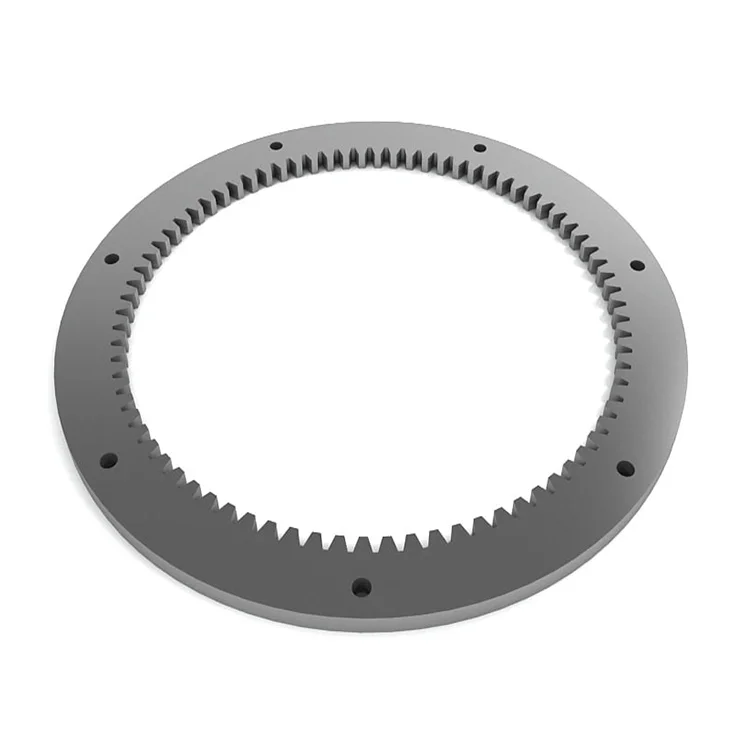

Высокоточный металлический винтовой зубчатый Вал более длительный срок службы стальные шестерни для энергетики и горнодобывающей промышленности

- Категория: >>>

- Поставщик: Qingdao Senbaoxiang Trading Co. Ltd.

Сохранить в закладки 1601261787760:

Описание и отзывы

Характеристики

High-Precision Metal Helical Gear Shaft Longer Service Life Steel Gears For Energy & Mining

1. Main Material

Stainless Steel | SS201,SS301,SS303, SS304, SS316, SS416 etc. |

Steel | Mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

Copper | C11000,C12000,C12000, C36000 etc. |

Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

Iron | A36, 45#, 1213, 12L14, 1215 etc. |

Plastic | ABS, PC, PE, POM, Nylon, PP, Peek etc. |

2. Surface Treatment

Stainless Steel | Polishing, Passivating, Sandblasting, Laser engraving |

Steel | Zinc plating, Oxide black, Nickel plating, Chrome platingk, Carburized, Powder Coated |

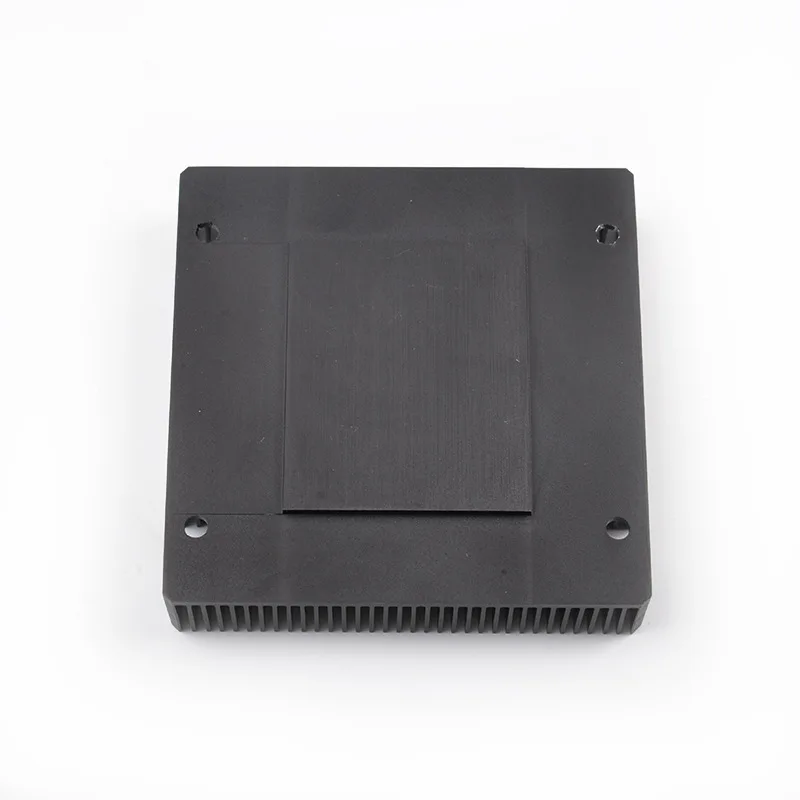

Aluminum parts | Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film,Brushing,Polishing |

Plastic | Plating gold (ABS), Painting, Brushing (Acylic), laser engraving |

3. Other Information

Technology | Investment Casting,Precision Casting,Clay Sand Casting,Resin-bonded Sand Casting,Resin Sand Casting,Resin Coated Sand Casting,Shell Mould Casting,Precoated Sand Casting,Silica Sol Lost Wax Investment Casting,Lost Foam Casting Process,Waterglass Casting,Soluble Glass Casting, Die Casting,Hot Forged,Cold Forged,etc. |

Machining | Drilling, Reaming and tapping CNC Turning machining CNC Milling machining Wire EDM |

Process | Molds,Casting,Deburring,Machining,Surface Treatment,Packing |

Weight | Available from 0.1Kg-120Kg |

Standard | ISO,GB,DIN,JIS,ANSI,BSW,ASTM,ASME,BS,API,EN |

Casting Tolerance | CT4-CT8 |

Machining Tolerance | +/-0.02mm |

Drawing | Required, or provide the samples |

Quality Assurance | 100% QC steps inspection before shipment |

Certification | ISO9001: 2015,TUV |

File Formats | PDF, DWG, DXF, IGES, STEP, XT, etc |

Application | Glass Ribs, Glass Clamps, Vehicle Parts, LED housing,Support Bracket, Machine Parts, Motorcycle Spare Parts, Agricultural Machinery Parts, Engineering Machinery Parts, Engine Components, Aluminum Generator Spare Parts, Engine Bushing, Automobile Radiator Accessories, Power Generation Industries Components, Engine Blocks, Regulator Housing, Clapboard, Crane Spare Parts, General Mechanical Parts, Medical Devices Components, Scaffold Spare Parts, National Defense Components, Construction Spare Parts, Mining Mechanical Parts, Material Handling Spare Parts, LED Cover, LED HeatSink, Water Pump Spare Parts, Light Cases, Water Pump Spare Parts Components, General Industrial Equipment Components, Baffle Plate, Machine Bases, Automobile Suspension Spare Parts, Motor Pedestal, Truck Parts, ect. |

Packaging | Carton Box/Wooden Box/Steel Pallet or as per customer’s requirement |

Delivery time | 35-45 days for mass production |

Port | Qingdao Port and Qingdao Airport |

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

Testing Equipment

Our company also has the most advanced and complete inspection equipment in the casting industry, including Spectrometer, Metallographic Microscope, Tension Tester, Low Temperature Tester, X-ray Tester, MPT, UT, CMM, Video Measurement Machine and so on. With these advanced facilities & instruments, we are able to supply the most precise finished products to our customers, and make products meeting their overall inspection requirements on chemical composition, mechanical properties, non-destructive testing and high precise dimensional inspections.

1. More than 15 years casting and machining operation experience

2. Competitive Price, fast delivery and strict inspection.

3. Nearest to Qingdao Port and Qingdao International Airport.

4. Full engineering support .

5. Professional at OEM & ODM parts .

6. Excellent after sales service.

7. We provide one-stop service, including mold and assembly.

8. Strict quality control standards with a highly qualified inspection department.

9. Small quality are acceptable.

10. Short production lead time.

Our company established in 2006, after many years development becomes a professional company engaged in stainless steel parts, steel parts, aluminium parts, marine hardware, construction parts, machinery parts research and development, production, sales, service in one company, we have a series of advanced equipment, including CNC machining center, CNC milling machine, CNC lathing machine, salt spray test, spectrometer test, etc. Our company has convenient transportation to Qingdao port and Qingdao airport. Our experienced teams can help you to solve all your different requirements to ensure the satisfaction of our customers.

Sand Casting Workshop

Investment Casting Workshop

Sheet Metal Workshop

Machining Workshop

Powder Coating Workshop

We are professional at independent development and design. Our engineers are skilled at AUTO CAD, UG, PRO ENGINEER, SOLID WORKS and other 2D & 3D software. We are able to design, develop, produce and deliver your PO according to your drawings, samples or just an idea.

Our Team

We have an experienced team working together, some of them already working for more than 12 years, we can guarantee our quality from raw material to the final products all according to our customer’s requirements.

Customer Visit

Manufacturing Process

Customer Review

Packaging & Shipping

Our products are all packed in wooden cases to ensure zero damage. If customers have specific requirements for the packaging, we will gladly accommodate. The products will be sent to you on time and we will arrange everything from the initial consultation to the delivery of your chosen port anywhere the world. We can also customize the packing method according to customers' needs. Suitable for seaway transportation.

Packing Details:

1) Inner packing: Plastic/paper wrap, bubble bag, PE foam, EPE cotton, PP bag etc.

2) Outer packing: carton box, wooden case, Steel pallet, etc.

3) As per customer's requirement

1.How can I get the quotation?

Please give us your drawing, quantity, weight and material of the product.

2.If you don't have the drawing,can you make drawing for me?

Yes, we are able to make the drawing of your sample duplicate the sample.

3.When can I get the sample and your main order time?

Sample time: 15-30 days after start to make mold.

Order time: 35-40 days, the accurate time depends on product.

4.What is your payment method?

Tooling: 50% T/T in advance, after sample approved pay balanced.

Order time: 30% deposit, 70% against copy of B/L.

5.Which kind of file format you can read?

PDF, IGS, DWG, STEP, JPG, PNG, MAX

6.What is your surface treatment?

Including: powder coating, sand blasting, painting, polishing, acid pickling, anodizing, enamel, zinc plating, hot-dip galvanizing, electrophoresis, chrome plating.

7.What is your way of packing?

Normally we pack goods according to customers' requirements.

If you are interested in our products, welcome to contact us.

steel bevel pinion gear bevel pinion gear/bevel gear steel, Steel Spur Gear/Carbon Steel Spur Gear, Custom Manufacturer Steel Straight Bevel Gear Spiral Bevel Gear, Small Spiral steel straight bevel gear with keyway, gear machining factory direct sale large steel 10 module big gear, Cheap steel 2000 mm helical rack gear for plasma machines, Carbon Steel Straight Bevel Gear

Похожие товары

Изготовление на заказ, колесные шестерни, стальные шестерни, шестерня из нержавеющей стали, спиральная коническая шестерня

Прямая Продажа с завода, нейлоновая Шестерня из нержавеющей стали, Винтовая шестерня из нержавеющей стали для оборудования автоматизации

Гибкая длина резки 6063 T5 экструдированный пассивный радиатор экструзионный 113(W)* 45(H) мм

Гибкая длина резки 6063 T5 экструдированный пассивный радиатор экструзионный 113(W)* 45(H) мм

ASME Сертифицированный санитарный прямолинейный трубчатый конденсаторный теплообменник из нержавеющей стали с ЧПУ

Направляющая из нержавеющей стали с ЧПУ

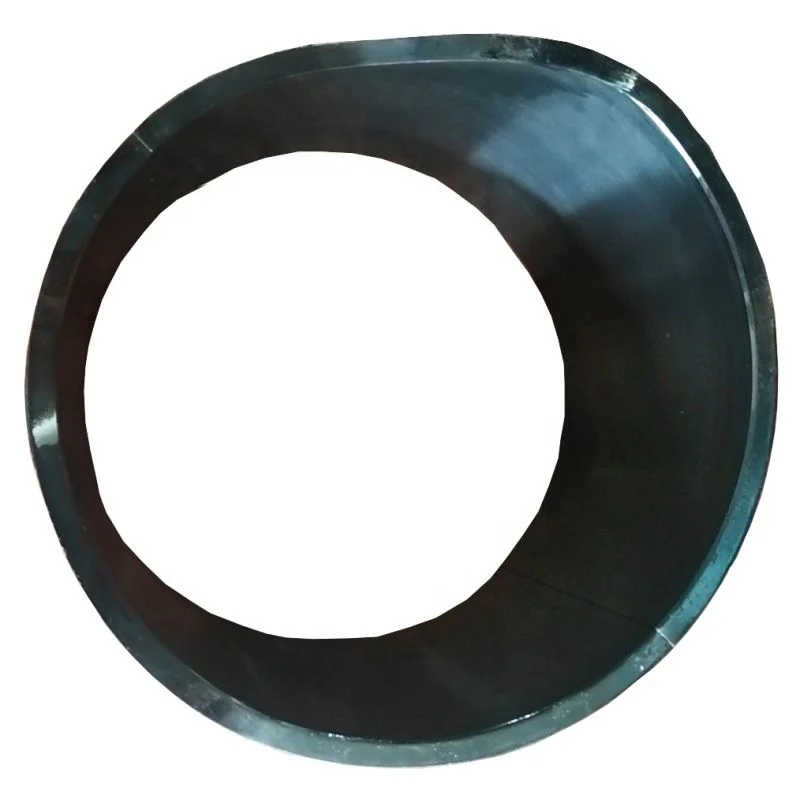

Промышленное оборудование, высокоскоростные вращающиеся машины, автомобильная сборка и кольцевая направляющая MH-TL-DG01 для медицинской промышленности

Новые поступления

Новинки товаров от производителей по оптовым ценам