KA H10 сварочный аппарат для труб прочный автоматический качественный стальных

- Категория: >>>

- Поставщик: Qingdao Yuehongbo Welding And Cutting Equipment Co. Ltd.

Сохранить в закладки 1601258008857:

Описание и отзывы

Характеристики

KA-H10

CO2 welding automatic trolleys are widely used in ships, bridges, locomotives, steel structures, petrochemicals and other industries. They are suitable for welding a variety of welding structures, such as: welding of stiffened plates, ribs, intersections, welding of box beams, etc. wait.

Its main advantages are:

1.Reduce labor intensity and improve the working environment.

2.Improve work efficiency, which is 1.5 times that of manual welding.

3.Avoid poor weld quality caused by human factors. Generally, the defective rate of manual operation is about 20%. , and the use of automatic welding trolleys has no welding defect rate, so its comprehensive benefits are nearly 200% higher than manual welding.

4.High degree of automation, ensuring the stability of welding quality.

5.No need for very skilled technical workers.

1.Reduce labor intensity and improve the working environment.

2.Improve work efficiency, which is 1.5 times that of manual welding.

3.Avoid poor weld quality caused by human factors. Generally, the defective rate of manual operation is about 20%. , and the use of automatic welding trolleys has no welding defect rate, so its comprehensive benefits are nearly 200% higher than manual welding.

4.High degree of automation, ensuring the stability of welding quality.

5.No need for very skilled technical workers.

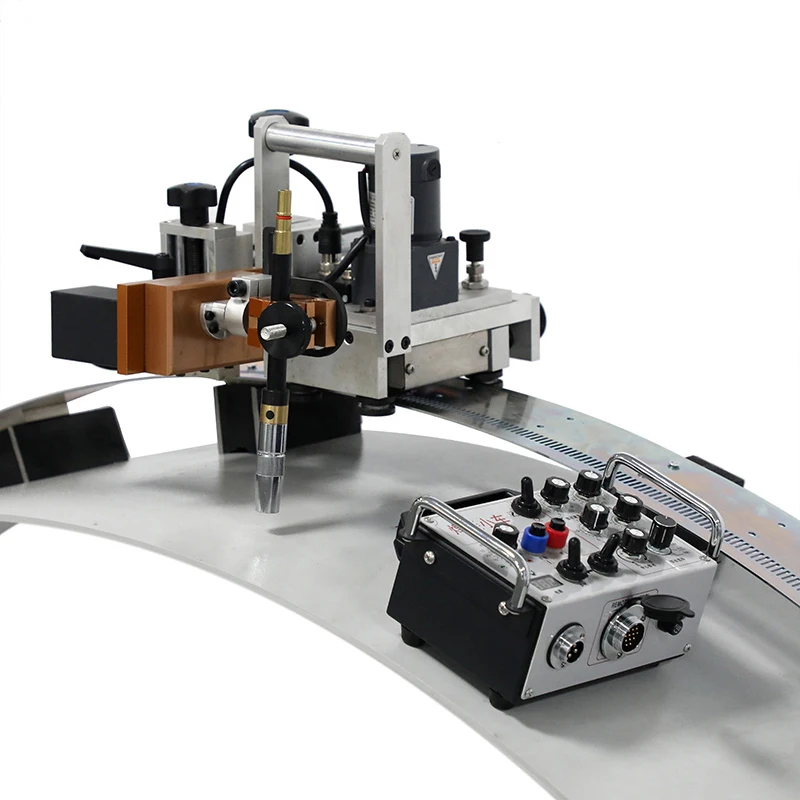

1) KA-H10 to achieve vertical welding, horizontal welding, ring seam welding and horizontal welding.

2) Have a straight line swing function. Various swing parameters such as swing mode, swinging amplitude, swing speed, swing center position and left and right stay time can be adjusted.

3) Use digital to display the running speed of the car.

4) In order to prevent the emergence of the bite and insufficient welding when welding, the left and right swing stop time adjustment function is set.

6) Have a fast return function.

7) Standard configuration provides a 1.8 -long track. The rail miniaturization light movement is convenient, and it can also be connected to extend the use.

roject | content | Remarks | ||

Small car | source | AC 220V, 50/60Hz | Optional: 24V lithium battery power supply | |

External dimensions | 400 x 330 x 320 | L*W*H | ||

weight | 14.6Kg | |||

Driving method | Gear driven | |||

Walking speed | 0-1040mm/min | Digital display | ||

Welding gun adjustment range | Up and down | ± 20mm | ||

around | ± 20mm | |||

Operation angle | 360 ° | |||

Perform angle | ± 90 ° | |||

track | Installation form | Magnetic detachable type | ||

External dimensions | 1800 x 110 x 1.8 | Length * width * height MM | ||

material quality | Elastic steel strip | 1.8 meters * 2 | ||

Track weight | 31Kg | Including magnets | ||

swing parameter | swing speed | 0-1520mm/min | ||

Swing amplitude | ± 20mm | |||

Left and right dwell time | 0-2s | |||

Center position | ± 5mm | |||

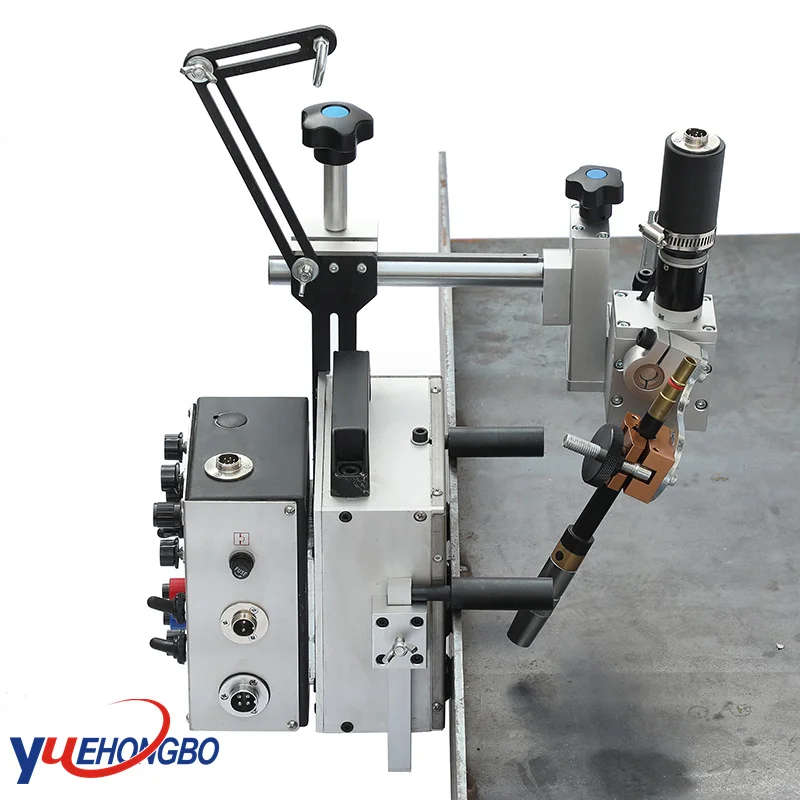

1.DC motor: the power device for the car to move. Use AC220V power supply.

2.Guide rail: Aluminum rigid guide rail, standard configuration is 1.5m, can be docked and extended for use.

3.Guide rail mounting magnet: rail fixing device. It can generate 60Kg of suction force and can be firmly adsorbed on the workpiece. Comes with a release handle for easy disassembly and movement of the track.

4.Control panel: The control center of the car, from which all actions are controlled.

5.Installation handle: trolley track wheel clutch device. During installation, twist this handle to drive the track wheel to open. After the track wheel is stuck on the track, loosen the handle and the track wheel will automatically lock. When the handle is in the half-clutch state, the quick return function can be achieved.

6. XY slider: adjustment mechanism for welding gun position. The adjustment range in the X direction is ±20mm, and the adjustment range in the Y direction is ±20mm.

7.Swing motor: the driving device of the oscillator. It uses a high-precision DC motor with a power of 6W.

8.Welding gun clamp: the clamping device of the welding gun. The angle of the welding gun can be adjusted with an adjustment range of ±90°.

2.Guide rail: Aluminum rigid guide rail, standard configuration is 1.5m, can be docked and extended for use.

3.Guide rail mounting magnet: rail fixing device. It can generate 60Kg of suction force and can be firmly adsorbed on the workpiece. Comes with a release handle for easy disassembly and movement of the track.

4.Control panel: The control center of the car, from which all actions are controlled.

5.Installation handle: trolley track wheel clutch device. During installation, twist this handle to drive the track wheel to open. After the track wheel is stuck on the track, loosen the handle and the track wheel will automatically lock. When the handle is in the half-clutch state, the quick return function can be achieved.

6. XY slider: adjustment mechanism for welding gun position. The adjustment range in the X direction is ±20mm, and the adjustment range in the Y direction is ±20mm.

7.Swing motor: the driving device of the oscillator. It uses a high-precision DC motor with a power of 6W.

8.Welding gun clamp: the clamping device of the welding gun. The angle of the welding gun can be adjusted with an adjustment range of ±90°.

1.DC motor: the power device for the car to move. Use AC220V power supply.

2.Guide rail: Aluminum rigid guide rail, standard configuration is 1.5m, can be docked and extended for use.

3.Guide rail mounting magnet: rail fixing device. It can generate 60Kg of suction force and can be firmly adsorbed on the workpiece. Comes with a release handle for easy disassembly and movement of the track.

4.Control panel: The control center of the car, from which all actions are controlled.

5.Installation handle: trolley track wheel clutch device. During installation, twist this handle to drive the track wheel to open. After the track wheel is stuck on the track, loosen the handle and the track wheel will automatically lock. When the handle is in the half-clutch state, the quick return function can be achieved.

6. XY slider: adjustment mechanism for welding gun position. The adjustment range in the X direction is ±20mm, and the adjustment range in the Y direction is ±20mm.

7.Swing motor: the driving device of the oscillator. It uses a high-precision DC motor with a power of 6W.

8.Welding gun clamp: the clamping device of the welding gun. The angle of the welding gun can be adjusted with an adjustment range of ±90°.

2.Guide rail: Aluminum rigid guide rail, standard configuration is 1.5m, can be docked and extended for use.

3.Guide rail mounting magnet: rail fixing device. It can generate 60Kg of suction force and can be firmly adsorbed on the workpiece. Comes with a release handle for easy disassembly and movement of the track.

4.Control panel: The control center of the car, from which all actions are controlled.

5.Installation handle: trolley track wheel clutch device. During installation, twist this handle to drive the track wheel to open. After the track wheel is stuck on the track, loosen the handle and the track wheel will automatically lock. When the handle is in the half-clutch state, the quick return function can be achieved.

6. XY slider: adjustment mechanism for welding gun position. The adjustment range in the X direction is ±20mm, and the adjustment range in the Y direction is ±20mm.

7.Swing motor: the driving device of the oscillator. It uses a high-precision DC motor with a power of 6W.

8.Welding gun clamp: the clamping device of the welding gun. The angle of the welding gun can be adjusted with an adjustment range of ±90°.

Qingdao Yuehongbo Welding and Cutting Equipment Co., Ltd. was established in 2012. It is an entity company integrating design, research and development, manufacturing and sales.

The company's products include automatic welding trolleys, special trolleys for all-position pipeline welding, weld seam laser trackers, visual tracking systems, welding oscillators, special equipment for corrugated board welding, special machines for straight seam plate welding, etc. The products are mainly aimed at large and medium-sized welding companies, and the scope of use includes: steel structure, shipbuilding, bridge, automobile industry and other manufacturing companies. It can realize different welding processes such as horizontal butt joint, right angle joint, vertical butt joint, vertical angle joint, circumferential pipe welding, horizontal butt joint, horizontal angle welding, etc.

The products are sold in more than 20 domestic autonomous regions in China, and exported to more than 20 countries and regions such as Southeast Asia, Europe and the United States. Comprehensive economic indicators (including productivity, sales, and profits) have been leading in the welding equipment industry.

We will follow the purpose of creating value for customers and providing opportunities for employees, and in the corporate style of "pursuing transcendence, harmonious development" and "unity and cooperation, integrity and truthfulness".

We look forward to cooperating with friends at home and abroad to create a brilliant future.

Q1:Is your company a trading one or a factory?

A:Factory and trade (we have our own factory site.)

Q2:How many years have you been producing welding equipment?

A:We have been in this industry for more than 10 years

Q3:Which payment terms are you accepted?

A:T/T

Q4:When to deliver the goods after the order is placed?

A:It depends on the quantity of the products. Generally we can arrange shipment after 15 to 20 days.

Q5. Does your company accept customization?

We have excellent design team, and we accept OEM.

Q6.:What's the shipping method?

A: International express and sea transportation,Depends on the customer

Q7: Can you send me the video to show how the machine works?

A: Certainly, we have made video of every machine.

Q8: How can I know your machine works well?

A: Before delivery, we shall test the machine working condition for you.And we warmly welcome you to China for inspection.

A:Factory and trade (we have our own factory site.)

Q2:How many years have you been producing welding equipment?

A:We have been in this industry for more than 10 years

Q3:Which payment terms are you accepted?

A:T/T

Q4:When to deliver the goods after the order is placed?

A:It depends on the quantity of the products. Generally we can arrange shipment after 15 to 20 days.

Q5. Does your company accept customization?

We have excellent design team, and we accept OEM.

Q6.:What's the shipping method?

A: International express and sea transportation,Depends on the customer

Q7: Can you send me the video to show how the machine works?

A: Certainly, we have made video of every machine.

Q8: How can I know your machine works well?

A: Before delivery, we shall test the machine working condition for you.And we warmly welcome you to China for inspection.

Похожие товары

Автоматический сварочный аппарат 5050 колонки-и-стрелы-сварочные манипуляторы

Сварочный аппарат с прямым швом из нержавеющей стали

1 066 585,65 ₽ - 1 072 055,32 ₽

KA-H5G Высокое качество всасывания филе сварочная тележка двойной пистолет сварочный автоматический

109 393,40 ₽ - 147 681,09 ₽

KA-H5G небольшая лампа в размерах боковая всасывающая сварочная тележка с двойным пистолетом, автоматическая сварка

109 393,40 ₽ - 147 681,09 ₽

Ультразвуковой сварочный аппарат, 20 кГц, 6000 Вт

1 093 934,00 ₽

Ультразвуковая машина для сварки металла полуавтоматическая или автоматическая ультразвуковая машина для сварки металла с китайским производителем

984 540,60 ₽ - 1 093 934,00 ₽

USB флэш-накопитель блистер упаковка сварочный аппарат

382 876,90 ₽ - 546 967,00 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

OrionStars онлайн-машина для рыбалки и свинга высокоприбыльная монетная игра США оптовая продажа агент с высокой прибылью Разыскивается

Рекламный надувной самолет украшение для костюма самолета ходячие костюмы продажи

C100 % восковая ткань с принтом китайские поставщики поставляют настраиваемые печатные африканские восковые ткани

0,93-0,97 $

Прямые продажи с фабрики могут быть оптовые складные тележки для покупок Удобные и уличные продуктовые

8,39-9,89 $

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $