Квадратная круглая лента для лазерной резки

- Категория: >>>

- Поставщик: Shenzhen Hochuen Technologies Co. Ltd.

Сохранить в закладки 1601267384399:

Описание и отзывы

Характеристики

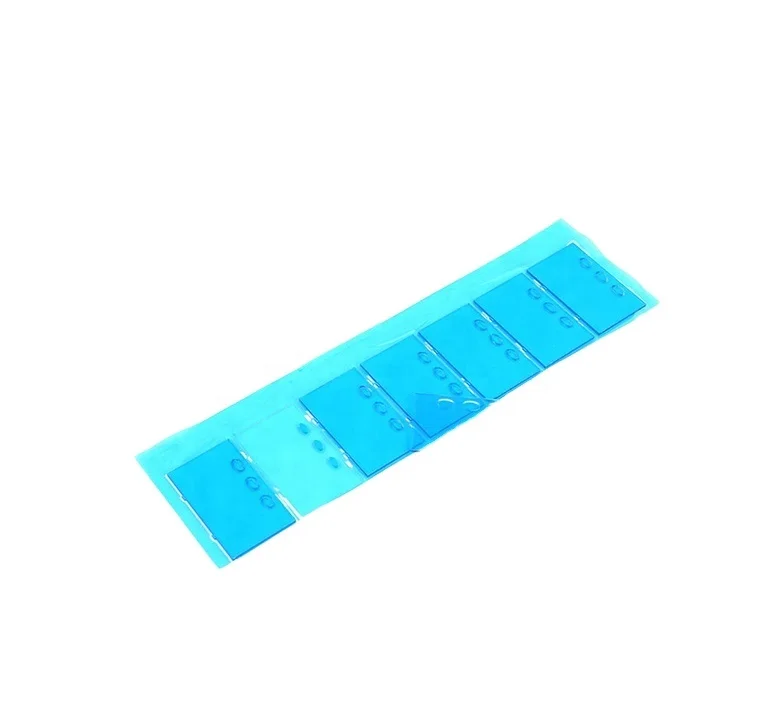

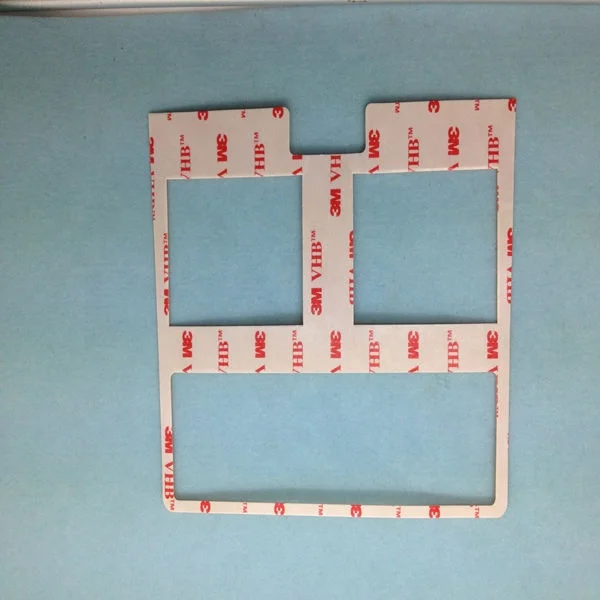

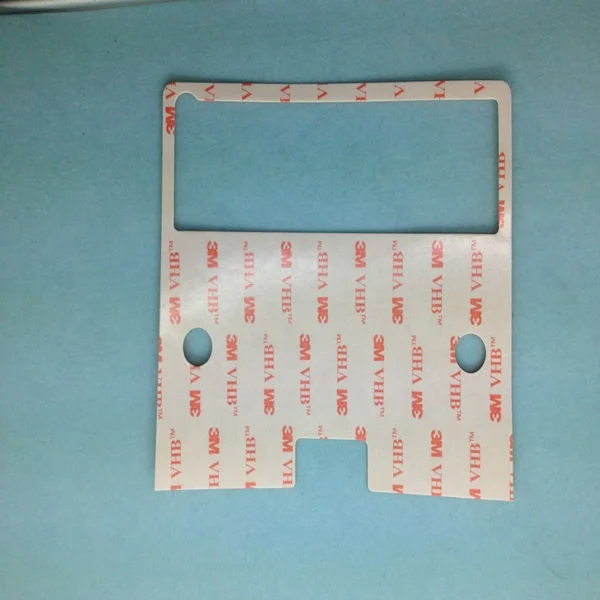

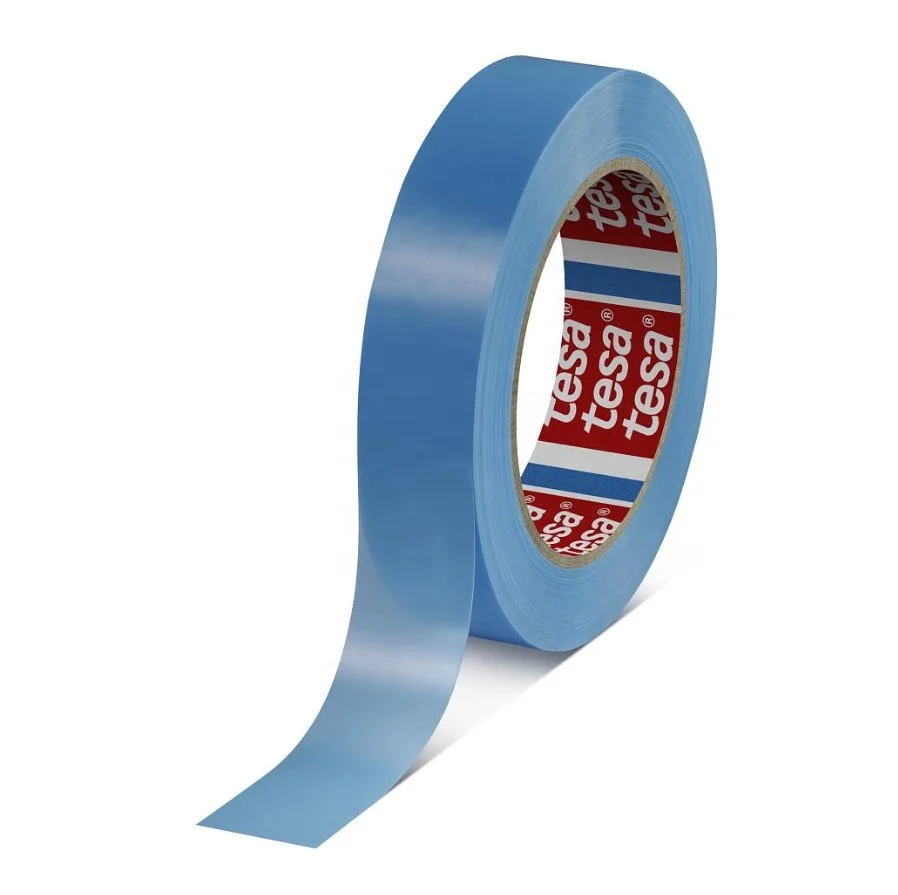

Pre Cut Square Round Circles Strips Laser Cutting Custom Foam Mounting Tape Sheet Pad Die Cut Adhesive Tape for Medical Device

Product Name | Die Cutting Tapes/Gaskets |

| Material | Films, foams or tapes according to different applications |

| Drawing Format | 2D design like PDF, AI, DWG, etc. |

| Shape | Round, square or customized |

| Size | Customized |

| Certification | ISO9001, ISO14001, ISO13485 |

| Die Cut Method | Flat die cutting, rotary die cutting, laser cut, multi-layer lamination, etc. |

| Application | Medical, electronics, healthcare, automotive,industrial, etc. |

| Tolerance | Normally ±0.05mm |

| Workshop | ISO13485 cleanroom die cutting & assembling |

Why choose Hochuen as a manufacturing partner?

Experience: With two decades of experience, Hochuen factory have a deep understanding of the unique requirements and regulations of the industries. Hochuen have encountered a wide range of challenges and developed effective solutions over the years.

Expertise: As a long-established factory, Hochuen have honed our die cutting techniques and processes specifically for medical devices, ensuring precision, consistency, and quality in our products.

Quality Control: Over time, Hochuen factory have refined their quality control processes to meet the stringent standards required for medical devices. They are likely to have robust quality assurance protocols in place to ensure the products meet regulatory requirements.

Regulatory Compliance: With two decades of experience in manufacturing medical devices, Hochen have a thorough understanding of regulatory standards such as ISO 13485 and F.D.A regulations. We are well-equipped to navigate the complex regulatory landscape and ensure compliance in their manufacturing processes.

Innovation: A factory that has been in operation for 20 years is likely to have invested in innovation and technology advancements to stay competitive and meet the evolving needs of the medical device industry or other fields. We have access to advanced die cutting equipment(like flat die cutting or rotary die cutting machine, and laser cutting machines) and techniques that can improve efficiency and product quality.

Reputation: Hochuen have built a strong reputation for reliability, quality, and customer service for offer better service to clients of medical device industry.We have established long-term relationships with more than 2000 clients based on trust and proven performance.

For packing, we can use inner plastic bags with foam, and outer cardboard boxes or wooden case with great protect to avoid any vibration. We can also use customized packages according to customer's requirements.

1. What kind of printing you can do?

We have silkscreen printing, pad printing, digital printing, UV printing, off-set printing, laser printing. (Including automatic printing, semi-auto printing, etc.)

2. How do you cut the parts?

We have laser cutting, die cutting, CNC machining and stamping.

3. What Certificate do you have?

We have certified with ISO 9001, ISO 14001, ISO 45001, and ISO 13485.

4. What tons of injection molding machine do you have?

From 50 tons to 450 tons, we mainly focus on consumable medical device, LSR (liquid silicone rubber) also available, and we do mold in house.

5. How do you assemble the parts?

Typically we have PSA bonding, laser welding, ultrosonic welding, diffusion bonding,

etc.

6. Are you available only prototyping or from prototyping to manufacturing?

We are an OEM manufacturer, and provide one stop service from prototyping to mass production.

All of our products are customized.

Похожие товары

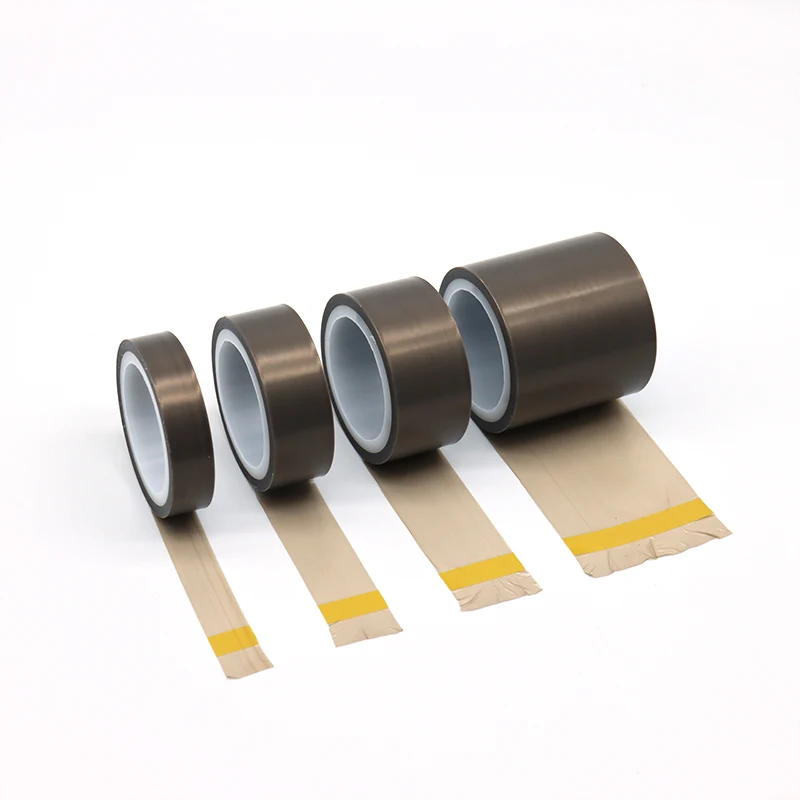

Термостойкое покрытие, ткань из стекловолокна, высокотемпературный силиконовый клей Ptfe тефлоннинг

Клейкая термостойкая лента Tygaflor

Двусторонняя прочная клейкая лента для настенных поверхностей оптом, бесплатные образцы

Двухсторонняя прозрачная пленка Tesa 4928 125um

Самоклеящаяся белая Маскировочная лента для домашней живописи общего назначения из крепированной бумаги

Китайская фабрика, черный свет, реактивная неоновая ткань, гафферная лента для дня рождения, светящаяся вечеринка

60760 ПВХ желтая лента для пола

Новые поступления

Новинки товаров от производителей по оптовым ценам