Автоматическая машина для выпрямления и резки стальной проволоки высокоскоростное выпрямление резание (80 110 мм/мН)

- Категория: >>>

- Поставщик: Hebei Kaiye Machinery Equipment Co. Ltd.

Сохранить в закладки 1601267510149:

Описание и отзывы

Характеристики

Overview

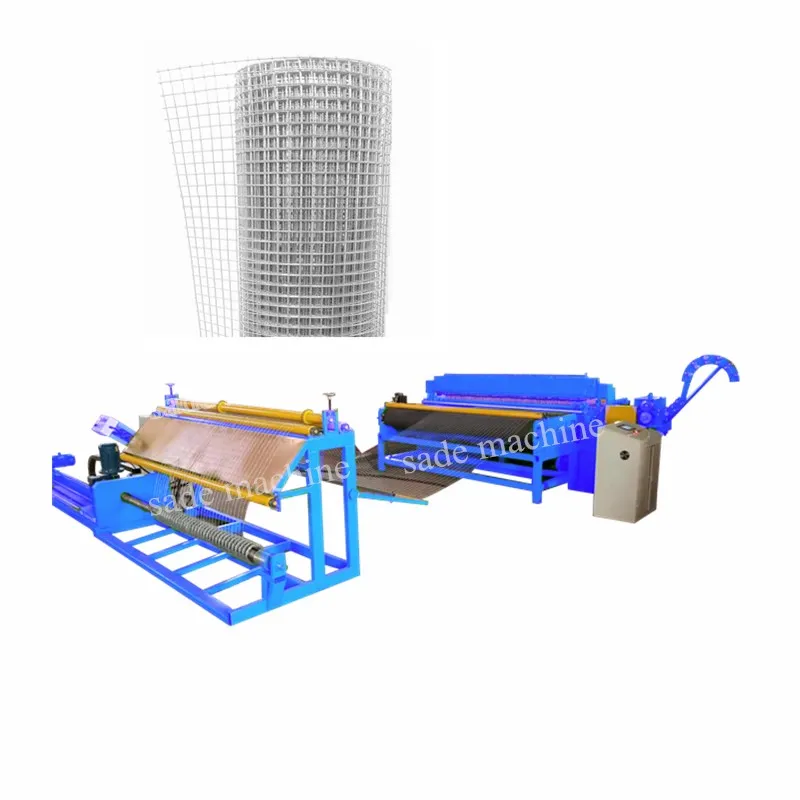

High productive Semi-automatic wire mesh panel welding machine for fence mesh, can be used for low carbon, galvanized, black steel wires.

After the automatic welding machine, the factory newly developed the semi-automatic wire mesh panel welding machine in 2022 according to the customer's demand. This machine is an economical, good price and practical machine. It is widely welcomed by customers because of its simple operation, low mechanical cost and easy maintenance.

Machine Features

Main features of the semi automatic wire mesh panel welding machine.

The welding control system uses synchronized control with digital circuits to manage welding time and processes. The weft wire is fed using a rotating table and a stepping motor for automatic and precise feeding. The welded mesh does not require cutting—vertical wires are placed by hand, and there are no limits on the mesh length. A servo motor controls the pulling of the mesh, allowing for easy adjustments and accurate sizing. The machine can weld a variety of grid types and different mesh settings can be used. It features a new transformer that can weld wires of various thicknesses with a wide voltage range. Both simultaneous and partial welding do not interfere with other electrical devices.

Size Information

Model | KY-MWM-2000 | KY-MWM-2500 | KY-MWM-3000 |

Mesh width | Max.2000 mm | Max.2500 mm | Max.3000 mm |

Mesh hole size | 50 mm 100 mm 150 mm 200 mm 300 mm | 50 mm 100 mm 150 mm 200 mm 300 mm | 50 mm 100 mm 150 mm 200 mm 300 mm |

Wire diameter | 3.0-5.0 mm | 3.0-5.0 mm | 3.0-5.0 mm |

Welding speed | 40-80 Times/min | 40-80 Times/min | 40-80 Times/min |

Transformer | 125KVA*5 | 125KVA*6 | 125KVA*8 |

Dimensions | 6.5 X 2.5 X 1.65 m | 6.5 X 3.0 X 1.65 m | 6.5 X 3.5 X 1.65 m |

Weight | 4500 KG | 5500 KG | 6500 KG |

Detailed Images

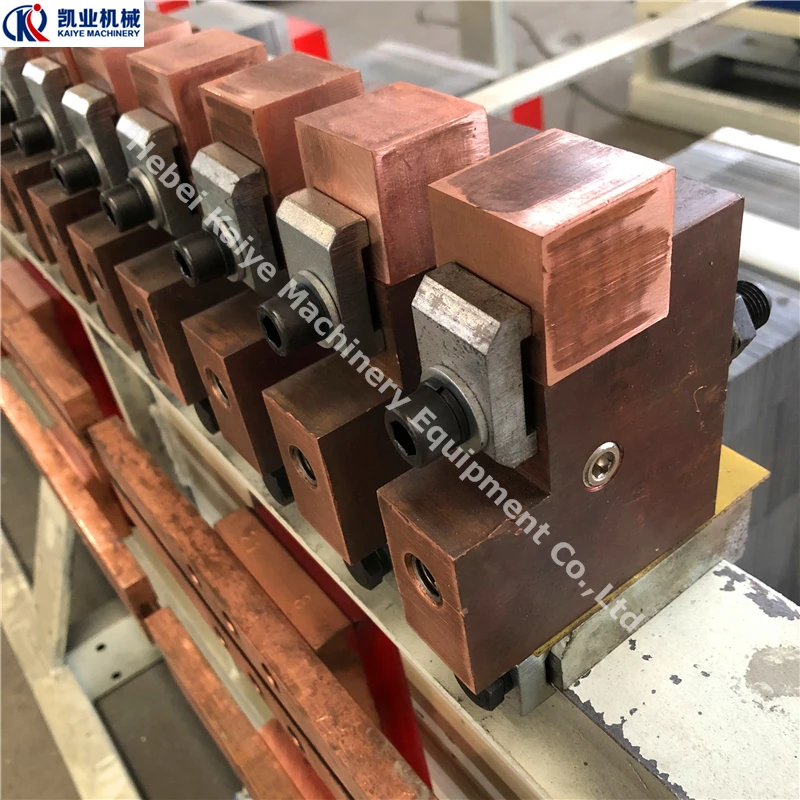

Welding electrode.

The upper and lower welding electrodes have long service life because they are made of high chromium copper.

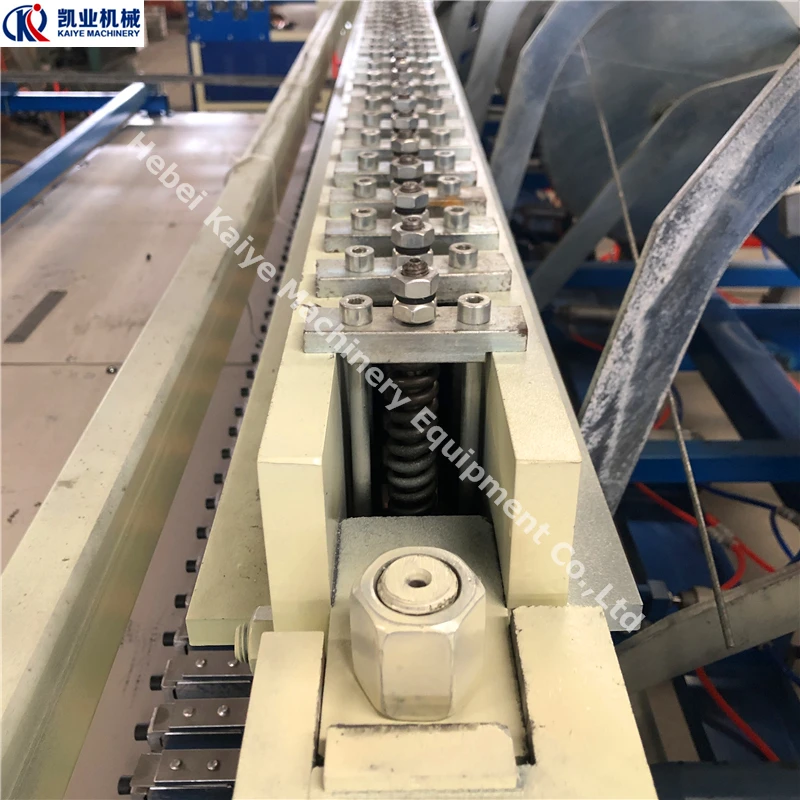

Wire inlet device.

The positioning of the wire inlet device is accurate, which can easily move the position and change the grid size.

Welding transformer.

Welding transformer uses high-quality water-cooled transformer to improve the running time of machinery.

Connecting copper plate.

The connection between transformer and electrode uses copper plate instead of copper wire, which has better conductivity.

Hold mesh hook.

Hold mesh hook adopts cylinder power, which has better effect and faster and more accurate action.

Pull mesh system.

The mesh pulling system adopts servo motor, which can make the mesh more standard and accurate.

Cross wire Blanking system.

The cross wire blanking system adopts a new design, which makes the wire blanking more accurate and improves the mechanical production efficiency.

Cross wire trolley.

The cross wire trolley can be moved, which is convenient for customers to change the mesh size, and the machinery is more reasonable.

Finished photos

Contact me

Packing and Shipping

Certifications

Market and Customers

Friends from all over the world.

The company's machinery and equipment sell well in China, and are exported more than 100 countries and regions such as Romania,Lithuania, Turkey, Poland, Belarus, Ukraine, Russia, Kazakhstan, Saudi Arabia, Egypt, Algeria, South Africa,Vietnam, Thailand,India, Pakistan, Philippines, Indonesia, Australia, Mexico, Colombia, Argentina, Bolivia, Brazil, etc.

After more than ten years of development, the company has grown into one of the leading enterprises in the industry. We adhere to the tenet of "customer first, technology leading". In the future, the company will comprehensively promote industrial development and upgrading, and build the world's leading steel processing equipment.

After more than ten years of development, the company has grown into one of the leading enterprises in the industry. We adhere to the tenet of "customer first, technology leading". In the future, the company will comprehensively promote industrial development and upgrading, and build the world's leading steel processing equipment.

FAQ

Q:What types of wire your machine can weld wire?

A:black wires,iron wires,galvanized wires.

Q:How to adjust the welding mesh size?

A:Adjust the size of the electrodes, adjust the speed of the cross wire hopper.

Q:How to adjust the speed of the wire mesh welding machine?

A:Through the contrl cabinet.

A:Through the contrl cabinet.

Q: Are you a trading company or manufacturer?

A: Our company is a factory integrating production and sales. We can provide competitive prices and services.

Q:Where is your factory located?

A: Our factory is located in Anping county, Hebei Province of China. The nearest airport is Beijing airport or Shijiazhuang airport. We can pick you up from Shijiazhuang airport.

Q: How many years is your company engaged in the wire mesh machines?

A: More than 20 years. We have our own technology develop department and testing department.

Q: Can your company send your engineers to my country for machine installation, worker training?

A: Yes, our engineers went to more than 60 countries before. They are very experienced.

Q: Can you export and supply the customs clearance documents we need?

A: We have much experience for exporting. And we can supply the CE certificate, Form E, passport, SGS report etc, your customs

clearance will be no problem.

A: Our company is a factory integrating production and sales. We can provide competitive prices and services.

Q:Where is your factory located?

A: Our factory is located in Anping county, Hebei Province of China. The nearest airport is Beijing airport or Shijiazhuang airport. We can pick you up from Shijiazhuang airport.

Q: How many years is your company engaged in the wire mesh machines?

A: More than 20 years. We have our own technology develop department and testing department.

Q: Can your company send your engineers to my country for machine installation, worker training?

A: Yes, our engineers went to more than 60 countries before. They are very experienced.

Q: Can you export and supply the customs clearance documents we need?

A: We have much experience for exporting. And we can supply the CE certificate, Form E, passport, SGS report etc, your customs

clearance will be no problem.

Похожие товары

Электросварочная машина evg

Фабрика Китая 5-12 мм машина для сварки арматурной сетки

35 000,00 $ - 65 000,00 $

Высокоскоростной односпальный и двойной Проволочный Кабель хорошего качества, полностью автоматическая машина для забора звеньев цепи

5 500,00 $ - 6 000,00 $

Машина для производства листового металла из нержавеющей стали

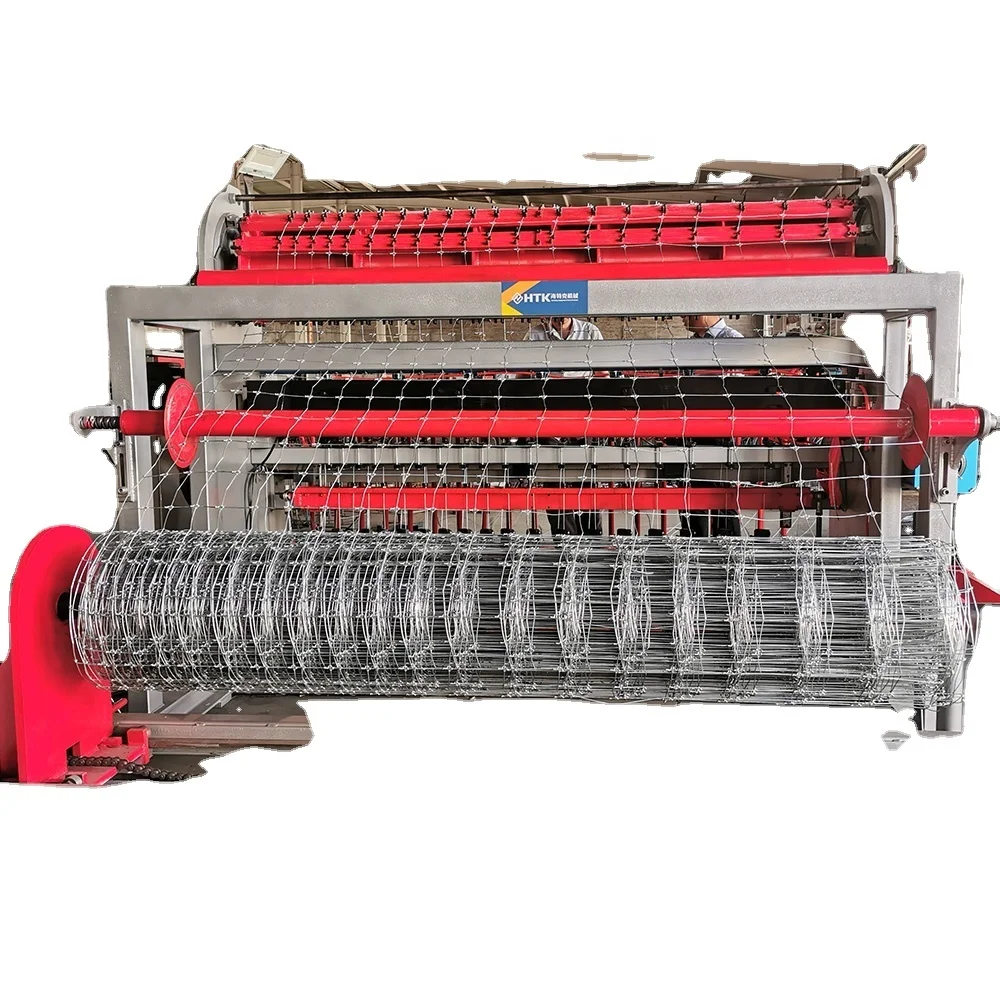

Высококачественная новая улучшенная автоматическая машина для ограждения поля/машина для ограждения пастбищ/машина для ограждения с фиксированным узлом с новой технологией

65 000,00 $ - 85 000,00 $

Алмазная проволочная сетка делая машину полу-Авто цепь ссылка забор машина

Сталь сплющения Расширенная металлическая сетка делая машины

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $