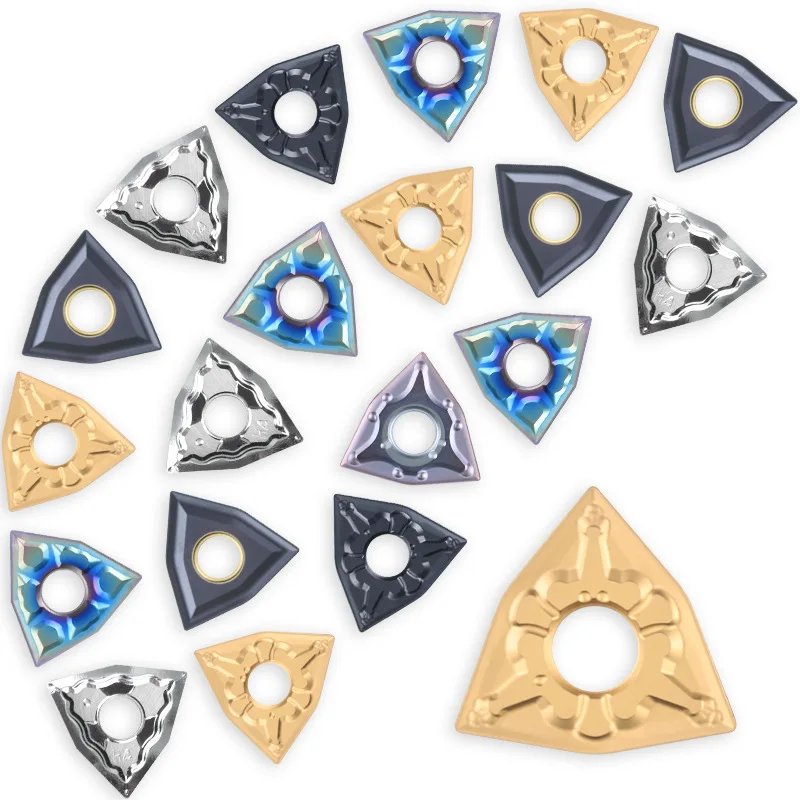

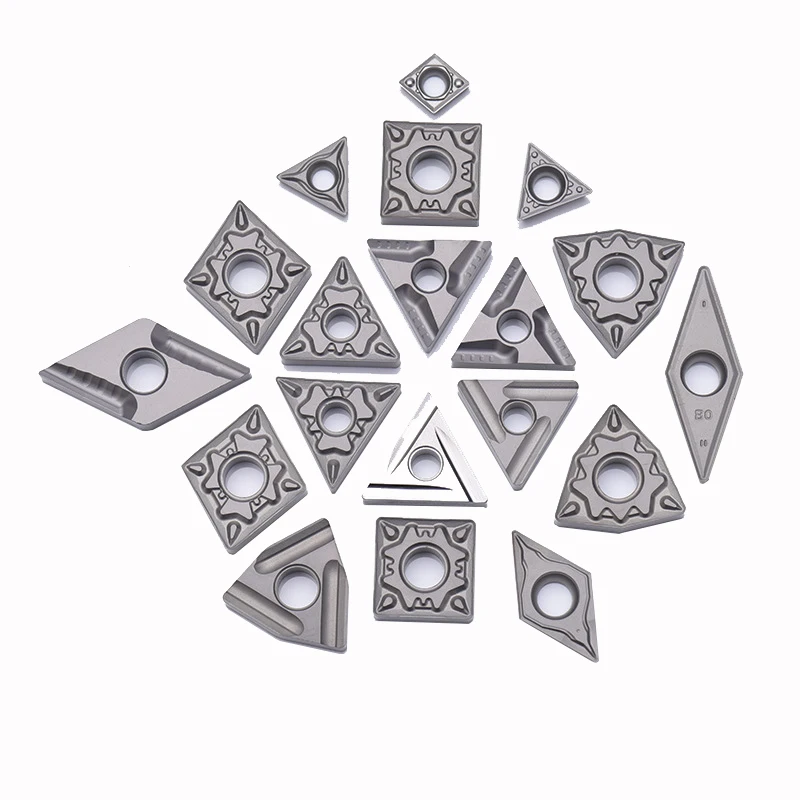

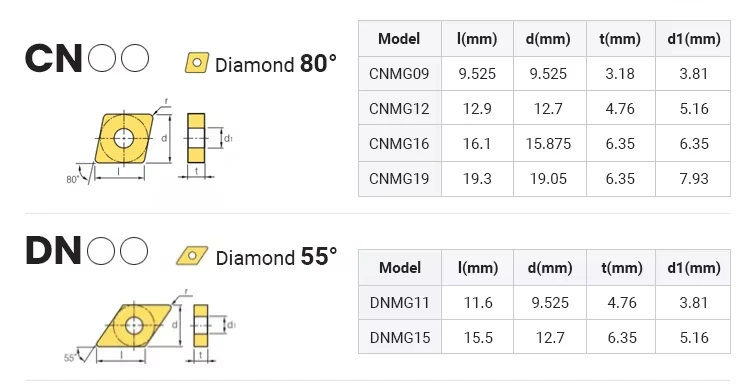

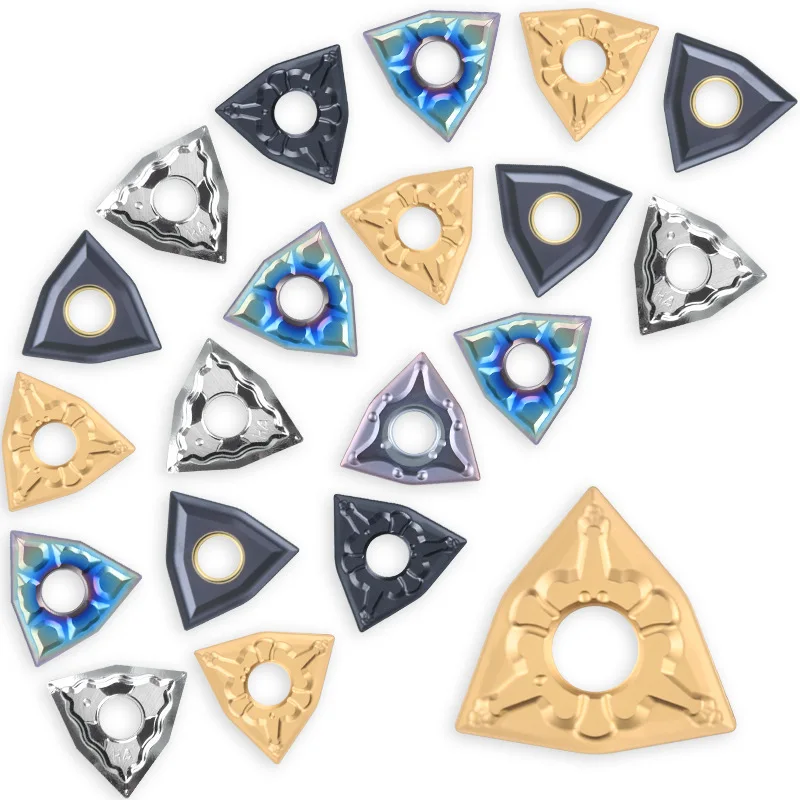

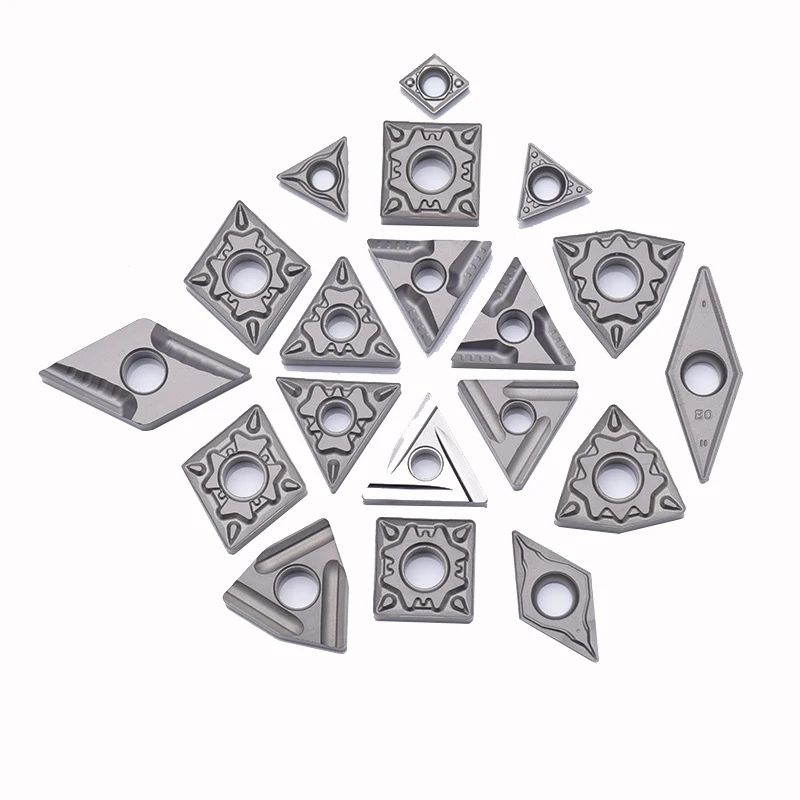

Производители токарных вставок APMT CNMG DNMG SNMG TNMG VNMG WNMG фрезерные Вставки для токарного станка твердосплавная вставка CNC

- Категория: >>>

- Поставщик: Henan Saisu Diamond Products Co. Ltd.Henan Ltd.

Сохранить в закладки 1601260175912:

Описание и отзывы

Характеристики

Products Show

WHY CHOOSE US

SHIPPING:

1.we could ship by Commercial Express,like UPS,DHL,FedEx,Aramex,we could also ship byair/by sea/by land as your request.

2. A tracking number will be updated within two working days once your order is shipped.

3. We are not responsible for any customs charges, taxes,or fee. For any details please contact your local customs office.

4. If you have not received your parcel, please contact us immediately for help. We will reply the email within 24 hours.

NOTICE: Holidays and weekends are not included in working days.

Похожие товары

Карбидные CNC режущий инструмент DNMG DNMG150408-HS PC9030 твердосплавный токарные вставки

2,90-3,16 $

LNMU0303ZER-ML AH3035 Япония tungaloys вставка лнму 03 фрезерный станок с хорошей ценой

6,10-6,40 $

Карбидные Токарные Вставки Wnmg080408 для обработки нержавеющей стали

10 шт. Угловой блок прецизионный

EATH инструменты прецизионные режущие пластины из нержавеющей стали производитель карбидный TPGH080201L-F материал режущий инструмент

1,62-1,98 $

Высокая износостойкость режущий инструмент карбид вольфрама вращающая вставка CCMT09T304 CCMT060204 мини-токарный станок для металла

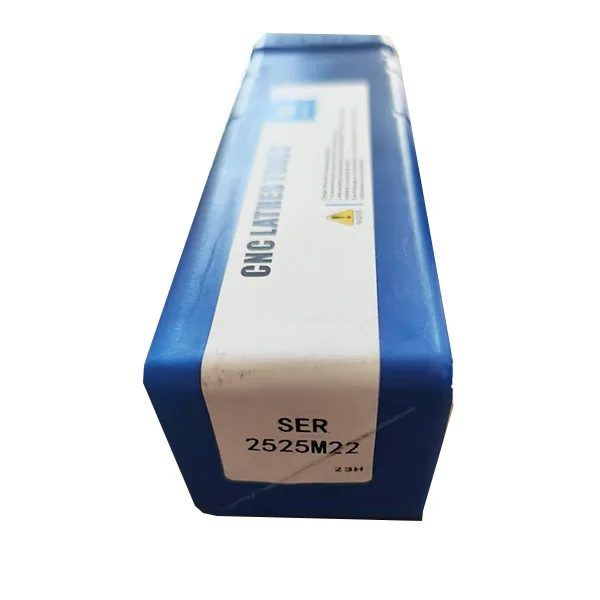

Внешняя резьба ЧПУ резак бар SER2525M16 SEL2525M16

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $