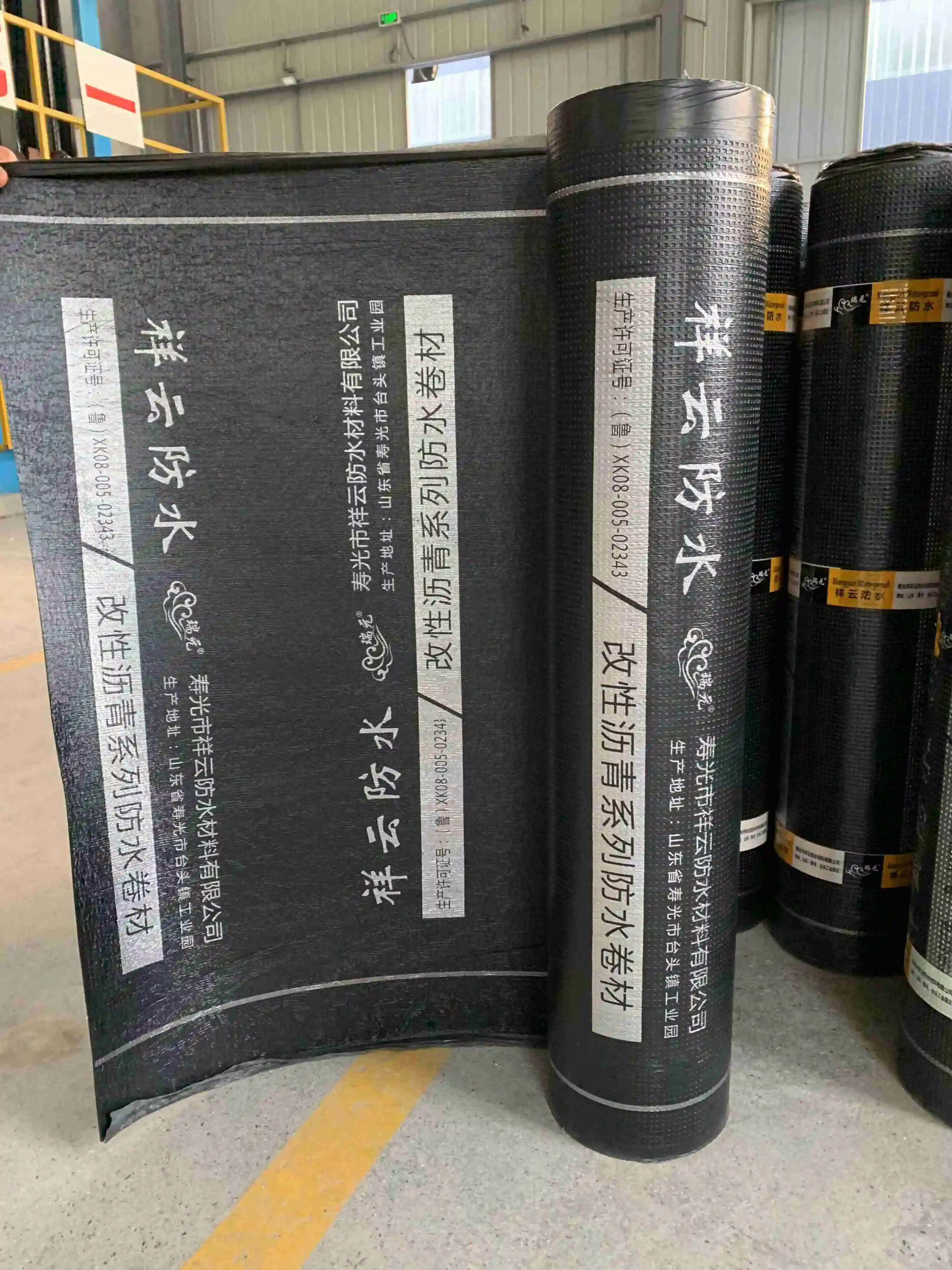

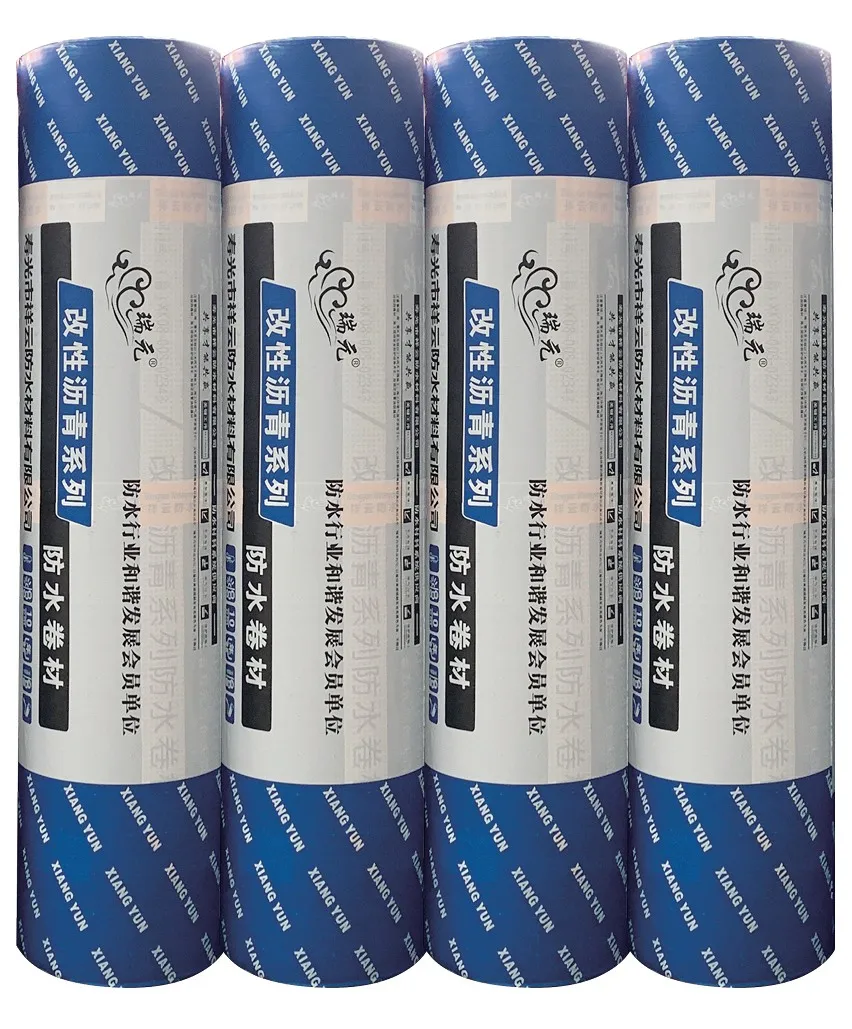

Модифицированный плавательный бассейн из фольги эластомер модифицированный асфальт битумная Водонепроницаемая Мембрана для бетонной крыши

- Категория: >>>

- Поставщик: Shouguang Xiangyun Waterproof Material Co. Ltd.

Сохранить в закладки 1601258936248:

Описание и отзывы

Характеристики

Product Description

Specification

Serial Number | Item | index | |||||||||

PY | G | PY | G | PYG | |||||||

1 | 3mm | 2100 | |||||||||

Soluble content | 4mm | 2900 | |||||||||

(g/㎡)2 | 5mm | 3500 | |||||||||

Experimental phenomenon | Tire base non combustible | Tire base non combustible | |||||||||

2 | heat resistance | ℃ | 90 | 105 | |||||||

s mm | 2 | ||||||||||

Experimental phenomenon | No flow pool, dripping | ||||||||||

3 | Low temperature flexibility (℃) | -20 | -25 | ||||||||

4 | Impermeability (30 minutes) | 0.3Mpa | 0.2Mpa | 0.3Mpa | |||||||

Maximum peak tensile force (N/50mm) ≥ | 500 | 350 | 800 | 500 | 900 | ||||||

5 | pulling | Secondary peak tensile force (N/50mm) ≥ | 800 | ||||||||

Elongation rate | Experimental phenomenon | During the stretching process, some parts of the specimen showed no cracking of the asphalt coating or splitting with the tire base | |||||||||

Maximum peak elongation (%) z | 30 | 40 | |||||||||

6 | Mass increase after immersion in water | Extension rate during sub peak hours (%) ≥ | 15 | ||||||||

PE.S" | 1.0 | ||||||||||

7 8 | (%)s | 2.0 | |||||||||

thermal ageing | M | 90 | |||||||||

Tensile retention rate (%) 2 | 80 | ||||||||||

Elongation retention rate (%) ≥ | -15 | -20 | |||||||||

Low temperature flexibility (℃)“ | No cracks | ||||||||||

0.7 | 0.7 | 0.3 | |||||||||

1.0 | |||||||||||

9 | Oil leakage number 5 | 2.0 | |||||||||

10 11 | Joint peel strength (N/mm) 2 Tear strength of nail rod * N | 1.5 | 300 | ||||||||

12 | () 2 矿物粒料粘附性 () 5 | 2.0 | |||||||||

13 | The thickness of the asphalt coating layer on the lower surface of the roll material c (mm) ≥ | 1.0 | |||||||||

14 | No sliding, flowing, or dripping | ||||||||||

Artificial climate Accelerated aging | Tensile retention rate (%) | 80 | |||||||||

appearance | -15 | -20 | |||||||||

Low temperature flexibility (℃) | No cracks | ||||||||||

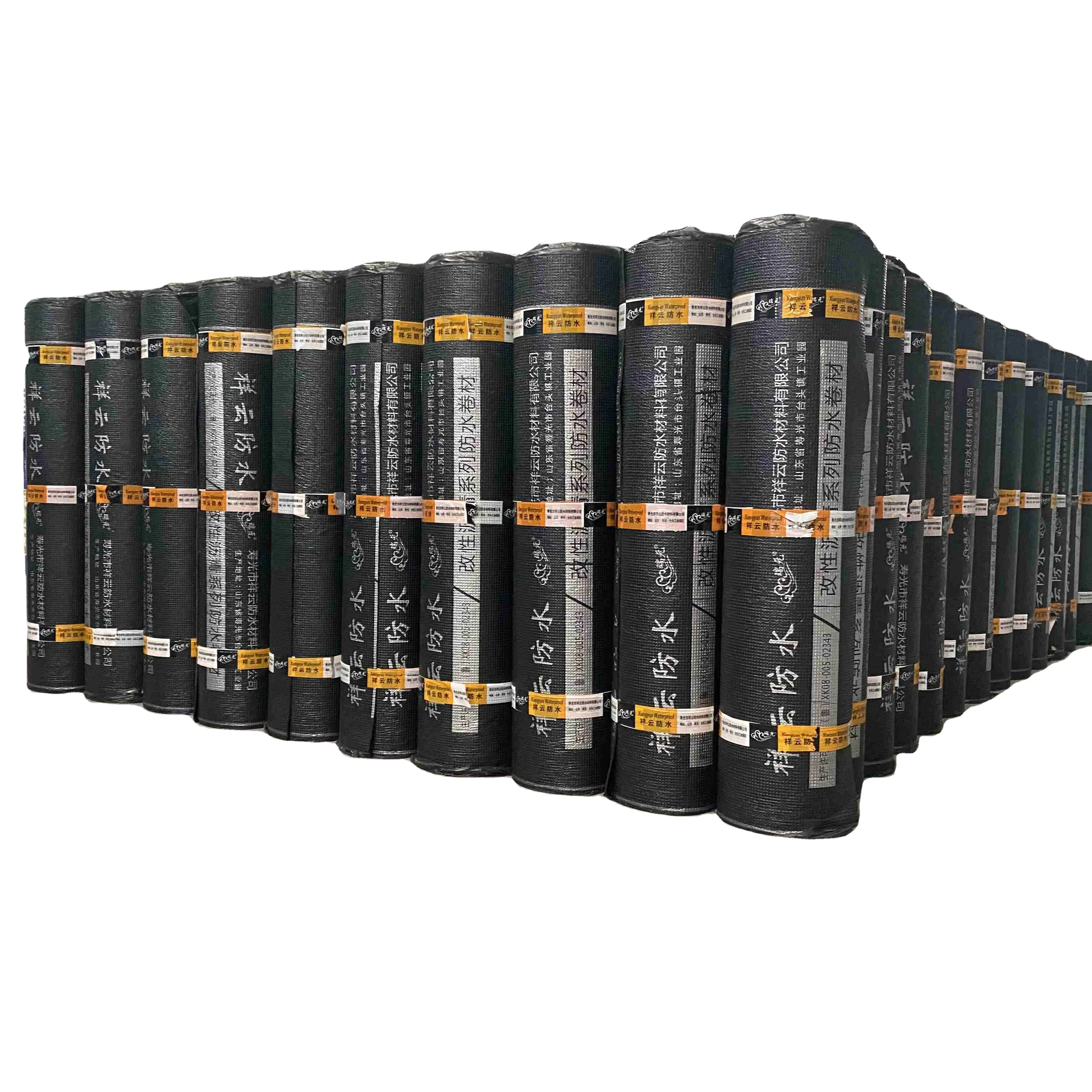

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

Shouguang Xiangyun Waterproof Materials Co., Ltd

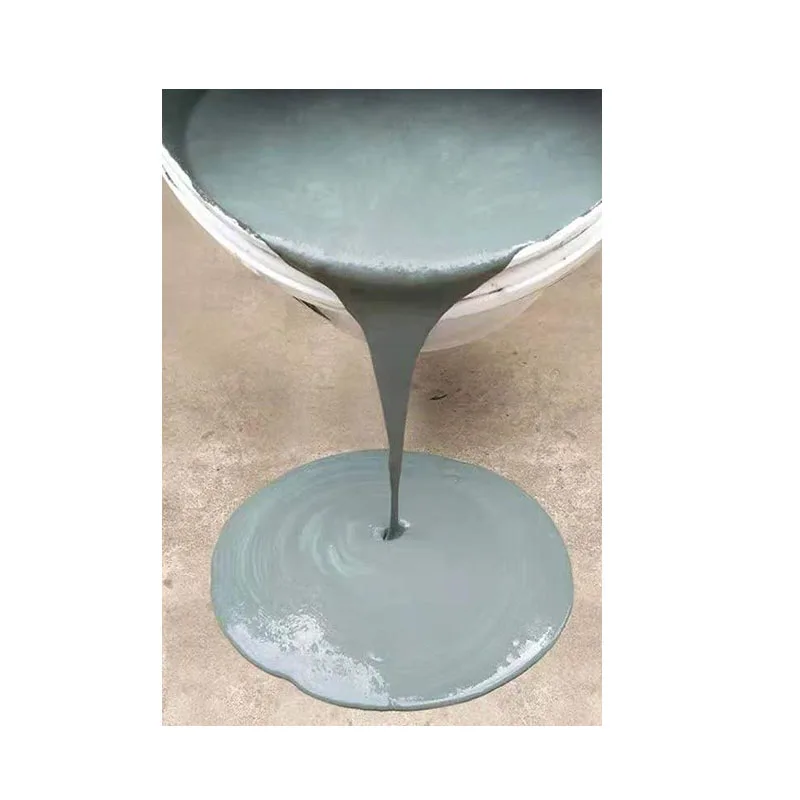

Shouguang Xiangyun Waterproof Materials Co., Ltd. has modern SBS and APP production lines with an annual output of 20 million square meters; We have a production line for polyethylene polypropylene composite waterproofing membranes with an annual output of 5 million square meters, as well as production lines for self-adhesive rubber modified asphalt waterproofing membranes, self-adhesive polymer modified asphalt waterproofing membranes, colored asphalt felt tiles, colored polyurethane waterproof coatings, polymer cement waterproof coatings, leak sealing agents, and other products. We are a specialized new waterproofing material enterprise that integrates production, scientific research and construction, and sales.Main products of the company: self-adhesive polymer modified asphalt waterproofing membrane, fast response adhesive strong cross membrane self-adhesive membrane, elastomer modified asphalt waterproofing membrane, plastic modified asphalt waterproofing membrane, polymer self-adhesive membrane (non asphalt based) waterproofing membrane, polymer modified asphalt root puncture resistant waterproofing membrane, gold tire polymer root puncture resistant waterproofing membrane, root puncture resistant polyvinyl chloride PVC waterproofing material, root puncture resistant polymer polyethylene polypropylene waterproofing membrane, polymer polyethylene propylene (polyester) waterproofing membrane, polyethylene polypropylene special dry powder adhesive, polyethylene (PVC) waterproofing membrane, thermoplastic polyolefin (TPO) waterproofing membrane, EPDM rubber waterproofing membrane, colored polyurethane waterproof coating (911. spu), spray cured rubber asphalt waterproof coating, non curing rubber Asphalt waterproof coating, high elasticity thick acrylic waterproof coating Polymer cement (J5) composite waterproof coating, cement-based permeable crystalline waterproof coating, water-based 951 polyurethane waterproof coating, high polymer modified asphalt waterproof coating, K11 waterproof coating, etc. The company has the national second level qualification for waterproofing, anti-corrosion and insulation, and can undertake large-scale waterproofing projects. Xiangyun Company strives for survival through quality and development through reputation, and welcomes friends from all walks of life to visit!

Certifications

Exhibition

FAQ

Похожие товары

Водонепроницаемый продукт Yu Ru, акриловое гидрофобное покрытие и водостойкость краски для бетонной крыши

248,42 ₽ - 270,02 ₽

Новый нагнетательный насос высокого давления с двойным впрыском, водостойкая машина для розлива полиуретановой эпоксидной смолы

14 580,84 ₽ - 15 120,87 ₽

Композитный водостойкий материал JS на основе цемента, покрытие крыши из полимерного цемента

108,01 ₽ - 129,61 ₽

Toln туалета Невидимый герметизирующий прозрачный водонепроницаемый герметик клей для лакокрасочного покрытия клейкая жидкость для стен дома

99,37 ₽ - 122,05 ₽

Проектная специальная цементная лента высокой плотности с закрытыми ячейками

27,01 ₽ - 48,61 ₽

JS, полимерный цемент на цементной основе, Js, водонепроницаемое покрытие для бассейна, Очищающий жидкий резиновый оконный упаковщик

129,61 ₽ - 172,81 ₽

10 мм X 150 мм, высоконапорный инжектор из смолы

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $