Премиум промышленные керамические инертные формованные шарики термостойкие сферы SIO2 материал огнеупорные применения штамповочная обработка

- Категория: >>>

- Поставщик: Pingxiang Jianghua Equipment Packing Co. LTD

Сохранить в закладки 1601267810435:

Описание и отзывы

Характеристики

Product Description

Product Overview

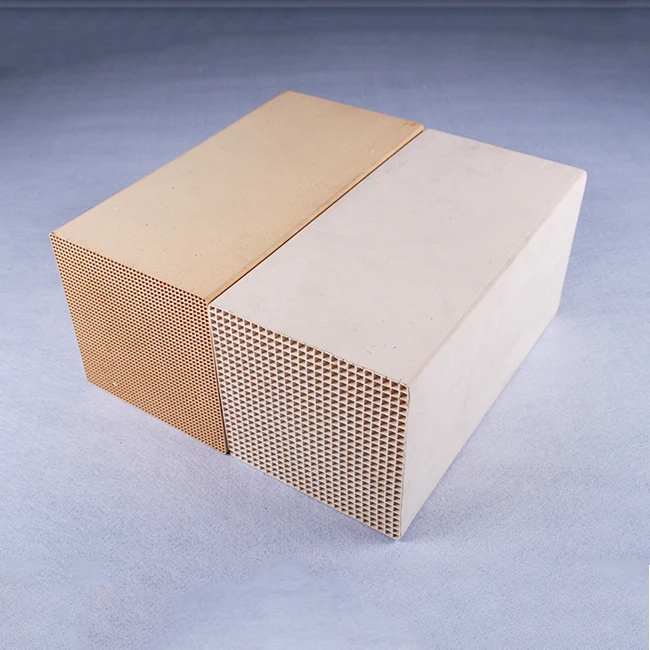

Inert Ceramic Balls are widely used in industrial applications as support and packing materials. Made from high-quality ceramic, they offer excellent thermal, mechanical, and chemical stability. Their primary role is to act as a support medium in catalyst beds, mass transfer operations, and various separation processes in industries such as petrochemicals, chemicals, and refining.

Product Applications

Catalyst Support in Chemical Reactors: Used as a base layer in catalytic reactors to support and protect the catalyst.

Tower Packing for Distillation and Absorption: Enhances mass transfer in distillation columns, absorption towers, and stripping processes.

Heat Transfer Media: Suitable for high-temperature applications, such as in regenerative heat exchangers.

Gas and Liquid Distribution: Facilitates uniform distribution of gases and liquids in packed bed reactors.

Filtration Media: Acts as a support layer in industrial filtration processes, such as water treatment and gas scrubbing.

Catalyst Support in Chemical Reactors: Used as a base layer in catalytic reactors to support and protect the catalyst.

Tower Packing for Distillation and Absorption: Enhances mass transfer in distillation columns, absorption towers, and stripping processes.

Heat Transfer Media: Suitable for high-temperature applications, such as in regenerative heat exchangers.

Gas and Liquid Distribution: Facilitates uniform distribution of gases and liquids in packed bed reactors.

Filtration Media: Acts as a support layer in industrial filtration processes, such as water treatment and gas scrubbing.

Specification

Inert Ceramic Balls

Physical and Chemical Properties

Technical Indicators | Material Type | Inspection Method | ||||||||||

Ordinary | Low Alumina | Medium Alumina | High Alumina | Corundum | ||||||||

Chemical Composition,% | Al2O3 | 20~30 | 31~45 | 46~70 | 71~90 | ≥90 | GB/T 4734-1996 | |||||

Al2O3+SiO2 | ≥90 | GB/T 4734-1996 | ||||||||||

Fe2O3 | ≤1 | GB/T 4734-1996 | ||||||||||

Water absorption rate,% | ≤5 | HG/T 3210-2002 | ||||||||||

Acid resistance,% | ≥90 | HG/T 3210-2002 | ||||||||||

Alkali Resistance,% | ≥85 | HG/T 3210-2002 | ||||||||||

Thermal Shock Resistance,℃ | ≥300 | HG/T 3210-2002 | ||||||||||

Maximum Heat Resistance Temperature,℃ | 1000 | 1200 | 1300 | 1400 | 1500 | HG/T 3683.1-2014 | ||||||

Bulk density,kg/m3 | 1300~1400 | 1400~1500 | 1500~1600 | 1600~1800 | ≥1800 | For Reference Only | ||||||

Compressive Strength (KN per Ball)

Diameter (mm) | Type | Ordinary | Low Alumina | Medium Alumina | High Alumina | Corundum | |

Al2O3,% | 20~30 | 31~45 | 46~70 | 71~90 | ≥90 | ||

Ф3mm | ≥0.20 | ≥0.25 | ≥0.30 | ≥0.35 | ≥0.40 | ||

Ф6mm | ≥0.50 | ≥0.60 | ≥0.65 | ≥0.70 | ≥0.80 | ||

Ф8mm | ≥0.70 | ≥0.80 | ≥0.90 | ≥1.00 | ≥1.20 | ||

Ф10mm | ≥0.85 | ≥1.00 | ≥1.20 | ≥1.50 | ≥1.90 | ||

Ф13mm | ≥1.80 | ≥2.30 | ≥3.00 | ≥4.00 | ≥5.80 | ||

Ф16mm | ≥2.30 | ≥3.00 | ≥4.50 | ≥6.00 | ≥7.00 | ||

Ф20mm | ≥4.30 | ≥5.00 | ≥6.00 | ≥7.50 | ≥9.00 | ||

Ф25mm | ≥6.20 | ≥7.00 | ≥8.00 | ≥10.00 | ≥12.00 | ||

Ф30mm | ≥7.00 | ≥8.00 | ≥10.00 | ≥12.00 | ≥14.00 | ||

Ф38mm | ≥8.80 | ≥10.00 | ≥12.00 | ≥16.00 | ≥18.00 | ||

Ф50mm | ≥12.00 | ≥13.00 | ≥15.00 | ≥18.00 | ≥21.50 | ||

Ф76mm | ≥16.00 | ≥18.00 | ≥20.00 | ≥22.00 | ≥25.00 | ||

item | value |

Place of Origin | Jiangxi,China |

Brand Name | JH |

Product name | Inert Ceramic Balls |

Material | Al2O3 |

Water Absorption | ≤5% |

Acid Resistance | ≥90% |

Alkali Resistance | ≥85% |

Thermal Shock Resistance | ≥300℃ |

Maximum Heat Resistance | 1500℃ |

Bulk Density | 1300~1800 kg/m³ |

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

Our company is a professional chemical packing manufacturer which can develop, design, produce and install products. Our company is the cooperative network member unit of China Petroleum & Chemical Corporation and the Supplier Member Company of Sinopec Group Company.

Our company can produce a series of tower inner parts with ceramics, metals and plastics, water treatment filters, catalysts, Protective agents, Adsorbents and Accessories of Anticorrosive insulation engineering.

Our company has passed GB/T19001-2008 and ISO9001:2008 Certifications. In order to ensure the quality of our products, we established a research laboratory center with 8 researchers, equipped with digital display type engineering ceramic compressive strength testing machines, flame photometers, electronic analytical balances, silicate chemical composition analyzers, electric thermostatic drying ovens, rapid heating furnaces, rapid grinding machines, resistance to chemical corrosion test devices, electronic test furnaces, abrasion testers, etc. Our research laboratory center can meet the needs of all products' research and development and performance tests.

Our products are in strict accordance with the quality management system standards of GB/T19001-2008 and ISO9001:2008. Each batch of our products comply with the strict requirements of our Testing Center Laboratory to test chemical compositions, size deviations, appearance requirements, Compressive strength, Water absorption rate, Acid resistance, alkali resistance, etc.

Our products are sold in more than 20 provinces in China and are especially sold to Sinopec, China Petroleum and China Chemical Industry Group. Some of our products are exported to America, Europe and Asia.

Our company always adheres to the tenet of "quality first, user first, thoughtful services", hoping to do business with all customers from at home and abroad.

Our company can produce a series of tower inner parts with ceramics, metals and plastics, water treatment filters, catalysts, Protective agents, Adsorbents and Accessories of Anticorrosive insulation engineering.

Our company has passed GB/T19001-2008 and ISO9001:2008 Certifications. In order to ensure the quality of our products, we established a research laboratory center with 8 researchers, equipped with digital display type engineering ceramic compressive strength testing machines, flame photometers, electronic analytical balances, silicate chemical composition analyzers, electric thermostatic drying ovens, rapid heating furnaces, rapid grinding machines, resistance to chemical corrosion test devices, electronic test furnaces, abrasion testers, etc. Our research laboratory center can meet the needs of all products' research and development and performance tests.

Our products are in strict accordance with the quality management system standards of GB/T19001-2008 and ISO9001:2008. Each batch of our products comply with the strict requirements of our Testing Center Laboratory to test chemical compositions, size deviations, appearance requirements, Compressive strength, Water absorption rate, Acid resistance, alkali resistance, etc.

Our products are sold in more than 20 provinces in China and are especially sold to Sinopec, China Petroleum and China Chemical Industry Group. Some of our products are exported to America, Europe and Asia.

Our company always adheres to the tenet of "quality first, user first, thoughtful services", hoping to do business with all customers from at home and abroad.

FAQ

1. who are we?

We are based in Jiangxi, China, start from 2002,sell to South Asia(14.29%),Northern Europe(14.29%),Africa(14.29%),Southeast Asia(14.29%),Eastern Europe(14.29%),South America(14.29%),North America(14.29%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

ceramic balls,molecular sieves,Activated Alumina

4. why should you buy from us not from other suppliers?

The company's technical team has over 20 years of experience in the chemical packing industry.

5. what services can we provide?

Accepted Delivery Terms: FOB;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,L/C,PayPal;

Language Spoken:English

We are based in Jiangxi, China, start from 2002,sell to South Asia(14.29%),Northern Europe(14.29%),Africa(14.29%),Southeast Asia(14.29%),Eastern Europe(14.29%),South America(14.29%),North America(14.29%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

ceramic balls,molecular sieves,Activated Alumina

4. why should you buy from us not from other suppliers?

The company's technical team has over 20 years of experience in the chemical packing industry.

5. what services can we provide?

Accepted Delivery Terms: FOB;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,L/C,PayPal;

Language Spoken:English

Похожие товары

Активированный инертного глинозем Catalyst поддерживают СМИ фильтр для воды 23-26% керамический шарик

Оптовая продажа инертной керамической глинозема мяч катализатора поддержки СМИ керамический шарик

99.7% глиноземная керамическая трубка высокой

5,00 $ - 50,00 $

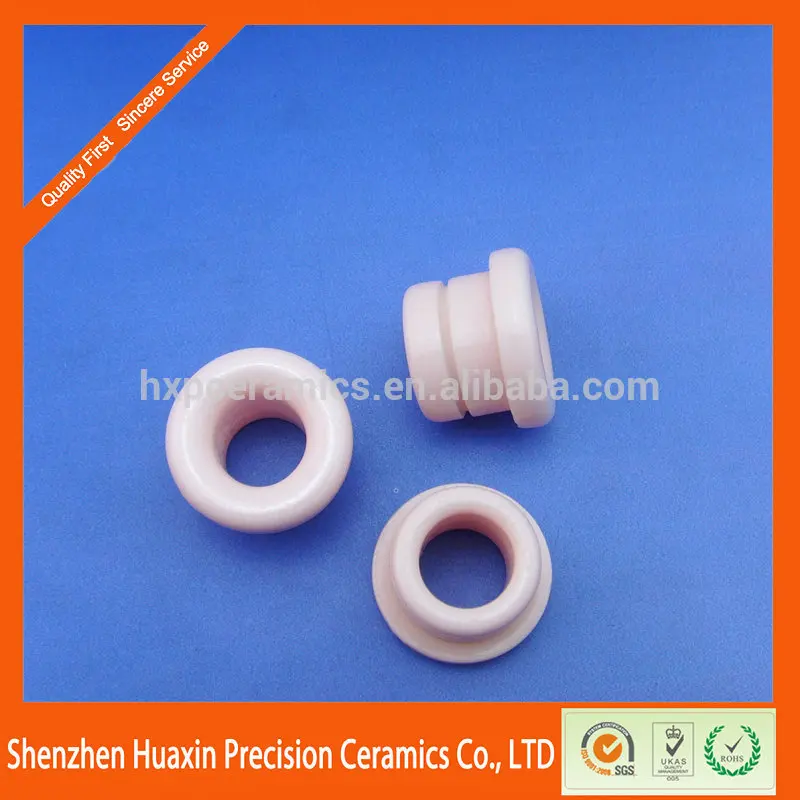

Керамические люверсы, текстильные керамические люверсы

95% алюминиевые детали/керамические люверсы/проволочные направляющие для проволоки/текстиля

95% глинозема части/керамические проушины/керамической руководства провода для провода/текстильной

Керамические легкие цементные износостойкие пластины

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $