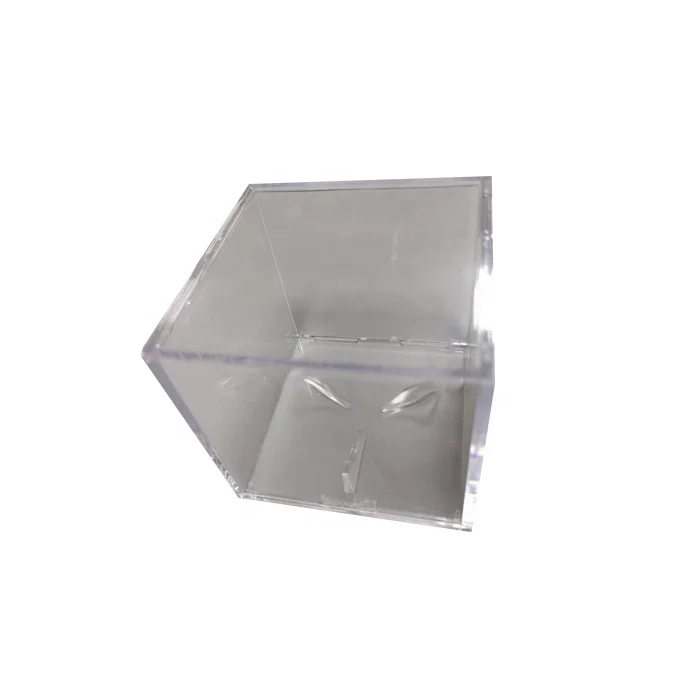

Пластиковые литьевые детали для литья под давлением на заказ пластиковые формы электронного бытового пластикового корпуса

- Категория: >>>

- Поставщик: Epposun Mold Technology (shenzhen) LtdEpposun Ltd

Сохранить в закладки 1601257400929:

Описание и отзывы

Характеристики

15 Years manufacturer specilizing in making the injeciton molds and injection molding parts.

EPPOSUN equipped with 48 Plastic injection machines including 2 sets 260T dual-color injection machines, 15 sets injection machines in clean room, 4 sets 1200T injection machines to meet different demands from worldwide customers.

EPPOSUN offers a complete spectrum of services, from mold design and simulation to mass production, surface treatment, custom packaging, and final assembly, ensuring a smooth process. Our 24/7 quoting system ensures prompt delivery within 15 to 20 days and rigorous product inspection according to customers' specifications.

Mold information:

| Mold Steel | ASSAB(Sweden) 718H, 718S, S136, S136H, 8407… |

| DAIDO(Japan) NAK80, NAK55, PX88, DC11, DC55… | |

| FINKL(America) P20, P21H, 420, P20HH… | |

| Schmiede werke Gröditz(Germany) 1.1780, 1.2344ESR, 1.3343, 1.2363, 1.2311… | |

| USINOR(France) CLC2083, CLC2316H… | |

| THYSSEN(Germany) GS711, GS738, GSP20M, GS343… | |

| LKM(China) LKM638, LKM2311, LKM738, LKM2344ESR… | |

| Mold Base | DME, HASCO, FUTABA, EMP, LKM… |

| Mold Tolerance | ±0.01mm |

| Hot Runner | DME, HASCO, MOULD MASTER, SYNVENTIVE, YUDO, INCOE… |

| Standard Parts | DME, HASCO, LKM, HEB, STRACK, OPITZ… |

| Texture | VDI 3400, Mold-tech, Yick Sang, Tanazawa etc… |

| Plastic Material | DUPONT, BAYER, BASF, SUMSUNG, CHIMEI… |

| Software | Unigraphics, SolidWorks, Pro/ENGINEER, AutoCAD, Creo, MoldFlow, CATIA… |

Q1: What services does EPPOSUN offer?

A: EPPOSUN specializes in mold design and manufacturing, plastic injection molding, metal stamping, die casting, CNC machining, and product assembly. We also provide packaging services to meet various production needs.

Q2: What certifications or qualifications does your company hold?

A: We are certified with ISO, ROHS, BSCI, and hold product patents, ensuring compliance with international quality and environmental standards.

Q3: What types of CAD files are compatible with your engineering team?

A: Our team works with a variety of file formats, including STEP, STP, IGS, STL, and X-T.

Q4: What is the accuracy of products machined based on customer drawings?

A: We maintain a high level of precision, with tolerances of ±0.02mm for molds and ±0.02mm for finished products.

Q5: How long does it take to produce an injection mold?

A: Typically, mold production takes 2-4 weeks, depending on the complexity and cavity number. Mass production lead times range from 10 to 30 business days.

Q6: What are the benefits of outsourcing manufacturing to EPPOSUN, and do you provide engineering support?

A: Outsourcing to EPPOSUN helps reduce operational costs and improves delivery times. Our engineers offer design assessments and optimization through Design for Manufacturing (DFM) to minimize costs and accelerate time to market.

Q7: How does EPPOSUN ensure quality?

A: We have an independent quality control department overseeing each stage of production through IQC, IPQC, and OQC processes. In the event of defects, we take corrective measures and, if necessary, provide returns or replacements at our expense.

Q8: How do you protect customer files?

A: We maintain strict confidentiality protocols, storing all files securely within our ERP system. We never share customer documents with third parties and are willing to sign NDAs that comply with local laws to ensure maximum security.

Q9: Can surface treatments be applied to injection-molded products, and what options are available?

A: Yes, we offer a wide range of surface treatments, including spray painting, screen and pad printing, UV coating, laser engraving, water transferring, and plating.

Похожие товары

Пластиковая форма для литья под давлением

Высококачественная Полностью прозрачная поликарбонатная лампа из поликарбоната пластиковая деталь для литья под давлением со вставной втулкой

Пластиковые детали пластиковый корпус под заказ ABS пластиковая оболочка

Пластиковые детали изготовлены из АБС ПП POM ПК нейлона и т. Д. различных материалов

Настраиваемый сборочный Пластиковый корпус для электронных устройств литья под давлением ABS PP PE корпуса

Пластиковый Чехол для мобильных телефонов

Пластиковые литьевые формы для сотового телефона

Новые поступления

Новинки товаров от производителей по оптовым ценам