Индивидуальные бытовые товары инструменты для литья под давлением прочные литьевые формы изготовленные из ПВХ TPR ABS TPU PP PC

- Категория: >>>

- Поставщик: Sando Technology Co. Ltd.

Сохранить в закладки 1601263262854:

Описание и отзывы

Характеристики

Dongguan Sando Technology Co., Ltd.

Our Service

>> We provide one-stop service.

Can do from product design, mould design, mould making, plastic part injection molding to Logo printing, assembly, package, and shipping.

>> Free design & modification service.

Just sent to us a part sample or your sketch idea. our designer can provide free product design work. we also provided free optimization suggestions & modification in DFM report.

>> Saving your mould fee way here.

Once order quantity reache some of negotiation amount, mold fee can be refund to you.

>> Urgent lead-time mould.

For certain urgent mould request, we can complete T0 samples within 10 days and delivery.

>> Our team like challenging complex and difficult.

Help customers many projects successful, help losts of customers projects from ideas come to true.

>>We treat every customer attentively and considerately.

No matter big order or small projects, customer satisfaction is always our persistent pursuit. we appreciate and cherish every your business chance! with our accurate machining, competitive cost and good impressive customer service, let's start from an inquiry. looking forward to cooperation with you for long-term business!

| Company Name | Dongguan Sando Technology Co., Ltd. |

| Place of Origin | Dongguan, Guangdong, China. |

| Business Type | Manufacturer |

| Product Description | Custom parts plastic injection molding and Injection mould. |

| Main Service | Product design,Plastic injection mold,Medical part mold,2K injection mold,Silicone rubber mold,Die casting,Prototype,CNC machining. |

| Plastic Material | ABS, PE, PP, HDPE, LDPE, LLDPE, PVC, GPPS, TPU, TPR, HiPS, AS(SAN), PMMA,PET, PBT, PA66, PC, POM, PPO, PPS, PU, PS, PTFE. |

| Design software | Solidworks,UG, Creo, AutoCAD, Mouldflow, CATIA, PS, AI with igs/.stp/.x_t/.step/.prt/.stl/.sldprt/.dwg/.dxf formats. |

| Mould Tolerance | +/-0.01mm. |

| Mould Life | 10-300K shots. |

| Mould Cavity | Single cavity, Multi-cavities. |

| Runner System | Cold runner and Hot runner. |

| GateType | Pinpoint Gate, Edge Gate, Fan gate, Sub Gate, Film Gate, Valve Gate, Sprue Gate. |

| Mould Steel | P20/738H/NAK80/S136/1.2344/H13/8407/SKD61 |

| Mould Base | LKM, HASCO or Equivalen standard. |

| Sureface Treatment | Polishing, High glossy, Texture, Plating, Anodizing, Brushing, Spray Painting, Chroming, Silk Screening, Water Transfering, Laser engraving, Sanblasting. |

| Facilities | Imported CNC equipment, EDM machines, Imported mirror wire cutting machines, High-speed precision engraving machines, Laser cutting machines, Sodick slow threading machines, Precision grinders, Plastic injection molding machines,Double color injection machines,etc. |

| Color match | White, Black, Red, Blue, Green, purple, Yellow..etc. and do color match according to customer's requirement with PANTONE or RAL. |

| Injection Machies Capacity | 80T, 120T, 160T, 250T, 300T, 450T, 600T, 800T, 100T, 1500T injection machines. |

| Inspection | 100% inspection by QC, QA before shipping. |

| Applications | Electronics industry, Medical industry, Home appliance industry, Aerospace, Shipbuild industry, Household appliance, Automobile industry, Machinery industry,Machinery industry,Semicoductor industry,Food processing, Robot industry,etc. |

| Quality Certification | ISO9001 quality management system certification. |

| ISO14001 environment management system certification. | |

| Package | Plastic bags, air bubble bag, EPE foam, master cartoon, wooden case, pallet. |

Custom made all kinds Plastic Enclosure, and also with surfacefinishing:Painting,Printing,Water trans-print,Welding,Assembly etc.

1.) We provide plastic injection molding services to various range of industries.

2.) Our expertise & facilities can meet customers’ low volume to high volume order request.

3.) We offer two shot color and insert injection molding.

4.) 10K&100K clean room for the medical, foodgrade and high precision electronics parts.

5.) 80T to 1500T Injection machine for micro parts, thin-walled parts, and large components.

6.) Do very closely color match for your productions according to PANTONE and RAL.

7.) Offer secondary hand services. including ultrasonic welding, gluing, pad printing, plating, and packaging.

8.) Automatic robots are used in manufacturing processes, help high quality and cost saving.

Once mould is completed

1.) Run mould trial T0 samples for enginner self-checking.

2.) Then we will modify the mould improve the appearance and correct each dimensions in T1 samples, and delivery to customer approval.

3.) Then prepare the raw material and IQC inspection. Then mixture color mastbantch, and adjustment parameter for molding.

4.) During the mass production, there are many times of routing inspection.

5.) After complete produce, we will arrange the 100% quality inspection, assembly and packing.

Finally send the packing list to customer for the shipment.

More than 100+ kinds of plastic materials for selection, meet your products different requirements perfectly!Engineer can give correct suggestions for your products.

Each plastic material from well-know brand , ensure injection molding productions quality perfectly!

We purchase steel from well-know brand, ensure mould durable quality.

| Popular Mould Steel Selection Table | ||||||

| SWEDEN | USA | JAPAN | GERMANY | Steel Properties | Hardness Supplied | General Application |

| ASSAB | AISI | JIS | DIN | |||

| 760 | 1050 | S50C | CK53 | High- strength carbon steel. | Annealed HB 200 | Not good in welding properties and hardenability, but no temper brittleness, cutting performance is acceptable. More used as a mold base or cavity insert with lower requirement. |

| 618 | P20 | PDS3 | 1.2311 | Pre-hardened, general-purpose plastic mold steel. | Prehardened to HB 290-330/ HRC 27-32 | Good etching and polishing for mold texture, pre-hardened steel. It could use as cavity insert without quenching. |

| 718 | P20 | PDS5 | 1.2738 | Pure and uniform,containingabout 1% of nickel. | Prehardened to HB 290-310/HRC 27-32 | High quality mold inserts, suitable for non-Flame Retardant plastic tooling of PA, POM,PS,PE, PP, ABS. |

| 718H | P20 | PDS5 | 1.2738 | Prehardened to HB 330-380/HRC 33-38 | ||

| NAK80 | P21 | NAK80 | GH1180 | Prehardened Pure and uniform. | Prehardened to HB 352-401/HRC 38-42 | Pre-hardened condition PVC, PA, POM, PC, PMMA. |

| S136 | 420 | SUS420J2 | 1.2083 | High purity, high degree of mirror polishing onoptical application, excellent ability of anti-rust and anti-acid. | Heat treating HRC 48-52 | High quality mold inserts with mirror surface finish and goodcorrosion resistance, anti-corrosive cooling channel, suitable for plastic tooling of Pre-hardened condition PVC, PA, POM, PC, PMMA. |

| S136H | 420H | SUS420J2 | 1.2316 | Prehardened to HB 290-330/ HRC 27-32 | ||

| 8407 | H13 | SKD61 | 1.2344 | Hot work steel, high toughness and good heat resistance. | Heat treating HRC 48-52 | Suitable for long lasting required cavity insert, metal casting, extrusion die and plastic mold of PA, POM, PS, PE and engineering plastic. |

Since 2003, SANDO is a professional OEM & ODM plastic injection mould and injection molding manufacturer with 20+ years experiences in Dongguan city. there are 200 employees, factory occupied area is over 8000 square meters. Major markets are for Consumer Electronics, Household Appliances, Medical Parts, Automobiles, Aviation and Artificial Intelligence Industries. our team have the capability of product research and development (R&D), we can help our customers projects from ideas come to true. the company has audited by ISO9001 quality and ISO14001 environment management system certification. Our engineering team members have ever worked projects for FOXCONN, TESLA, JABIL,and CANON well-know firms for many years experience. our leader and sales can be highly efficient & fluent communication with customer in technical term English very well with fast respond way.

Our capacity are 300 sets moulds for each year. we have OKUMA CNC, CHARMILES EDM machine, SODICK wire-cut machines etc. the maximum CNC machining capability is 1.5 * 1.0 meter, the tolerance can be +/- 0.002mm. with these high accurate Equipments, ensure your mould and productions high precision quality. We have confidence & capability challenging and solution difficult plastic products problem for your projects. we strictly practice Non-disclosure agreement with each customer. 100% ensure good quality, on-time delivery, SANDO team members treat every customer attentively and considerately. No matter big or small projects, customer satisfaction is always our persistent pursuit. we appreciate and cherish every your business chance! With our accurate machining, competitive cost and good impressive customer service, let's start from an inquiry. looking forward to cooperation with you!

Our Quality Control Procedure:

1.) Incoming quality control ( IQC): Checking the raw material once they reach our factory.

2.) In process quality control(IPQC): Have full inspection and routing inspection checking the appearance, key dimensions, warpage and other requirements according to drawings specification during mass production.

3.) Final quality control(FQC): Do 100% inspection the goods after they are finished.

4.) Outgoing quality control(OQC): Checking the goods before shipping.

We control quality strictly according to ISO 9001 system & ROHS, try our best to make high quality and reasonable price productions for customers.

1. Does your company make mould by yourself?

A: Yes, we are manufacturer with about two decades of molding experience.

2. How many kinds of moulds can you make? Only make the moulds?

A: We can make many kinds of moulds, such as plastic injection moulds, blowing moulds,stamping mould,die casting moulds and silicone rubber moulds. Besides, we also can produce the final parts for you.

3. What's the software you will use to check the drawing? And what's format of drawing you can check?

A: Our designers and engineers all use AUTO CAD and Soliworks software to check 2D and3D drawings. We can check the drawings with PDF, Al, DWG(CAD)and STP (3D)or IGS(3D)formats.

4. Will you send me the free sample?

A: Yes, but you should charge the freight by yourself. We can return the fee if you place a bulk.

5. How to pack the moulds and products?

A: For moulds, we will be coated one-layer anti-rust oil first, and then also will be covered thin films on the mould, finally pack into non-fumigation wooden case. And as to products, we will pack into standard export cartons or as per customers request to pack.

Похожие товары

Лидер продаж Чжэцзян, изготовленные на заказ детали для литья под давлением из АБС-пластика, полипропилена

OEM PA PP TPU PVC ABS TPR пластмассовое литье под давлением, быстрый прототип, индивидуальные детали, сервисная форма, резиновая пластиковая литьевая форма

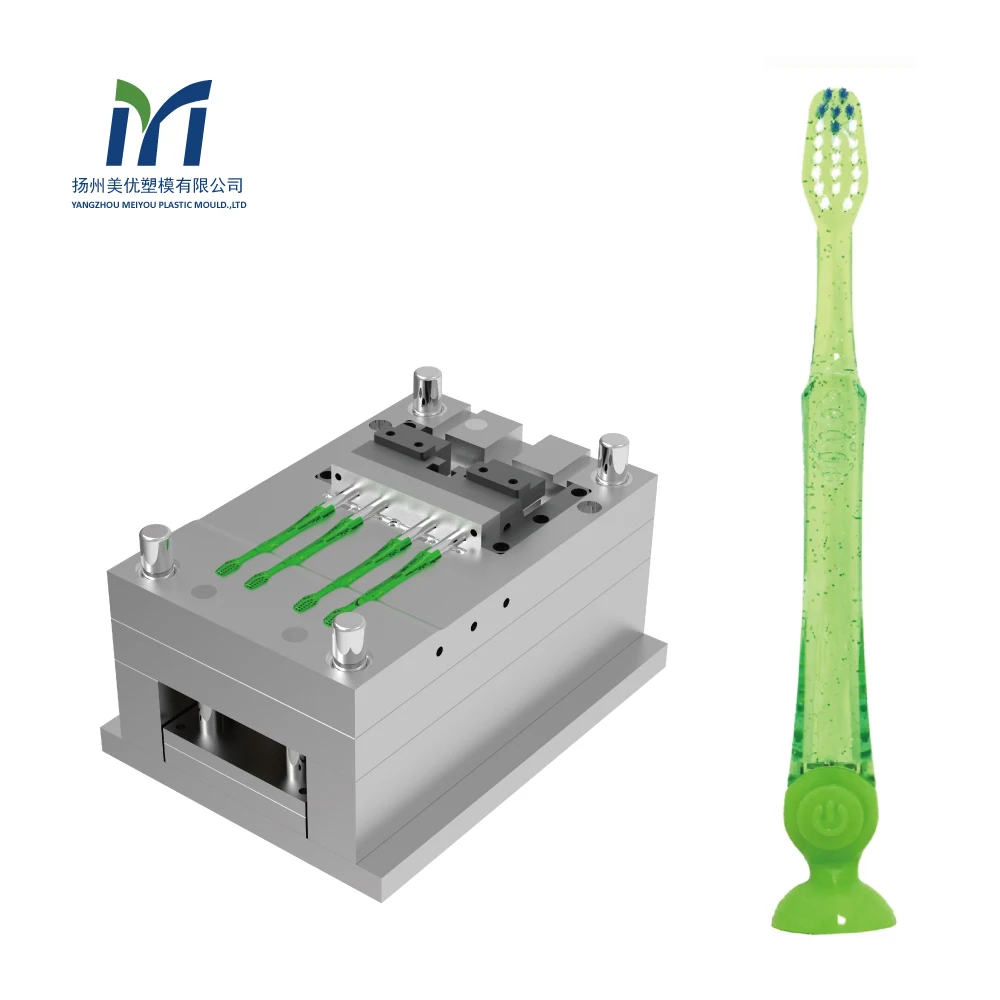

Детский пресс-формы для зубной щетки

Пресс-форма для литья под давлением

Taizhou, Китай, пластиковые литьевые формы для литья под давлением, для детей, туалета, ресторанный обеденный стол, пресс-формы, завод

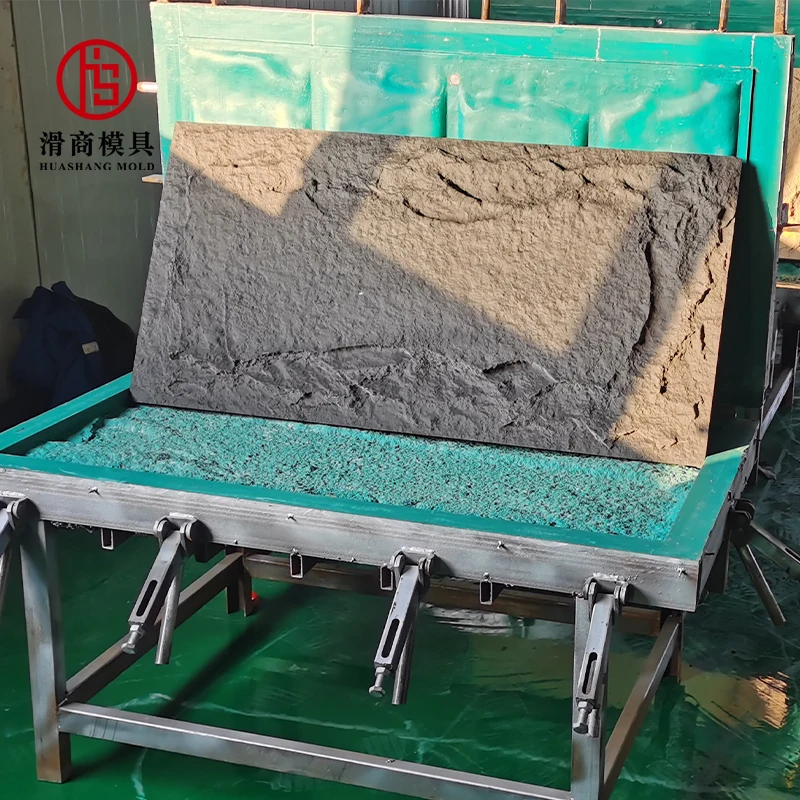

Облицовка искусственный камень гриб PU искусственный камень доски для изготовления PU стеновых панелей плесень

Легкая Искусственная каменная панель настенная искусственная культура каменная настенная панель машина

Новые поступления

Новинки товаров от производителей по оптовым ценам