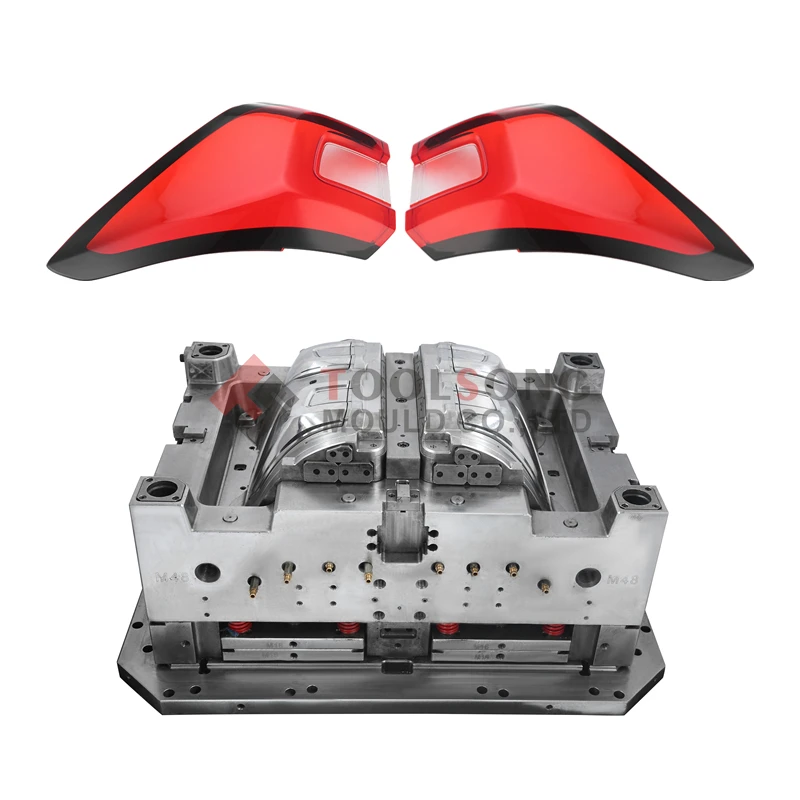

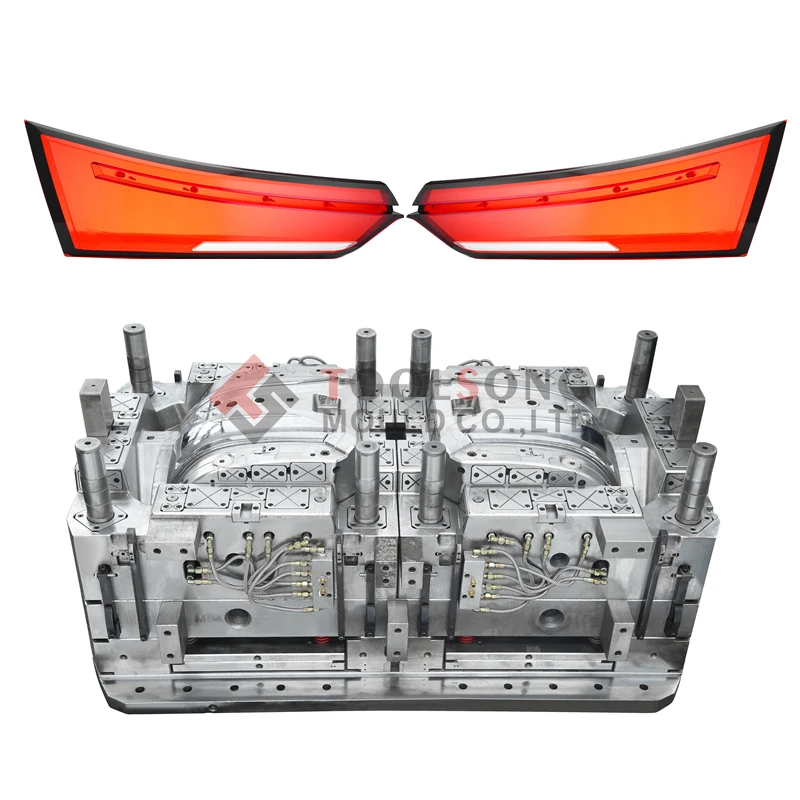

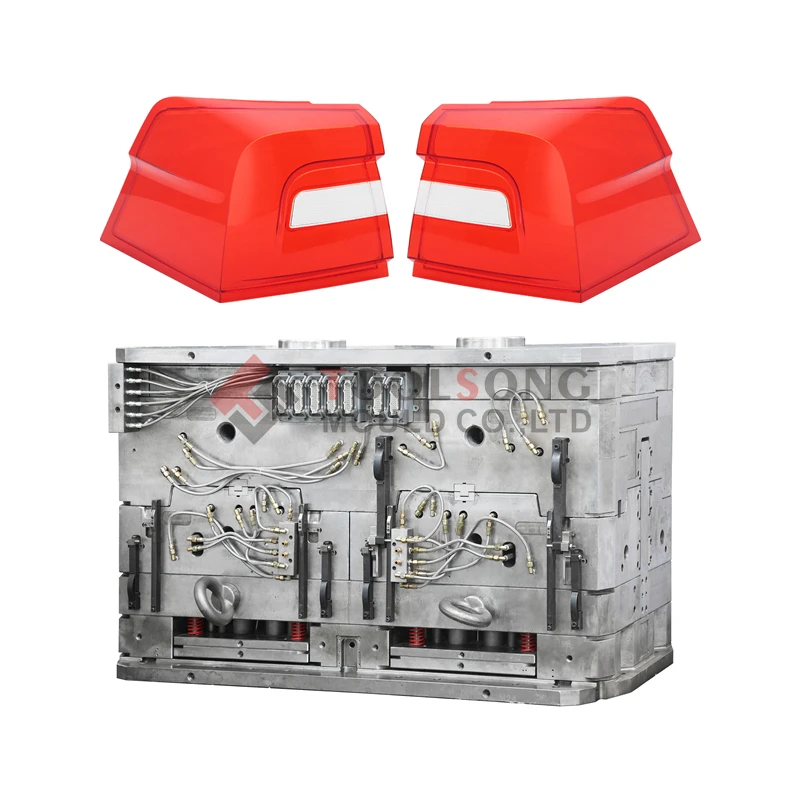

Пластиковая литьевая форма для задних фар

- Категория: >>>

- Поставщик: Taizhou Toolsong Mould Co. Ltd.

Сохранить в закладки 1601263699559:

Описание и отзывы

Характеристики

Product Name | Plastic Injection Mold Rear Light Lens Mould Car Exterior Accessories Automotive Lighting 2K Taillight Lens Cover Mould |

Mold Life | 300,000-1,000,000 shots |

Plastic Material | PC, PMMA |

Mold Steel | NAK80, 1.2343ESR, 718HH, SMV3W, etc |

Injection System | HRS, Moldmaster, Synventive hot runner |

Ejection System | Pin ejection, blade ejection, hydraulic ejection, air ejection, etc |

Used | Automotive part manufacturing industry |

We are committed to providing every customer with high quality mold by below steps.

1) Raw material inspection;

2) Part visual inspection & dimension inspection;

3) Mold inspection before T1 trial;

4) Mold CMM inspection;

5) Mold disassembly to inspect cooling system, injection system, ejection system before shipment, etc.

Film wrapping

Wooden case package

Delivery

Q: How long is your delivery time?

A: Generally 40-60 days.

Q: When can I receive the quotation?

A: Usually within 24-48 hours (except festival holidays).

Q: Is it possible to know manufacturing status without visiting your company?

A: We will provide the schedule of mold making, send weekly reports with digital pictures or videos which show every manufacturing progress.

Q: What is your terms of payment ?

A: Payment Terms: 40% along with invoice, 30% after T1 sample submit, balance before shipment.

Похожие товары

Нестандартные аксессуары для оборудования, прецизионные формовочные детали, литьевые формы, штампованные штамповочные компоненты, детали для пресс-форм на заказ

Прогрессивный металлические штамповочные прессы пресс-форм удар пуля голова стальное зубило для пресс-форма

Подгонянный металлический перфоратор

Запчасти для пресс-форм SKD11SKH51

Перфоратор для пирсинга HSS HWS

Высокоточная обработанная стальная Фланцевая Втулка с ЧПУ, стальная втулка, металлический редуцирующий втулка

Устойчивость к коррозии, ржавчина, выталкивающий штифт из нержавеющей стали, втулка, покрытие, термообработка, игольчатый перфоратор

Новые поступления

Новинки товаров от производителей по оптовым ценам