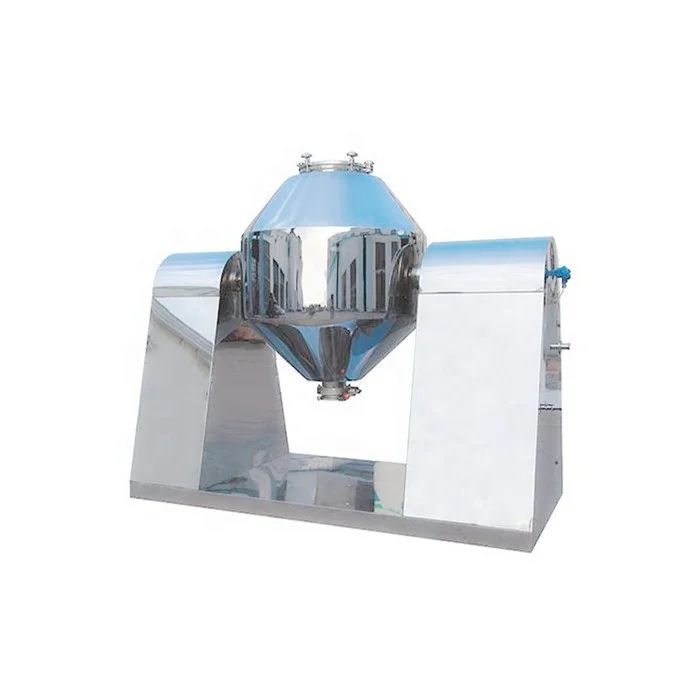

Китай новый двойной конус Вакуумная сушилка литий железо фосфат вакуумного барабана сушильное оборудование цена

- Категория: >>>

- Поставщик: Liaoyang Wintech Industrial Co. Ltd.

Сохранить в закладки 1601267173877:

Описание и отзывы

Характеристики

Product Overview

China made new condition SZG low price double cone vacuum dryer for bio-plastic particle

The double cone rotary vacuum dryer is a new type of vacuum dryer integrating mixing and drying. Under the vacuum state in the tank, steam or hot water is introduced into the jacket for heating. The heat is in contact with the wet material through the inner wall of the tank. The water vapor evaporated after the wet material absorbs heat is pumped away through the vacuum exhaust pipe through the vacuum pump. Because the tank body is in a vacuum state, and the rotation of the tank body makes the materials constantly turn up, down, inside and outside, it speeds up the drying speed of the materials, improves the drying efficiency and achieves the purpose of uniform drying. The double cone rotary vacuum dryer system is mainly composed of double cone rotary vacuum dryer, condenser, dust collector, vacuum pumping system, heating system, cooling system, electric control system, etc

MIXING&DRYING

EASY OPERATION

SAFETY STRUCTURE

SIMPLE CONTROL

EASY MAINTENANCE

VERSATILITY

VARIOUS MODELS

LOW TEMPERATURE DRYING

1.When oil is used to heat, use automatic constant temperature control. It can be used for drying biology products and mine. Its temperature of operation can be adjusted form 20-160 ℃ .

2.Compared to ordinal dryer, its heat efficiency will be 2 times higher.

3.The heat is indirect. So the raw material can not be polluted.

4.It is in conformity with the requirement of GMP. It is easy in washing and maintenance.

Principle

Let heat source (for example, low pressure steam or thermal oil) pass through the sealed jacket. The heat will be transmitted to raw material to be dried through inner shell;

Under driving of power, the tank is rotated slowly and the raw material inside it is mixed continuously. The purpose of reinforced drying can be realized;

The raw material is under vacuum. The drop of steam pressure makes the moisture (solvent) at the surface of raw material become saturation and will evaporate. The solvent will be discharged through vacuum pump and recovered in time. The inner moisture(solvent) of raw material will infiltrate, evaporate and discharge continuously. The three processes are carried out unceasingly and the purpose of drying can be realized within a short time.

Product Parameters

Below is the technical parameter of the dryer, if you need, we can also help to select the model for you! |

Application Field

This machine is suitable for vacuum drying and mixing of powder and granular materials in food, chemical and other industries, especially for materials with the following requirements:

1. High temperature heat sensitive materials cannot be accepted;

2. Easily oxidized and dangerous materials;

3. Materials requiring recovery of solvents and toxic gases;

4. Materials with extremely low residual volatile content are required;

5. It is required to mix the materials fully and evenly.

2. Easily oxidized and dangerous materials;

3. Materials requiring recovery of solvents and toxic gases;

4. Materials with extremely low residual volatile content are required;

5. It is required to mix the materials fully and evenly.

Product More Pictures

Packing and Shipping

The machine is wrapped with protective film

Safety delivery

Company Profile

LIAOYANG WINTECH INDUSTRIAL CO.,LTD, takes Centrifuge Equipment and Drying Equipment processing and manufacturing as the main industry, main products are Horizontal Decanter Centrifuge, Disc Centrifuge, Tubular Centrifuge, Flat Series Centrifuge, CO2 Supercritical Extraction Equipment, Spray Dryer, Fluid Bed Dryer, Drying Oven, Drum Dryer and corresponding supporting equipment. At the same time, to undertake standards and non-standard products. Our equipment is exported to Europe, America, Southeast Asia, Africa and other countries, and has been praised by foreign customers.

Our company has professional engineers with strong new product development ability, and can develop equipment products according to the actual needs of customers. Our company has ISO 9001 certification, CE certification and other relevant authoritative parts of professional identification and recognition. At the same time, facing the fierce market competition, our company is relying on its own advantages, integrating external resources, optimizing internal management, constantly exploring and innovating, and striding forward in the direction of business specialization and diversification. Our company adheres to the business philosophy of quality and service, and wholeheartedly provides high-quality products and services for new and old customers to meet the needs of customers to the maximum extent. Serve customers, achieve customers, sincerely look forward to cooperating with new and old customers to create a better future.

Our company follows strict quality controls and various systematic procedures. We take utmost care of quality at every stage of the manufacturing process.Our research and development wing is our asset that develops and incorporates innovative ideas and products. Our Team is full of experienced and qualified professionals, who have sound knowledge about the quality of our machinery.

We sincerely invite you to be our long term relationship friend , and we always prepared to provide our best services for you and would like you to know below we want to present :

1. Each machine is manufactured by professional experienced staff.

2. 12 months warranty + 100% QC inspection Before Shipment.

3. Overseas services provided. Technicians can be sent to spot for guiding the installation and debugging. Training operators and accomplish the commissioning.

4. Consultant services for whole machine life, 24 hours technical support by email and phone.When warranty date expired, lifetime maintenance service is provided and at buyer’s cost.

SIMILAR PRODUCTS

FAQ

1. What data is required to confirm the model?

(1) Materials to be dried (2) Treatment capacity per hour (3) Moisture requirements before and after drying (4)Heating source(electricity/ gas/ thermal oil, etc)

2. What certificates do you have?

We can provide CE, ISO 9001, etc.

3. What is the warranty period of the equipment?

Normally 1 year warranty.

4. Can we visit your factory?

Sure, we sincerely invite you to visit, if it's not convenient for you, you can visit our factory and solve problems through video conference.

5. Can we bring our own materials to your factory for experiments?

Sure, you are welcome at any time. We will arrange professional engineers and technicians to do experiments and analyze data for you on site.

6. Can it be customized?

No problem, our equipment can be customized according to the actual requirements of customers.

7. How long is the construction period?

It's about 30 days, but it also needs to be determined according to the specific equipment model, order number, etc., But if you need it urgently, please let us know, we can arrange the factory to rush production.

8. Will you provide installation services?

If you need, we can arrange professional technicians and engineers to install and debug on site.

(1) Materials to be dried (2) Treatment capacity per hour (3) Moisture requirements before and after drying (4)Heating source(electricity/ gas/ thermal oil, etc)

2. What certificates do you have?

We can provide CE, ISO 9001, etc.

3. What is the warranty period of the equipment?

Normally 1 year warranty.

4. Can we visit your factory?

Sure, we sincerely invite you to visit, if it's not convenient for you, you can visit our factory and solve problems through video conference.

5. Can we bring our own materials to your factory for experiments?

Sure, you are welcome at any time. We will arrange professional engineers and technicians to do experiments and analyze data for you on site.

6. Can it be customized?

No problem, our equipment can be customized according to the actual requirements of customers.

7. How long is the construction period?

It's about 30 days, but it also needs to be determined according to the specific equipment model, order number, etc., But if you need it urgently, please let us know, we can arrange the factory to rush production.

8. Will you provide installation services?

If you need, we can arrange professional technicians and engineers to install and debug on site.

Похожие товары

50 100 200, 300 кг в час, цена, пищевая Органическая черника, моментальная вакуумная сублимационная сушка, производственная машина

6 578 904,00 ₽

Серия ZKG, новая сушилка для производства пищевых отходов, вакуумная сушильная машина для борон

Вакуумная сублимационная сушилка для морепродуктов вакуумная сублимационная машина вакуумная сублимационная сушка машина

274 121,00 ₽

Машина для сушки горячим воздухом серии ZKG Вакуумная сушилка для борона для производства моющего средства для кальцинированной соды

Оборудование для сушки одежды

1 644 726,00 ₽ - 1 864 022,80 ₽

Промышленная вакуумная сублимационная сушилка машина для сублимационной сушки для пищевых продуктов

3 774 536,53 ₽

Портативный лиофилизатор сублимационная сушилка небольшая емкость электрическое нагревательное оборудование для сублимационной сушки

197 367,12 ₽ - 208 331,96 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Рекламный надувной самолет украшение для костюма самолета ходячие костюмы продажи

C100 % восковая ткань с принтом китайские поставщики поставляют настраиваемые печатные африканские восковые ткани

0,93-0,97 $

Прямые продажи с фабрики могут быть оптовые складные тележки для покупок Удобные и уличные продуктовые

8,39-9,89 $

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $