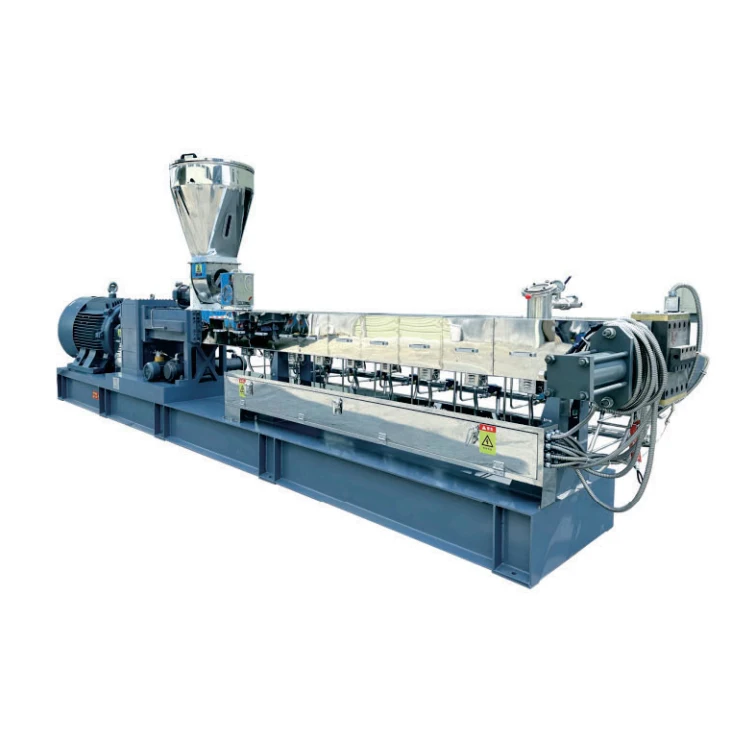

Встроенный двухвинтовой пластиковый гранулятор для производства пластиковых гранул

- Категория: >>>

- Поставщик: Ningbo Chaoyifan Plastic Machinery Co. Ltd.

Сохранить в закладки 1601266979794:

Описание и отзывы

Характеристики

The twin-screw granulator is suitable for making new material color matching, new material or regenerated particle modification (adding glass fiber, calcium carbonate, color masterbatch, etc.) and other products. It has the characteristics of good mixing, good plasticization, high output, high density of plastic particles, bright surface gloss, and no hollow particles. Therefore, the re granulation industry is widely used.

1. Adjust different thread combinations according to different raw materials, different forms of raw materials (raw material size), different formulas (whether glass fiber is added, whether additives are added, the content of additives, and the form of additives), so as to achieve the purpose of one machine with multiple uses and special raw materials.

2. The twin-screw is made of W6MO5Cr4V2 threaded element, and the cylinder is made of C-type alloy bushing, which has better wear resistance and long service life. The heater is 5.2kw cast iron heater, which has high power and fast heating; Each cylinder is equipped with a cooling water circuit, and the water volume is controlled automatically by a solenoid valve to ensure a more stable heating temperature.

3. The machine shall be equipped with an iron removal conveyor belt to remove metal impurities in the plastic and reduce the damage of metal to the screw.

4. The host adopts quantitative feeding, and is equipped with frequency conversion speed regulation. The feeding amount of the feeding screw is controlled by the rotation speed of the feeding screw. In addition, the installation of the feeder can reduce the wear of the screw and improve the service life of the screw.

• For the loose cargo we will packing by wooden box.

• For the full container loading we are packing the machine by film and some on pallet accordingly.

• We can also ship the goods by air or by sea as buyer request.

• We will send pictures of cargo loading to our client to check and keep recording.

• We can send cargo to client's warehouse to loading.

• In-sales: we supply the details layout, installation instruction, and technician support for the clients.

• After sales: We have subsidiaries overseas to provide sales and after-sales services, including Taiwan, Japan, Thailand, Malaysia, Philippines, Indonesia. we arrange engineer to install the machine and train the workers for our client.

• We have 24 hours online service to solve the after sales problem.

• We have free spare parts with the machine.

• We supply long term spare parts for every customer.

• We supply lifetime after sales service.

• We always update the new technology to every customer.

In order to match your requirement and provide you a proper quotation, please advise:

• What material do you want to recycling? ABS? PP? PE? PC? PBT? or other material?

• What capacity(kg/h) do you want?

• What is the final size(mm) of flakes you want?

• Other special requirements about the polyester fiber pelletizing machine you needt.

Q1:Do you support overseas after-sales service?

A: Yes, We have subsidiaries overseas to provide sales and after-sales services, including Taiwan, Japan, Thailand, Malaysia, Philippines, Indonesia.

Q2:how long is the warranty?

A:Within 1 year from date of the factory, if parts failure or damage

(because of the quality problem ,except wearing parts)

Q3:Do you provide technical support?

A:We provide lifelong technical support and offer on-site installation services overseas. Help each customer solve problems is our original intention.

Q4:The factors of plastic granulator line price?

1. Voltage and frequency in your country

2. The raw materials you are going to deal with, ABS PP PE PVC PET?

3. The output per day

4. The cleanliness of the raw materials, whether it needs to be cleaned (it is best to provide raw material pictures)

Q5:What is your payment term ?

A: 30% T/T in advance ,70% balance before shipment or Negotiable

If you have another question, please feel free to contact us.

Похожие товары

Биоразлагаемый экструдер для пластиковых частиц PP/PE линия для гранулирования

Пластиковый гранулятор

Китай Высокое качество пластиковая нить/резьба гранулятор

Большая химическая машина для производства пластиковых частиц пластиковые грануляторы

Машина для производства пластиковых грануляторов

Новая древесно-пластиковая грануляторная машина для переработки отходов

PERT EVOH машина для производства труб горячей

Новые поступления

Новинки товаров от производителей по оптовым ценам