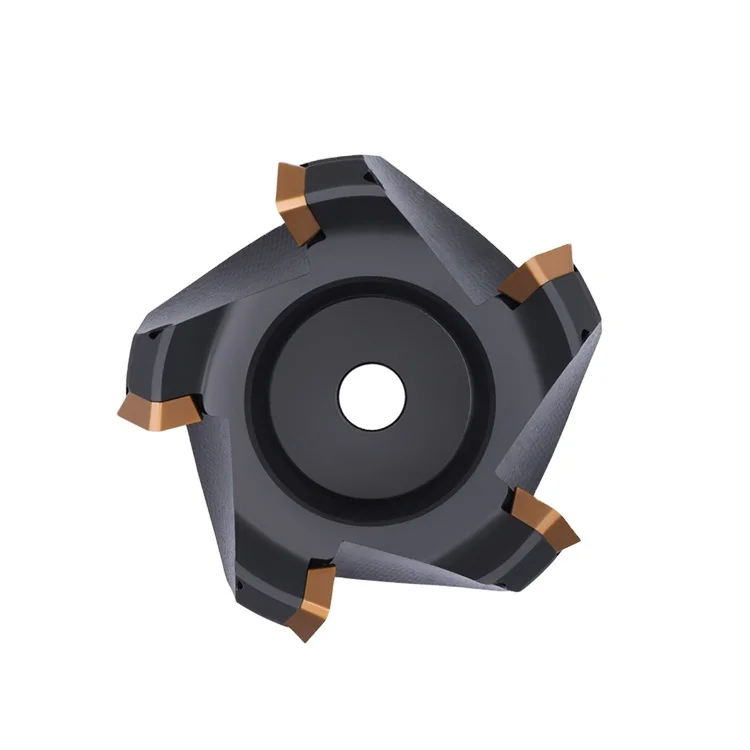

KM12 алюминиевая фрезерная головка обрабатывающие центры 45 градусов легкие фрезерные инструменты подходит для твердосплавных вставок SEKT1204

- Категория: >>>

- Поставщик: Wenzhou Baifu Trade Co. Ltd.Wenzhou Ltd.

Сохранить в закладки 1601260868913:

Описание и отзывы

Характеристики

- High-quality aluminum alloy: Made of high-quality aluminum alloy material, while ensuring strength, it greatly reduces the weight of the cutter head. This is of great significance for improving processing efficiency, reducing equipment energy consumption, and facilitating operation and handling.

- Good corrosion resistance: Aluminum alloy has better corrosion resistance and can maintain stable performance in various processing environments and prolong the service life of the cutter head.

- Precise structural design: The carefully designed cutter head structure ensures the installation accuracy and stability of the cutting tool. Reasonable cutter tooth layout and angle design can achieve efficient cutting processing and improve processing quality and efficiency.

- Unique characteristics of KM12 model: It may have specific size specifications, tool installation methods or other special designs to meet different processing needs and application scenarios.

- Aerospace field: In the processing of aerospace parts, the lightweight feature of the AL KM12 aluminum body milling cutter head is particularly important. It can be used to process various aluminum alloy structural parts such as aircraft fuselages and wings to meet the strict requirements of the aerospace field for high precision and lightweight.

- Automobile manufacturing industry: For the processing of automobile aluminum alloy parts, this cutter head can efficiently complete various milling tasks. For example, processing automobile engine blocks, wheels and other components to improve the quality and efficiency of automobile manufacturing.

- Electronic equipment manufacturing: In the processing of electronic equipment casings and parts, the AL KM12 aluminum body milling cutter head can achieve high-precision cutting processing to meet the high requirements of electronic equipment for appearance and dimensional accuracy.

Our professional experience and service quality

Wenzhou Shengang CNC Tool Co., Ltd. has been engaged in the CNC tool industry for 10 years. We have a manufacturing and processing site area of 600 square meters, a warehouse area of 1000 square meters, and an office area of 600 square meters. The office area also provides comprehensive hardware tool products. Simultaneously possessing rich experience in customer service both domestically and internationally. Our main products include high-speed steel tool holders, damping tool holders, alloy drill bits, alloy blades, tungsten steel milling cutters, machining center tools, etc. Non innovation welcomes major friends, peers, and end customers to choose to cooperate with us. We will strive to meet the needs of every customer.

1.Are you a factory or a trading company?

Yes, we have a factory And we also have 10 years of professional manufacturing experience. In addition, we also make some trading.

2.Is there a free delivery service?

We do not offer free delivery services, but if you purchase a sufficient quantity of products, we will offer you some corresponding discount prices.

3.Can you send the product to our freight forwarder in China?

Yes, if you have a freight forwarder in China, l would be happy to send the product to them.

4. Do you do OEM?

Yes, we do.We can customize according to your needs.

5.What is the delivery time?

Delivery time varies depending on size and quantity. Usually 3 to 7 days. We can tell the exact inventory state if you need.

Похожие товары

ZANHO Cadcam 55 Hrc 2 Флейта 1 5 длинный шариковый носик плоский Соединительный резак карбидная Концевая фреза с длинным шеей

SMP трехсторонняя головка MillingCutterhead CNC фрезерная MPHT06 08 12

Высококачественный профиль шестерни KM12 45 ° специальный резак для обработки металла фрезерная головка Cnc вставка продажи

Фреза по металлу с твердосплавным покрытием

Фрезерная режущая головка KF CNC 400R прямоугольная Indexble

Высокополированный ЧПУ HRC 45 55 3 фрезы из карбида алюминия фреза для алюминиевого профиля

Лезвие циркулярной пилы TCT толстое лезвие сплава 300 мм 96 т Деревообрабатывающие инструменты

Новые поступления

Новинки товаров от производителей по оптовым ценам