Прямые продажи с завода машина для производства мелких кормов домашних животных многофункциональная кошек и собак

- Категория: >>>

- Поставщик: Lerford Machine LLCLerford LLC

Сохранить в закладки 1601259012764:

Описание и отзывы

Характеристики

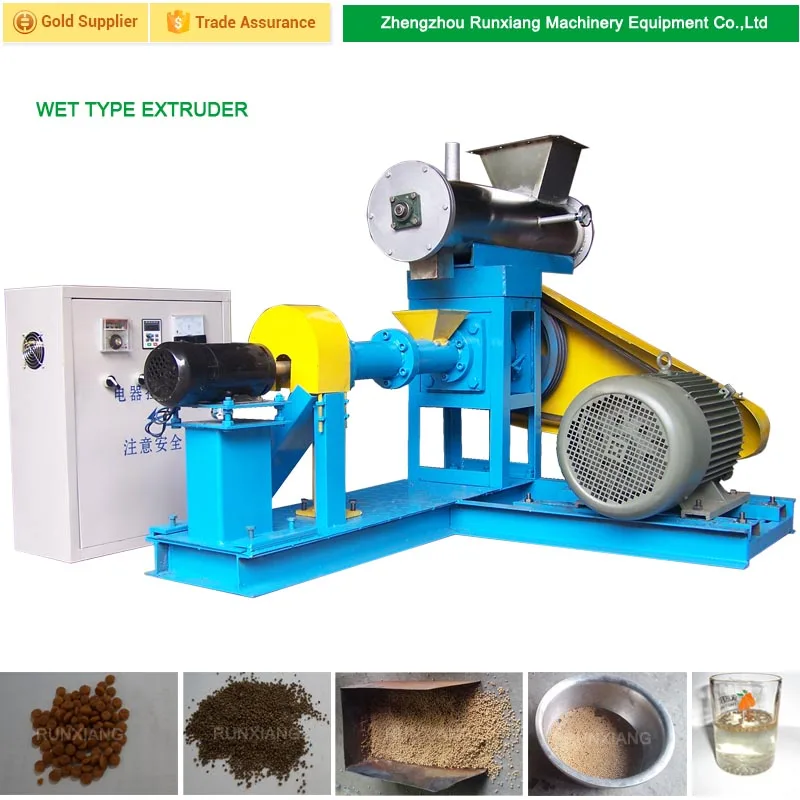

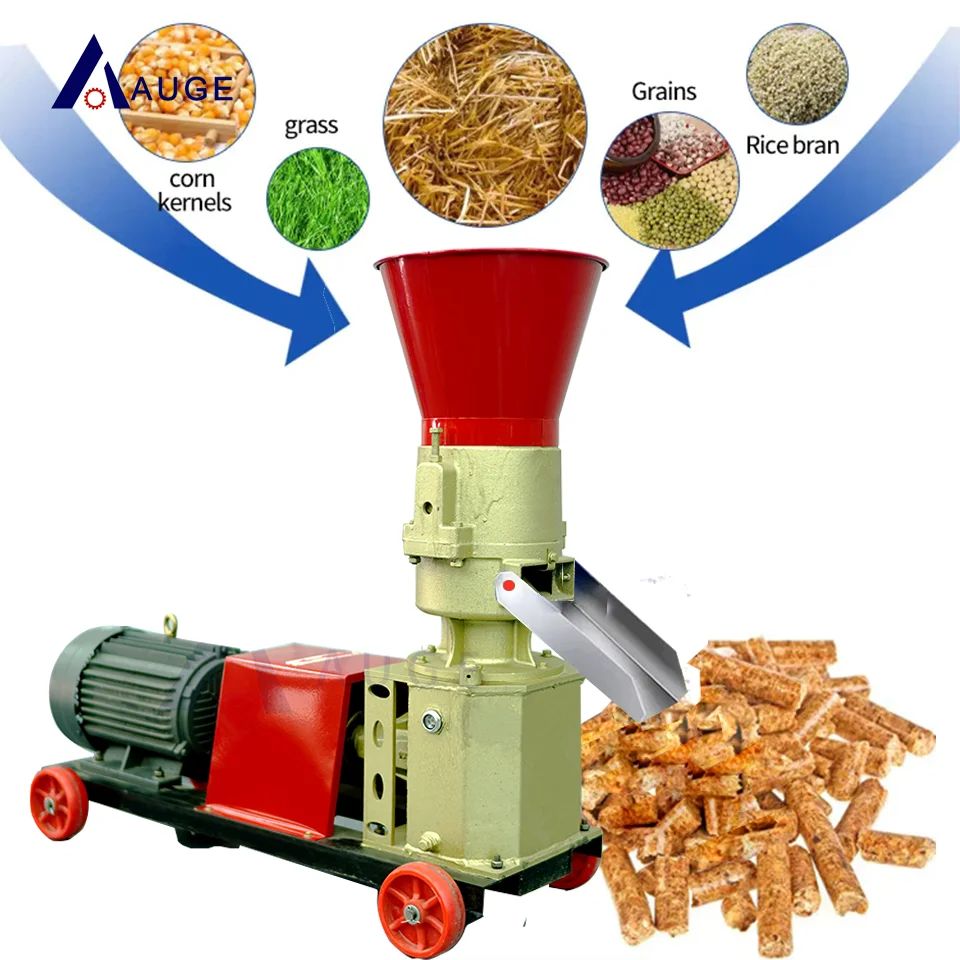

Feed pellet machine plays an important role in animal husbandry, which makes farmers' feeding more accurate and easy. Widely used in the production of various feed particles, such as poultry feed, livestock feed, pet feed, aquatic feed and so on. With the development of technology, feed pellet machine has two types: dry type and wet type. This paper mainly introduces the dry feed pellet machine, including its working principle, advantages, structural characteristics and applications.

The working principle of dry pet feed pellet machine

The working principle of dry pet feed pellet machine is to produce pellets from feed raw materials through molds. It consists of four main parts: the feeder, the temperer, the granulation chamber and the motor. First, raw materials are fed into the feeder, where they are guided and mixed into the conditioning chamber. In a temperer, the material is mixed and heated with steam, and then the humidity and temperature are adjusted to create the ideal environment for particle molding. After the material is adjusted, it is fed into the granulation chamber, where it meets the mold and the roller. A mold with many small holes shapes the material into particles, while a roller presses the material through the mold. Finally, the motor provides the necessary power to make all objects move and work efficiently.

Advantages of dry fish feed pellet machine

1. Suitable for making different types of feed pellets - dry feed pellets are widely used and can make feed pellets of different kinds of animals, including poultry, livestock, pets, fish.

2, low moisture content - As the name suggests, dry feed granule production of particles with low moisture content, easy to store, transport and handle.

3, cost-effective - dry pellet machine does not require any additional water or steam, which makes it more cost-effective than wet pellet machine. In addition, the pellets produced are of high quality and high nutritional value, which means that you do not need to add additional nutrients to your feed.

4, easy to operate - dry feed pellet machine is easy to operate and does not require any special training for the operator. In addition, they require less maintenance, which makes them ideal for small businesses and farms.

Structural characteristics of dry fish food extruder machine

1, feeder - feeder is the first part of the dry fish feed pellet machine. It is responsible for introducing raw materials into the granulation chamber. It consists of a hopper, an auger and a variable frequency motor.

2. Temperer - The temperer is where the ingredients are mixed and heated by steam. It creates the ideal environment for particle formation by regulating humidity and temperature. It also kills any bacteria present in the raw material.

3. Granulation chamber - The granulation chamber is where the raw material meets the mold and the roller. The mold has many small holes to form the material into particles. The roller presses the material through the mold.

4. Motor - The motor provides the necessary power to make everything move and work efficiently.

What are the benefits of feed pellets for animals?

1, convenient - pellet feeding is more convenient than the traditional feeding method. Farmers can precisely measure and regulate the amount of nutrition provided to animals, thereby optimizing livestock growth and development.

2. Nutrition - Pellet feed contains balanced nutrients that are essential for animal growth and development. They contain protein, fiber, minerals, and other nutrients necessary for a healthy, balanced diet.

3. Digestibility - The particles are made with a high-quality grinding process, making it easier for animals to digest and absorb. This allows animals to get more nutrients from the same amount of feed.

4. Cost effective - Feeding animals pellets is a cost-effective way to provide nutrition. It is more effective than traditional feeding methods, and the pellets are made from high-quality raw materials, which reduces waste and spoilage.

Application of feed pellet machine

1. Agriculture - Agricultural enterprises use feed pellet machines to produce pellet feed for livestock.

2. Aquaculture - pellet feed machine is used to produce pellet feed for fish farming.

3. Pet food production - pet food manufacturers use feed pellet machines to produce pet feed pellets.

4. Animal feed additive supplier - feed pellet machine is used to manufacture animal feed additives.

Technical Date of Floating Fish Feed Pellet Making Machine

| Model | WSJY-40 | WSJY- 50 | WSJY-60 | WSJY-70 | WSJY-80 | WSJY-90 | WSJY-120 | WSJY—135 | WSJY-160 | WSJY-200 |

| Capacity --- kg/h | 30-40 | 60-80 | 120-150 | 180-250 | 300-350 | 400-450 | 500-700 | 800-1000 | 1200-1500 | 1800-2000 |

| Pelleting Diameter--- mm | 1-8 | 1—8 | 1 —10 | 1 —10 | 1 —10 | 1 —10 | 1 —10 | 1 –12 | 1 –12 | 1 –12 |

| Motor Power--- kw | 5 | 7.5 | 15 | 18.5 | 22 | 37 | 55 | 75 | 90 | 132 |

| Cutting Power--- w | 400 | 400 | 400 | 400 | 1100 | 1500 | 2200 | 2200 | 2200 | 3000 |

| Screw Rod Diameter-- mm | 40 | 50 | 60 | 70 | 80 | 90 | 120 | 135 | 160 | 200 |

| Cooking degree | >95% | >95% | >95% | >95% | >95% | >95% | >95% | >95% | >95% | >95% |

| Size(m) | 1.4*1.03*1.1 | 1.45*1.08*1.25 | 1.46*1.14*1.25 | 1.6*1.4*1.35 | 1.6*1.4*1.35 | 2.1*1.45*1.35 | 2.1*1.45*1.35 | 2.55*2.05*1.65 | 2.9*2.65*1.8 | 3*2.85*1.9 |

| Weight(kg) | 260 | 350 | 355 | 580 | 700 | 950 | 1700 | 1900 | 3600 | 4300 |

How to choose the right feed pellet machine?

1. Determine the type and size of feed that need to be processed: Different feed types and size requirements have different requirements for the process and equipment of feed pellet machine.

2. Safety and reliability: It is necessary to ensure that the feed pellet machine has good safety and reliability during use and can run stably for a long time.

3. Accuracy and efficiency: It is necessary to select feed pellet machines that can achieve certain accuracy and high efficiency, and can meet the production requirements

What's the difference between our company's machines and others?

1. Small equipment: the machine is small in size, covers less area, does not affect production, can adapt to the needs of different occasions.

2. High precision: Our feed pellet machine adopts modern precision testing technology, and there are professional technicians for testing and debugging.

3. Energy saving and environmental protection: Our feed pellet machine uses high-quality raw materials, has the characteristics of durability and energy saving and environmental protection, and can reduce the energy consumption of the production process.

What is the pre-sales and after-sales service of our factory?

1. Consultation - We provide our customers with expert advice to help them choose the right machine to meet their needs.

2. Installation - We provide machine installation services and technical support to ensure that your machine is running at its best.

3. Maintenance - We provide maintenance services to ensure that your machine is running at peak performance.

4. Repair - We provide repair services to quickly and efficiently solve any problems with your machine.

What are the advantages of our factory?

1. Quality - Our machines are made of quality materials and we are committed to quality control in all aspects of our business.

2. Experience - Our factory has many years of experience in the feed pellet machine industry. We deeply understand our customers' needs and are always looking for new ways to improve our machines.

3. Service - We provide excellent pre-sales and after-sales service to ensure that customers are satisfied with our machines.

4. Competitive prices - Our machines are offered at competitive prices, ensuring that our customers can afford the best quality products.

Похожие товары

Небольшая машина для гранулирования высокая производительность полная мини-обработка корма домашних животных

Хорошая обратная связь торговый центр для кормления птицы/машина производства кормов птицы/линия по производству гранул птицы машина

Машина для производства кормов домашних животных

Мини-гранулятор для корма животных

Сельскохозяйственная техника мини-машина для производства кормов рыб

Прямая Продажа с завода машина для производства кормов животных Высокоэффективная крупного рогатого скота настраиваемая прессования

Мелкий цыпленок дизельный рыбный конский корм для овец машина обработки кормов животных газовый двигатель курицы

Новые поступления

Новинки товаров от производителей по оптовым ценам