Точность лазерное оборудование IPG большой мощности 6KW металлическая листовая труба для обработки волоконно лазерной резки с сертификацией CE

- Категория: >>>

- Поставщик: Accurl Cnc Machine (anhui) Manufactory Co. Ltd.

Сохранить в закладки 1601258520918:

Описание и отзывы

Характеристики

Products Description

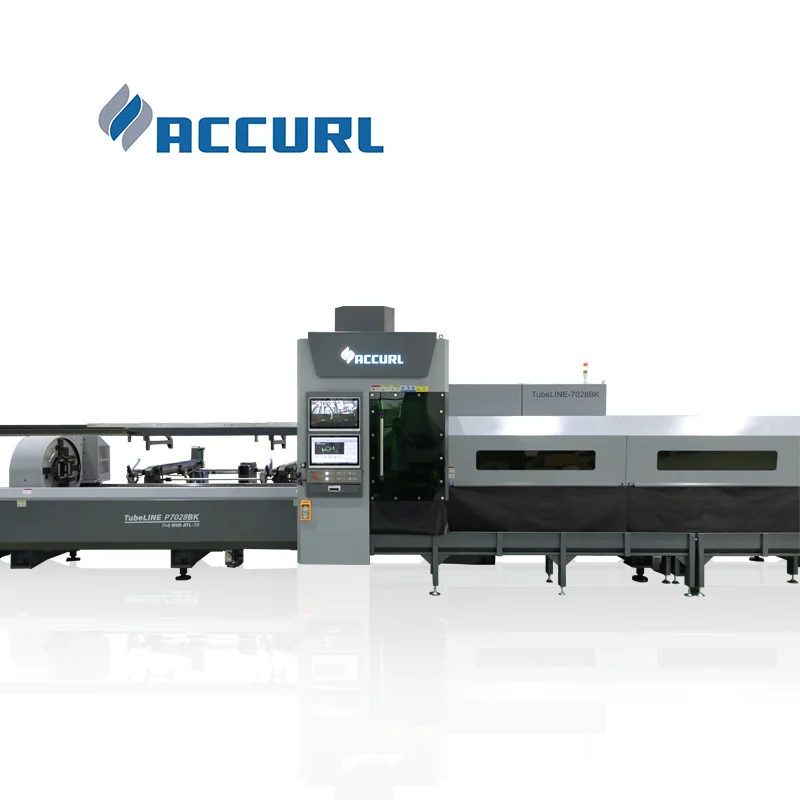

ACCURL TubeLINE BK Series FIBER LASER TUBE CUTTING MACHINE

ACCURL TubeLINE BK Series is a compact and efficient tube cutting solution with advanced technical features for optimal performance.It offers versatility, ease of use,& best-in-class engineering for processing various tube shapes. Ideal for frequent production changeovers and adapting to different materials. Invest in TubeLINE for a profitable cutting solution

Intelligent operation system, with tubes graphs warehouse and integrated splicing process of multiple tubes. Professional control system, to realize intelligent cooperation of machine tools. Butler-type machine tool debugging and maintenance plan, safe and reliable. Tube cutting graphics flattening and other rich cutting auxiliary functions, convenient and intuitive.

STANDARD:

Machine Model: TubeLINE-SERIES

Laser Cutting Head:ACCURL BLT Series (Auto Focus)

Laser Sources: IPG & MAX Photonics

Material Size Range: Round tube 15-500mm

For LoadMaster Tube: 6M / 7M / 9M / 12M

Maximum Tube Length & Weight: 12000mm, 1200kg

Motion System: Yaskawa Servos & Drivers - X,Y,Z Axis

X.Y.Z axis position accuracy: ±0.02mm

User Interface (HMl):ACCURL 21.5”Touch Screen with Camera Display

Fume Extraction:With Optional Dust Collector

Class IV safety system and CE marking

Laser Cutting Head:ACCURL BLT Series (Auto Focus)

Laser Sources: IPG & MAX Photonics

Material Size Range: Round tube 15-500mm

For LoadMaster Tube: 6M / 7M / 9M / 12M

Maximum Tube Length & Weight: 12000mm, 1200kg

Motion System: Yaskawa Servos & Drivers - X,Y,Z Axis

X.Y.Z axis position accuracy: ±0.02mm

User Interface (HMl):ACCURL 21.5”Touch Screen with Camera Display

Fume Extraction:With Optional Dust Collector

Class IV safety system and CE marking

MACHINE BODY

ACCURL steel frames bed adopts welding

structure, rough machining after annealing, then vibration aging treatment, and then finishing, can completely eliminate the stress of welding and machining,good rigidity, high precision, can maintain long time use without deformation.

structure, rough machining after annealing, then vibration aging treatment, and then finishing, can completely eliminate the stress of welding and machining,good rigidity, high precision, can maintain long time use without deformation.

CHUNKS AND CLAWS

Two high quality rotate chuck move with synchronous rotation, which ensure tube holding more steady . It reduce tube vibration to minimum, with solid guarantee for high accuracy in complicate tube figure.Suitable for cutting tube with diameter range from Ø20mm to Ø320mm.

FRONT CHUNKS

The X、Y、Z linear Axis and A、B rotary Axis both adopt imported large torque servo motor, high precision, high speed, large torque, large inertia, stable and durable performance, which ensures the high speed and acceleration of the whole machine.

MEDIUM CHUNKS

The three chuck real-time to maintain the pipe before and afterthree-point clamping positioning, cutting space-time running speed can achieve max stable cutting, relative cutting efficiency to be high.

REAR CHUNKS

Independent research and development of the chuck with good sealing and motion characteristics, can hold square tube, round tube, elliptical tube, flat tube, triangle tube, I-beam and other materials.

CNC CONTROL SYSTEM

The FSCUT-5000 laser cutting control system of an tube laser cutting control system. Widely used in the field of metal and

nonmetal laser cutting. Because of its outstanding performance in the field of fiber laser cutting, by the vast number of high-end users.

nonmetal laser cutting. Because of its outstanding performance in the field of fiber laser cutting, by the vast number of high-end users.

TUBE CUTTING HEAD

CUTTING HEAD RAYTOOLS

The RAYTOOLS AG comes with the external motor and the built-in drive unit through the linear driver and the focusing lens can automatically change the position in the range of 25mm. The user can set the focus continuously through the program to complete the rapid perpiercing of thick sheets or other different thickness and material sheets.

CUTTING HEAD PRECITEC LIGHTCUTTER AUTO FOCUS(OPTIONAL)

The cutting head LightCutter 2.0 is the perfect solution for efficient and cost-effective laser cutting. The new generation of our Light Cutter family is designed for cutting applications in the medium power range up to 4 kW and is characterized by a high cutting quality for all metals - especially mild steel, stainless steel and aluminum.

AUTOMATIC LOADING SYSTEM

SEMI-AUTOMATIC LOADING SYSTEM SAT-60

*Transmission module: Place the pipe on the loading belt manually and the belt will transport the pipe forward.

* Material Misalignment module: The pipe is separated from the root, misplaced to the loading jaws.

* Loading module: The loading jaws send the pipe to the loading support of the main bed one by one.

* Loading Size: The size range of loading material is Ø25- Ø120,square pipe 25-120,can load round pipe,single pipe bearing 120Kgs.

* Material Misalignment module: The pipe is separated from the root, misplaced to the loading jaws.

* Loading module: The loading jaws send the pipe to the loading support of the main bed one by one.

* Loading Size: The size range of loading material is Ø25- Ø120,square pipe 25-120,can load round pipe,single pipe bearing 120Kgs.

AUTOMATIC MECHANICAL LOADING SYSTEM ATL-60

* Height Limit module: Automatically distinguish the long and short sides of the rectangular tube to ensure that each rectangular tube is laid flat and forward.

* Material framemodule: The whole bundle of pipes is hoisted and loaded into the material frame.

* Length measuring module: Flatten the pipe to the length of the pipe and transfer the date to the host.

* Loading Size: The size range of loading material is φ25-120,square pipe 25-120,can load round pipe,single pipe bearing 120Kgs. The first loading time is less than of equal to 70s,and the subsequent loading time is less than or equal to 20s.

* Material framemodule: The whole bundle of pipes is hoisted and loaded into the material frame.

* Length measuring module: Flatten the pipe to the length of the pipe and transfer the date to the host.

* Loading Size: The size range of loading material is φ25-120,square pipe 25-120,can load round pipe,single pipe bearing 120Kgs. The first loading time is less than of equal to 70s,and the subsequent loading time is less than or equal to 20s.

Specification

Model | TubeLINE A Series | TubeLINE BK Series | TubeLINE D Series | |

Power | 1500W~6000W | 6000W~15000W | ||

Processing range | φ240 | φ200 | φ280 | φ320 | φ360 | φ500 | |

For LoadMaster Tube | 6000mm | 6000mm / 7000mm / 9000mm | 9000mm / 12000mm | |

Max no-load running speed | 100m/min | 100m/min | 101m/min | |

Max idle speed | 100r/min | 100r/min | 85r/min | |

Max mass of single pipe | 250kg | 350kg | 1200kg | |

For unloading | ≤2000mm | ≤3000mm / 6000mm | ≤6000mm / 9000mm / 12000mm | |

Related Products

Company Profile

WHY CHOOSE ACCURL ?

■The right tube laser.

■Innovative features such as bevel cutting.

■Comprehensive technology and cutting data.

■Ergonomic machine concepts.

Our functional features and integrated know-how support your tubes and profiles every step of the way through the machine. Each component is designed to achieve optimal results. Real benefits every step of the way.

■Innovative features such as bevel cutting.

■Comprehensive technology and cutting data.

■Ergonomic machine concepts.

Our functional features and integrated know-how support your tubes and profiles every step of the way through the machine. Each component is designed to achieve optimal results. Real benefits every step of the way.

A comparison of the production steps involved in laser tube cutting and conventional manufacturing

WE GOT 5 STARS RATING!

Exhibition

Product packaging

We are currently reviewing our product packaging from the angles of waste-reduction and resource-saving. We are also working on improving transportation efficiency from the design phase of product development.

1.Our wooden case is after fumigation treatment. Needn't timber inspection, saving shipping time.

2.All the spare parts of the machine were covered by the some soft materials mainly using pearl wool.

2.All the spare parts of the machine were covered by the some soft materials mainly using pearl wool.

3.The outmost is wooden case with fixed formwork.

4.The bottom of the wooden case has firm iron jack, convenient to handing and transport.

4.The bottom of the wooden case has firm iron jack, convenient to handing and transport.

Our Serives

The use of an interferometer records the machines X and Y axis movement during cutting to ensure accuracy.

Adjustments are made to ensure machine is precisely tuned before shipment.

Adjustments are made to ensure machine is precisely tuned before shipment.

A Marble test is performed to measure the X and Y axis, calculating any necessary adjustments to ensure perfect level and alignment along length of machine.

A collimator is run along the full length of the guide rail, testing for

straightness. Adjustments are made as required to ensure linear accurae linear accuracy.

FAQ

1.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

2.What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

3.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.

4.What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction.

5.Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

6.How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

Похожие товары

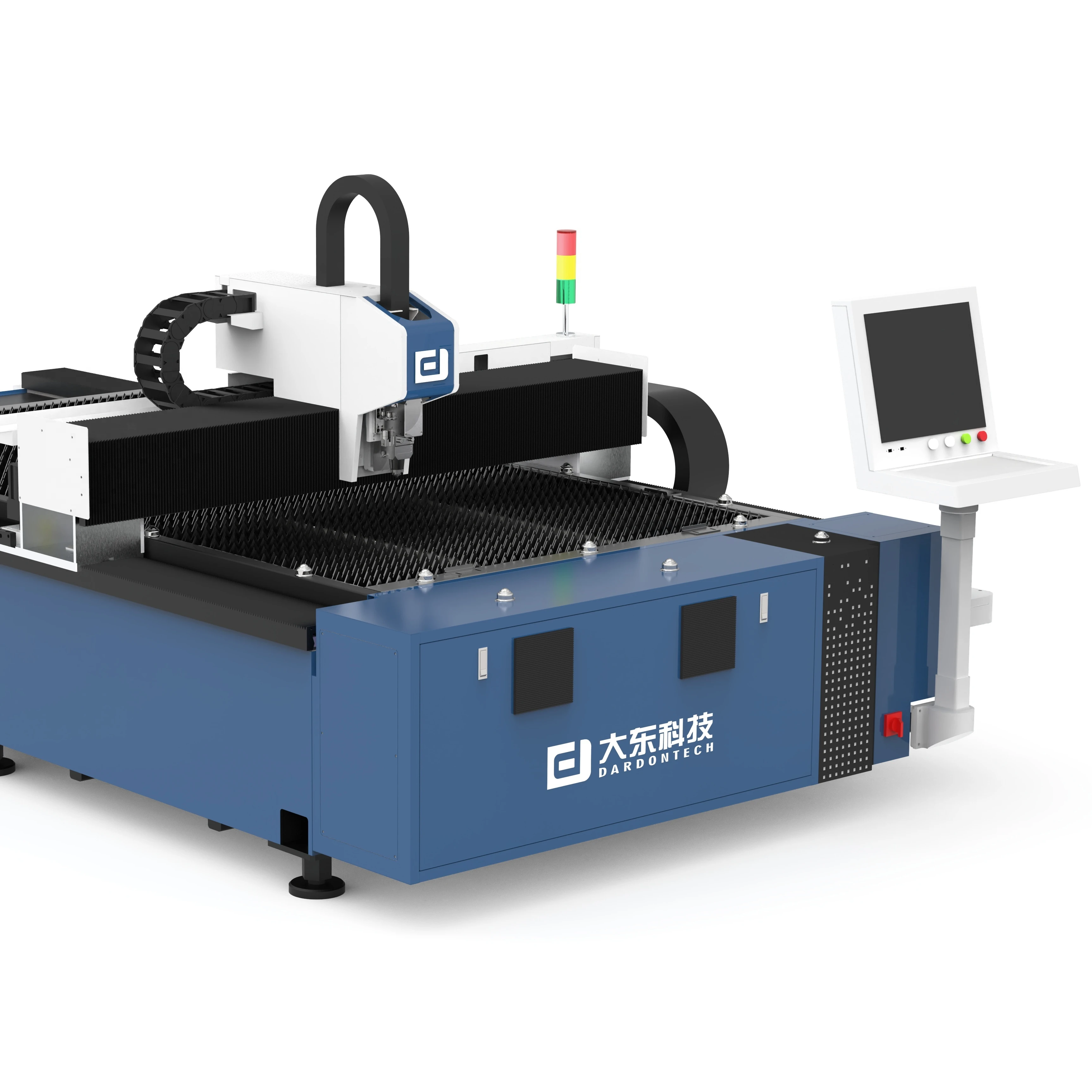

Одиночная платформа 3000 Вт Волоконно-Лазерная резка машина

2 187 868,00 ₽ - 2 265 537,32 ₽

G-WEIKE LF3015LN машины для лазерной резки листового металла из нержавеющей стали

2 078 474,60 ₽ - 2 406 654,80 ₽

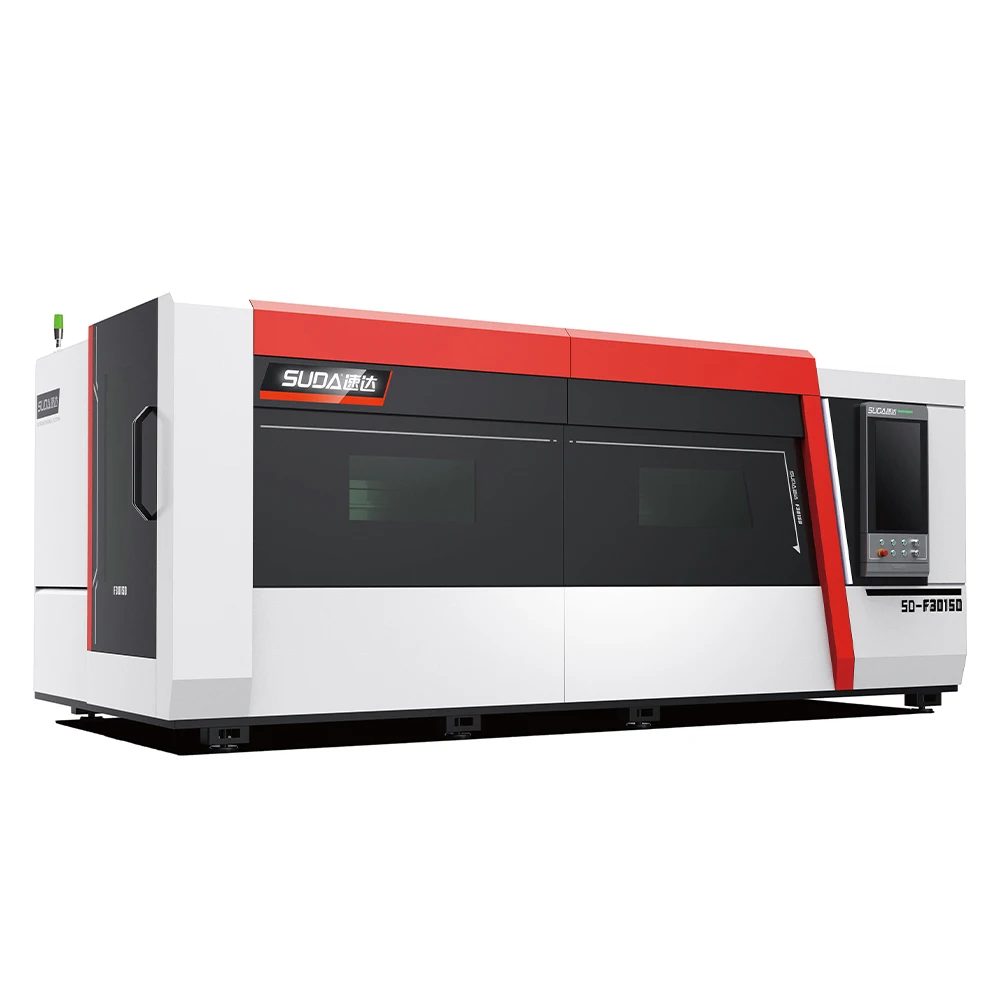

3015 закрытая крышка листового металла лазерный резак портативный волоконно-лазерный станок для резки

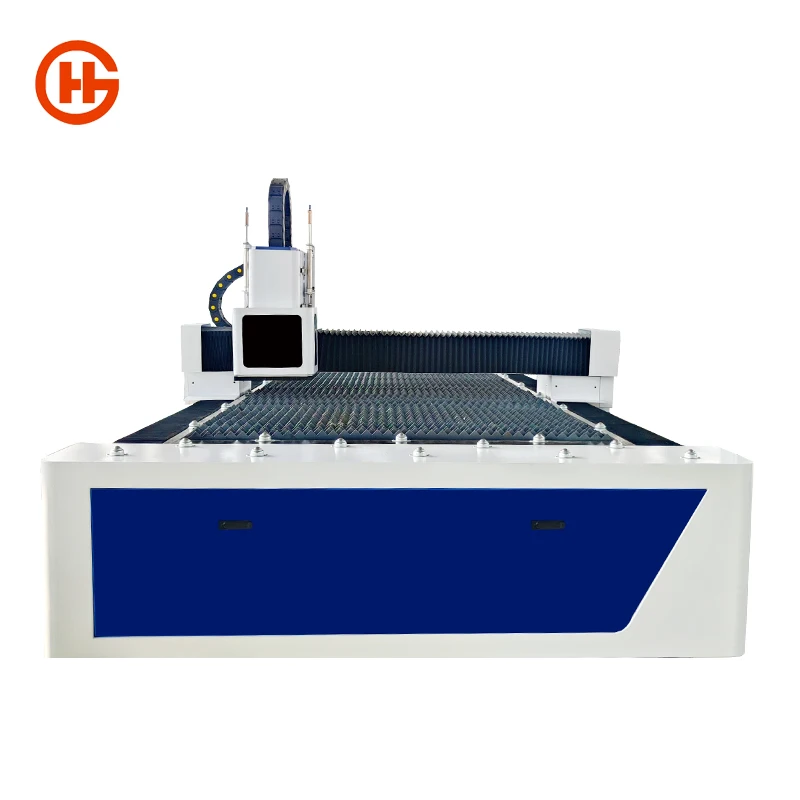

0,8 мм из нержавеющей стали волоконно-лазерная резка для ворот 3000X1500 мм Лазерная резка машина 2 кВт

1 017 358,62 ₽ - 1 236 145,42 ₽

Raycus лазерный резонатор Raycus лазерный 3000 Вт 3 кВт станок для резки труб

1 093 934,00 ₽ - 1 640 901,00 ₽

Волоконно-лазерная машина для резки 3000 ватт автоматическая для резки металлических труб и пластин и труб волоконно-лазерная резка

481 221,57 ₽ - 535 918,27 ₽

2000 Вт, популярные высокие продажи, лазерная резка, машина для резки труб, волоконно-лазерная 3000*1500 мм, резка

2 034 717,24 ₽ - 2 570 744,90 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $