Изготовленные на заказ детали для штамповки листового металла Высококачественная алюминиевая нержавеющая Лазерная режущая часть

- Категория: >>>

- Поставщик: Sichuan Kunshuo Import And Export Trading Co. Ltd.

Сохранить в закладки 1601265299851:

Описание и отзывы

Характеристики

Product Name

Custom High Quality Aluminum Stainless Steel Sheet Metal Stamping Parts Laser Cutting Part

Product Overview

Metal Stamping

In metal stamping flat metal sheets are fed in the stamping press which is then transformed into different desired shapes. Stamping process is also called pressing. This process includes a number of techniques like punching, blanking, piercing, coining, embossing and so on.

The design for metal stamping has to be precise so that each punch on the metal sheet will result in optimal part quality. Die stamping components can have curved bends and all the bends can be done at once. Progressive die stamping is one of the major techniques used in metal stamping die.

The design for metal stamping has to be precise so that each punch on the metal sheet will result in optimal part quality. Die stamping components can have curved bends and all the bends can be done at once. Progressive die stamping is one of the major techniques used in metal stamping die.

PRODUCT SPECIFICATIONS

Material | Carbon steel, SPCC, SGCC, Stainless steel, Aluminum, brass, Copper, etc. | |||

Surface treatment | Zinc/Nickel/Tin plating, Sand blasting, Powder coating, Painting, Passivation | |||

Process | Tooling making, Prototype, Cutting, Stamping, Welding, Tapping, Bending and Forming, Machining, Surface treatment, Assembly | |||

Size | Customized,According to customer’s drawings or samples | |||

Certificate | ISO9001:2015/IATF 16949/SGS/RoHS | |||

MOQ | As per client’s products | |||

Software | Auto CAD, 3D(STP, IGS, DFX), PDF | |||

Application | Automotives, Home appliances, Furniture accessories, Electronic components,New Energy Products etc. | |||

Tolerance | ±0.003mm | |||

Service | OEM/ODM |

FEATURES AT A GLANCE

PRODUCT CONFIGURATION

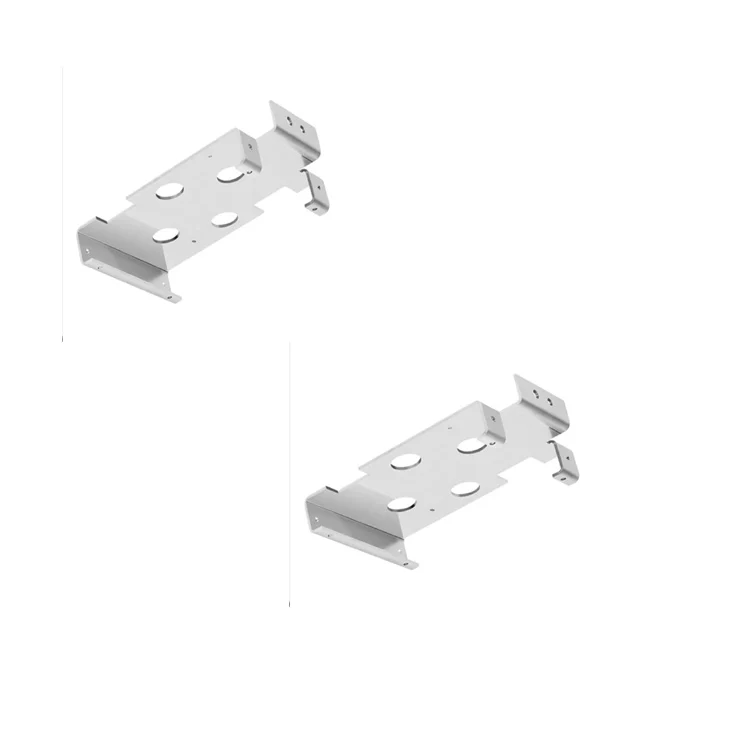

Sheet Metal Stamping Products

Sheet Metal Stamping Products

Sheet Metal Stamping Products

Sheet Metal Stamping Spring Products

Sheet Metal Stamping Spring Products

Sheet Metal Stamping Spring Products

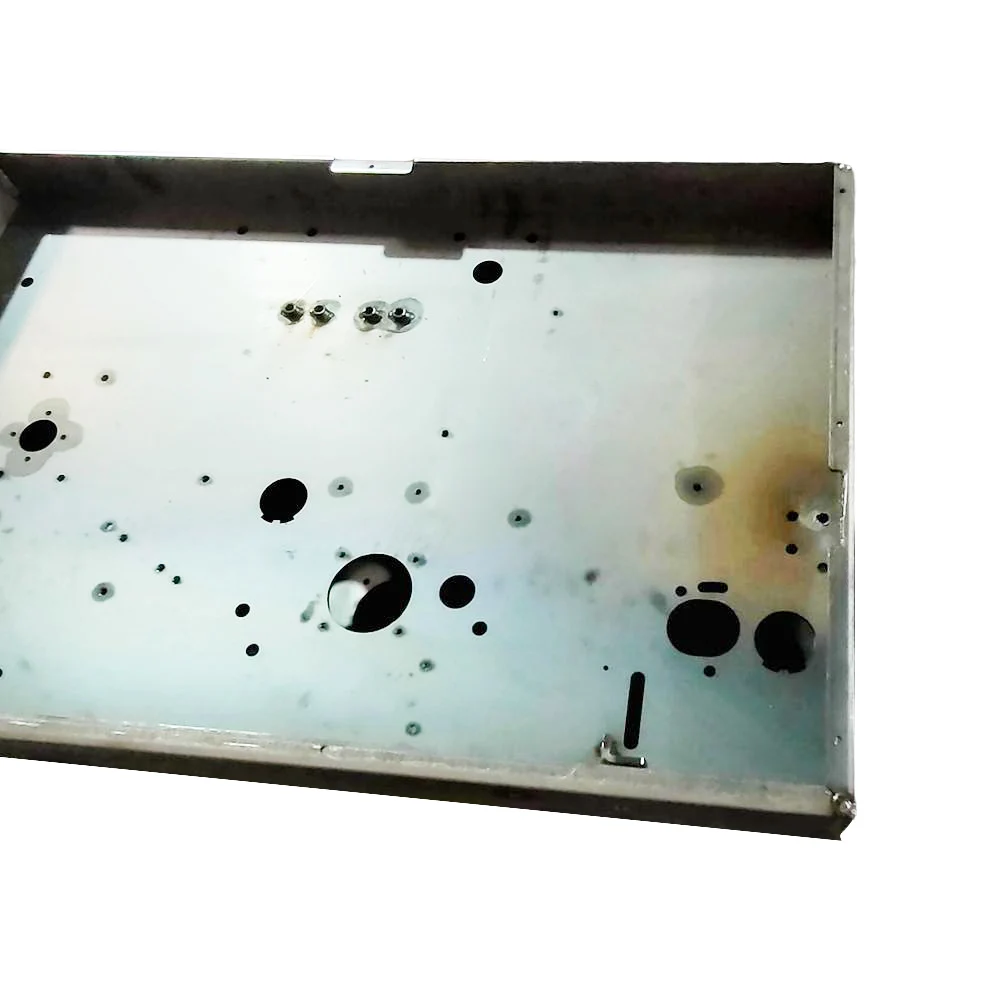

Sheet Metal Fabrication Enclosure Product

Sheet Metal Fabrication Enclosure Product

Sheet Metal Fabrication Enclosure Product

SALES AND SERVICE NETWORK

Company Profile

Ks Tech, founded in Dongguan, GuangDong,China, is a reputable company specializing in the manufacturing of metal hardware parts and plastic parts. We have established ourselves as a leader in the industry by leveraging their advanced machinery and equipment, including CNC milling machines, CNC turning lathe machines, metal stamping machines, laser cutting sheet metal fabrication machines, CNC spring machines, plastics injection machines, and fasteners machines.achine

Factory Photos

One of the key strengths of Ks Tech lies in our commitment to quality assurance.We have implemented a robust quality control system that ensures the highest standards in their manufacturing processes. We have a highly skilled team of engineers who possess extensive knowledge and expertise in their respective fields.

With our focus on quality assurance, engineering advantages, and continuous improvement, Ks Tech is dedicated to delivering excellent manufacturing services, meeting specific design requirements, and building strong relationships with customers worldwide. Our commitment to customer satisfaction has earned us a solid reputation and a diverse customer base across various industries.

With our focus on quality assurance, engineering advantages, and continuous improvement, Ks Tech is dedicated to delivering excellent manufacturing services, meeting specific design requirements, and building strong relationships with customers worldwide. Our commitment to customer satisfaction has earned us a solid reputation and a diverse customer base across various industries.

Main Available Manufacturing Raw Material

Engineering A professional engineering team is the key for a metal and plastic harware parts company`s success.

Focus On Details We focus on details for each of project from our customers

The Skill Of Workers Ks Tech has been committed to training workers in machining programming and production skills

Trust Customer trust is our driving force for success

Successful Project

American customers came to inspect the factory

French customers came to our company for inspection

Pakistani customers came to our factory for inspection

FAQ

Q: What do you need to provide a quote?

A: It will be worked for us if you have the drawing of the product, we would send you our best offer based on your drawing.

But it is ok for us if you don't have the drawing, we accept the sample, and our experienced engineer could quote based on your samples.

Q: What is your terms of payment ?

A: 30% paid to start the mass production and 70% balance paid at the sight of copy of B/L.

Q: What is your production leading time?

A: Normally 7-10 days, depends on order quantities.

Q: What will you do for after-service?

A: When our metal parts apply to your products, we will follow-up and await for your feedback.

If need any help of the assembly or other matters, our professional engineer will give you a best solutions.

Q: What delivry can I choose?

A: FOB/CIF/EXW/Express delivery are all avaliable.

Q: How can I get samples?

A: We could offer 10pcs free samples for you to check quality.

Q: What is the MOQ?

A: Usually we don't set MOQ, but the more, the cheaper. Besides, we are happy to make prototype or sample for clients to ensure quality standa.

A: It will be worked for us if you have the drawing of the product, we would send you our best offer based on your drawing.

But it is ok for us if you don't have the drawing, we accept the sample, and our experienced engineer could quote based on your samples.

Q: What is your terms of payment ?

A: 30% paid to start the mass production and 70% balance paid at the sight of copy of B/L.

Q: What is your production leading time?

A: Normally 7-10 days, depends on order quantities.

Q: What will you do for after-service?

A: When our metal parts apply to your products, we will follow-up and await for your feedback.

If need any help of the assembly or other matters, our professional engineer will give you a best solutions.

Q: What delivry can I choose?

A: FOB/CIF/EXW/Express delivery are all avaliable.

Q: How can I get samples?

A: We could offer 10pcs free samples for you to check quality.

Q: What is the MOQ?

A: Usually we don't set MOQ, but the more, the cheaper. Besides, we are happy to make prototype or sample for clients to ensure quality standa.

Professional hardware processing, presenting excellent quality, leading the industry trend

Похожие товары

Высокое качество индивидуальные услуги по изготовлению листового металла алюминиевые и медные фитинги

548,25 ₽ - 1 644,73 ₽

Изготовление на заказ листового металла алюминиевая нержавеющая сталь лазерная резка Гибочные штамповочные детали из медной латуни и цинка

43,86 ₽ - 54,83 ₽

Лазерная резка деталей из нержавеющей стали алюминиевый листовой металл производственный завод

Высокое качество на заказ с ЧПУ механическое оборудование для обработки деталей штамповки металлических из листового металла

164,48 ₽ - 1 085,52 ₽

Стальной металлический штамповочный комплект гибочных штамповочных деталей из листового металла по индивидуальному заказу завода OEM принимает 1 образец. Бози

54,83 ₽ - 109,65 ₽

Изготовление металла из нержавеющей стали по индивидуальному заказу прочные коррозионные листы штамповки соединительные трубы зажимы детали

21,93 ₽

Высокоточные металлические штамповочные зажимы для полировки ковша на заказ из нержавеющей стали

16,45 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $