Навозная жижа для дорожного моста

- Категория: >>>

- Поставщик: Guangxi Xinhuilian Building Materials Co. Ltd.Guangxi Ltd.

Сохранить в закладки 1601261982402:

Описание и отзывы

Характеристики

Product Overview

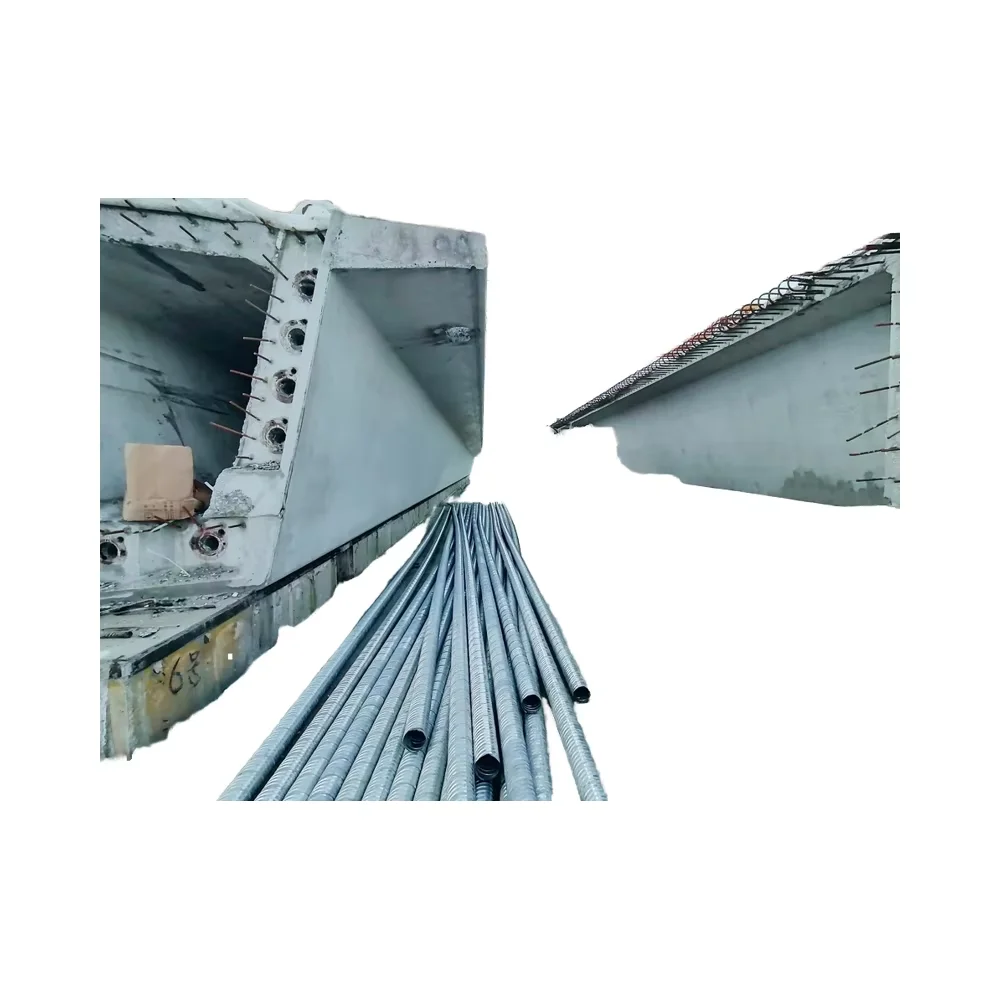

Highway bridge slurry is a special product for post-tensioning pre-stressing pipe (hole) slurry construction, which is optimally formulated from a variety of high-quality cement-based materials and high-performance additives. This material has excellent fluidity, slurry stability, good filling degree, adjustable setting time, non-shrinkage, micro-expansion, high strength and does not contain harmful substances to the reinforcement and other characteristics.

The use of aperture slurry can ensure the bond between prestressing tendons and concrete, so that the prestressing reinforcement can effectively transfer the force, and also provide protection to the prestressing tendons, preventing them from corrosion, thus improving the durability and safety of the structure.

In addition, the aperture slurry also has a low water-to-cement ratio, high fluidity, suitable setting time, strong stability, no water secretion, early strength, high strength, high fracture resistance, micro-expansion properties and non-shrinkage, etc., and these characteristics make it widely used in the construction industry, especially in a variety of railroads, highway post-tensioning pre-stressed bridges, such as aperture slurry projects!

The use of aperture slurry can ensure the bond between prestressing tendons and concrete, so that the prestressing reinforcement can effectively transfer the force, and also provide protection to the prestressing tendons, preventing them from corrosion, thus improving the durability and safety of the structure.

In addition, the aperture slurry also has a low water-to-cement ratio, high fluidity, suitable setting time, strong stability, no water secretion, early strength, high strength, high fracture resistance, micro-expansion properties and non-shrinkage, etc., and these characteristics make it widely used in the construction industry, especially in a variety of railroads, highway post-tensioning pre-stressed bridges, such as aperture slurry projects!

Product Description

groutProduct name | Highway bridge slurry |

Application | 1 Post-tensioned prestressed bridge aperture grouting: various railroad and highway post-tensioned prestressed bridge aperture grouting, large prestressed structure aperture grouting, and various concrete structure joints stop leakage grouting. It is used in the construction of prestressed concrete bridges to ensure effective stress transfer between prestressing bundles and concrete structures, providing solid support and reliable reinforcement. 2: Curtain grouting and anchoring grouting: in building foundation and geotechnical engineering, it is used to reinforce the soil and improve the bearing capacity and stability of the foundation. 3:Filling and repairing of voids and cavities: used to repair voids and cavities in concrete structures and improve the integrity and strength of the structure. 4:Stop leakage grouting at joints of various concrete structures: to prevent water penetration and improve the waterproof performance of the structure. 5:Grouting of equipment foundation and beam-column joints: used for reinforcement of equipment foundation and connection of beam-column joints to improve structural integrity and safety. 6:Engineering Emergency Repair and Bolt Anchoring: In emergency repair and reinforcement projects, it quickly and effectively improves the strength and stability of the structure. 7:Pore Grouting for High Strength Steel Prestressed Concrete Members: Used for filling the pores of high strength steel prestressed concrete members to improve the compactness and strength of the structure. 8:Bridge Reinforcement: It is used for reinforcing roads and bridges to improve their bearing capacity and service life. |

Design Style | Modern |

Brand Name | XIN HUI LIAN |

Model Number | C50 |

Packaging | Fiber bag with built-in moisture-proof inner bag, kraft paper bag |

0.26Water-binder ratio | 0.26~0.28 |

Material | About 1700kg/m³ |

Application scenario

1 Post-tensioned prestressed bridge aperture grouting: various railroad and highway post-tensioned prestressed bridge aperture

grouting, large prestressed structure aperture grouting, and various concrete structure joints stop leakage grouting. It is used

in the construction of prestressed concrete bridges to ensure effective stress transfer between prestressing bundles and concrete

structures, providing solid support and reliable reinforcement. 2: Curtain grouting and anchoring grouting: in building foundation

and geotechnical engineering, it is used to reinforce the soil and improve the bearing capacity and stability of the foundation.

3:Filling and repairing of voids and cavities: used to repair voids and cavities in concrete structures and improve the integrity

and strength of the structure. 4:Stop leakage grouting at joints of various concrete structures: to prevent water penetration and

improve the waterproof performance of the structure. 5:Grouting of equipment foundation and beam-column joints: used for

reinforcement of equipment foundation and connection of beam-column joints to improve structural integrity and safety.

6:Engineering Emergency Repair and Bolt Anchoring: In emergency repair and reinforcement projects, it quickly and effectively

improves the strength and stability of the structure. 7:Pore Grouting for High Strength Steel Prestressed Concrete Members: Used

for filling the pores of high strength steel prestressed concrete members to improve the compactness and strength of the

structure. 8:Bridge Reinforcement: It is used for reinforcing roads and bridges to improve their bearing capacity and service

life.

grouting, large prestressed structure aperture grouting, and various concrete structure joints stop leakage grouting. It is used

in the construction of prestressed concrete bridges to ensure effective stress transfer between prestressing bundles and concrete

structures, providing solid support and reliable reinforcement. 2: Curtain grouting and anchoring grouting: in building foundation

and geotechnical engineering, it is used to reinforce the soil and improve the bearing capacity and stability of the foundation.

3:Filling and repairing of voids and cavities: used to repair voids and cavities in concrete structures and improve the integrity

and strength of the structure. 4:Stop leakage grouting at joints of various concrete structures: to prevent water penetration and

improve the waterproof performance of the structure. 5:Grouting of equipment foundation and beam-column joints: used for

reinforcement of equipment foundation and connection of beam-column joints to improve structural integrity and safety.

6:Engineering Emergency Repair and Bolt Anchoring: In emergency repair and reinforcement projects, it quickly and effectively

improves the strength and stability of the structure. 7:Pore Grouting for High Strength Steel Prestressed Concrete Members: Used

for filling the pores of high strength steel prestressed concrete members to improve the compactness and strength of the

structure. 8:Bridge Reinforcement: It is used for reinforcing roads and bridges to improve their bearing capacity and service

life.

Features

1:Enhance the structural force: the compression slurry can enhance the mechanical properties of concrete structure, improve the strength and stability of the structure.

2:Improvement of crack resistance: Pressure slurry can improve the crack resistance of concrete structure, reduce the generation and expansion of cracks.

3:Improvement of waterproofing: Pressure slurry can improve the waterproof performance of concrete structure, preventing water penetration and erosion.

4:Material saving: Compared with traditional reinforcement methods, compression slurry can save a lot of materials and reduce the project cost.

5:High durability: The whole is made of inorganic material proportioning, with high durability, no aging, and no rusting of steel reinforcement.

6:Micro-expansion: with micro-expansion characteristics, it can reach high strength in a short time, ensuring that the slurry in the borehole is more dense.

7:High filling property: with high filling property, it can be used in one-time slurry project construction, and the slurry in the borehole is dense.

8:Anti-corrosion and anti-corrosion: It does not contain harmful substances to steel reinforcement, and has the characteristics of anti-corrosion and anti-corrosion to ensure the quality of the project.

9:Convenient operation: it can be used on the spot by adding water, no need to worry about the dosage problem, easy to operate.

2:Improvement of crack resistance: Pressure slurry can improve the crack resistance of concrete structure, reduce the generation and expansion of cracks.

3:Improvement of waterproofing: Pressure slurry can improve the waterproof performance of concrete structure, preventing water penetration and erosion.

4:Material saving: Compared with traditional reinforcement methods, compression slurry can save a lot of materials and reduce the project cost.

5:High durability: The whole is made of inorganic material proportioning, with high durability, no aging, and no rusting of steel reinforcement.

6:Micro-expansion: with micro-expansion characteristics, it can reach high strength in a short time, ensuring that the slurry in the borehole is more dense.

7:High filling property: with high filling property, it can be used in one-time slurry project construction, and the slurry in the borehole is dense.

8:Anti-corrosion and anti-corrosion: It does not contain harmful substances to steel reinforcement, and has the characteristics of anti-corrosion and anti-corrosion to ensure the quality of the project.

9:Convenient operation: it can be used on the spot by adding water, no need to worry about the dosage problem, easy to operate.

Performance parameters of grout

Usage Method

1: Flushing the hole

The hole should be flushed with pressure water before slurrying, in order to exclude the powder slag and other debris in the hole, and ensure that the hole is smooth, after flushing, use the air compressor to blow away the water in the hole, but keep the hole wet and make the cement slurry combine well with the hole wall, in the process of flushing, such as water bubbling and leakage phenomenon, it should be timely plugging the loophole to deal with it.

2: Cement paste mixing

① cement paste should have enough fluidity, fluidity of 15:~ 20mm to meet the grouting requirements.

② The water used for water and gray slurry should be clean water, not containing substances harmful to cement or prestressing steel strand.

3: Mixing of cement slurry:

The mixing ratio of cement slurry is determined by trial mixing before mixing, or it can be determined according to the previous mixing ratio retest. For the mixing of cement slurry, firstly add water into the mixer, turn on the mixer and then add the pressurized slurry, and the material measurement should be based on the weight of the pressurized slurry to calculate the water dosage. The mixing time should ensure that the cement slurry is evenly mixed, which generally takes about 3min. During the grouting process, the mixing of cement slurry should be uninterrupted, and when the grouting process stops for a short period of time, the cement slurry should be allowed to circulate in the mixer and the grouting machine, so as to prevent blocking the pipeline and the switching valves after precipitation.

4: After the prestressing strand is tensioned, the aperture should be grouted as early as possible and in time. Aperture grouting is to use grouting pump to press and pour cement slurry into the prestressing tendon aperture, so as to fill the gap between prestressing strand and aperture, and let the prestressing strand and concrete firmly bond as a whole. The aperture is grouted in time, and the grouting process: the grouting generally adopts the piston grouting pump, and the pressure of grouting is subject to ensure that the cement slurry pressed into the hole is compact, and the maximum pressure of grouting should be controlled at 0.5-0.7Mpa, and the pressure should be appropriately increased in the case of one-time grouting, but the maximum pressure should not be more than 1.0Mpa.

5: Grouting should be carried out slowly, evenly, without interruption, the beginning of the pressure should be small, gradually increase the pressure, grouting should be achieved at the other end of the aperture vent hole full and out of the thick slurry (should be the same consistency with the provisions of the cement slurry) until, and then use the bolts plug plug the slurry outlet. In order to ensure that the orifice is full of mortar, after each orifice is grouted to the maximum pressure, a stabilized pressure period, which is generally not less than 0.5Mpa, should be maintained, and this stabilized pressure period should not be less than 2min. close the valve of the inlet, and the grouting machine will return to the grouting machine, and then dismantle the connecting joints and clean up instantly after the cement slurry is solidified.

:6: In order to check the actual density of the cement slurry in the borehole, the compactness of the slurry should be sampled from the inspection hole after the slurry compression, if it is not solid it should be dealt with in time, and the method of treatment can be used for secondary grouting. At the same time of mixing cement slurry, make standard test block, after the same conditions as the beam maintenance. Compressive strength of cement slurry: the strength of cement slurry shall not be less than M30 grade, and the test block of cement slurry shall be made by cubic mortar test mold with side length of 70.7mm.

The hole should be flushed with pressure water before slurrying, in order to exclude the powder slag and other debris in the hole, and ensure that the hole is smooth, after flushing, use the air compressor to blow away the water in the hole, but keep the hole wet and make the cement slurry combine well with the hole wall, in the process of flushing, such as water bubbling and leakage phenomenon, it should be timely plugging the loophole to deal with it.

2: Cement paste mixing

① cement paste should have enough fluidity, fluidity of 15:~ 20mm to meet the grouting requirements.

② The water used for water and gray slurry should be clean water, not containing substances harmful to cement or prestressing steel strand.

3: Mixing of cement slurry:

The mixing ratio of cement slurry is determined by trial mixing before mixing, or it can be determined according to the previous mixing ratio retest. For the mixing of cement slurry, firstly add water into the mixer, turn on the mixer and then add the pressurized slurry, and the material measurement should be based on the weight of the pressurized slurry to calculate the water dosage. The mixing time should ensure that the cement slurry is evenly mixed, which generally takes about 3min. During the grouting process, the mixing of cement slurry should be uninterrupted, and when the grouting process stops for a short period of time, the cement slurry should be allowed to circulate in the mixer and the grouting machine, so as to prevent blocking the pipeline and the switching valves after precipitation.

4: After the prestressing strand is tensioned, the aperture should be grouted as early as possible and in time. Aperture grouting is to use grouting pump to press and pour cement slurry into the prestressing tendon aperture, so as to fill the gap between prestressing strand and aperture, and let the prestressing strand and concrete firmly bond as a whole. The aperture is grouted in time, and the grouting process: the grouting generally adopts the piston grouting pump, and the pressure of grouting is subject to ensure that the cement slurry pressed into the hole is compact, and the maximum pressure of grouting should be controlled at 0.5-0.7Mpa, and the pressure should be appropriately increased in the case of one-time grouting, but the maximum pressure should not be more than 1.0Mpa.

5: Grouting should be carried out slowly, evenly, without interruption, the beginning of the pressure should be small, gradually increase the pressure, grouting should be achieved at the other end of the aperture vent hole full and out of the thick slurry (should be the same consistency with the provisions of the cement slurry) until, and then use the bolts plug plug the slurry outlet. In order to ensure that the orifice is full of mortar, after each orifice is grouted to the maximum pressure, a stabilized pressure period, which is generally not less than 0.5Mpa, should be maintained, and this stabilized pressure period should not be less than 2min. close the valve of the inlet, and the grouting machine will return to the grouting machine, and then dismantle the connecting joints and clean up instantly after the cement slurry is solidified.

:6: In order to check the actual density of the cement slurry in the borehole, the compactness of the slurry should be sampled from the inspection hole after the slurry compression, if it is not solid it should be dealt with in time, and the method of treatment can be used for secondary grouting. At the same time of mixing cement slurry, make standard test block, after the same conditions as the beam maintenance. Compressive strength of cement slurry: the strength of cement slurry shall not be less than M30 grade, and the test block of cement slurry shall be made by cubic mortar test mold with side length of 70.7mm.

Packing & Delivery

Company Profile

Certifications

FAQ

Q1:Are you a factory?

A:Yes,we are a factory,but not just a factory,as we have sales team,our own offices,

professioners,masters and doctors,and they all can help the buyers and cooperative

partners to decide which products are the best choices for them,and all your require-

ments and inquires will be replyed in time.

Q2:Could you send me all your catalogues and price lists?

A:As we have many items,please inform us the items,size and packages you interested

in, so that we are capable to offer the price lists to you for your reference .

Q3:Could you send me some samples?

A:Of course we're capable of sending you some free samples for your evaluation by air

for speed increases.And it's free for the delivery charge while the weights under 5 kg ,

but we are afraid you should pay for the delivery charge if the total weight exceeds 5kg.

Q4:What's your Delivery Time?

A:In general, the delivery time is within 7 days after payment.We will make the delivery

as soon as possible with the guaranted quality.

Q5:What is the convenient way to pay?

A:L/C , T/T are accepted,and if you have a better idea , please feel free to share with us.

Q6:Which type of shipping would be better?

A:Generally,in consideration of the cheap and safe superiorities of sea transportation,we

advice to make delivery by sea.What more, we respect your views of other transportation

as well.

A:Yes,we are a factory,but not just a factory,as we have sales team,our own offices,

professioners,masters and doctors,and they all can help the buyers and cooperative

partners to decide which products are the best choices for them,and all your require-

ments and inquires will be replyed in time.

Q2:Could you send me all your catalogues and price lists?

A:As we have many items,please inform us the items,size and packages you interested

in, so that we are capable to offer the price lists to you for your reference .

Q3:Could you send me some samples?

A:Of course we're capable of sending you some free samples for your evaluation by air

for speed increases.And it's free for the delivery charge while the weights under 5 kg ,

but we are afraid you should pay for the delivery charge if the total weight exceeds 5kg.

Q4:What's your Delivery Time?

A:In general, the delivery time is within 7 days after payment.We will make the delivery

as soon as possible with the guaranted quality.

Q5:What is the convenient way to pay?

A:L/C , T/T are accepted,and if you have a better idea , please feel free to share with us.

Q6:Which type of shipping would be better?

A:Generally,in consideration of the cheap and safe superiorities of sea transportation,we

advice to make delivery by sea.What more, we respect your views of other transportation

as well.

Похожие товары

Высокое качество строительная сосновая древесина оптовая цена коммерческая фанера стандарт AS1577

475,00-490,00 $

Sentry Box 20-футовые сборные дома расширяемый контейнерный дом крошечная вилла

3 800,00-5 699,00 $

Высокоэффективный Магнитный смягчитель воды для сельскохозяйственного орошения полей

8 900,00-9 000,00 $

Подгонянный новый бренд Тонкий минеральный порошок для высокопрочного бетона

130,00-185,00 $

Подвесная лампа со стеклянным шариком Белый 50 современный энергосберегающий круглый стеклянный шар люстра металлические и стеклянные 500 наборы 1000

15,00 $

Полигона многоцветковая эссенция влажное мягкое питательное Мыло для волос

1,20 $

Оцинкованная железная проволочная сетка с ПВХ покрытием габион машина подпорные стенки в Южной Африке

5,30-25,10 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $