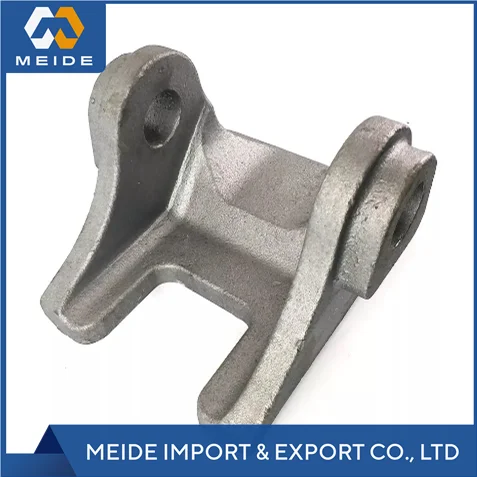

Кованая углеродистая сталь Q195 Q215 Q235 Q255 детали рулевого кулака

- Категория: >>>

- Поставщик: Shandong Meide Import And Export Co. Ltd.

Сохранить в закладки 1601268027862:

Описание и отзывы

Характеристики

Product specification

Product Name | Custom Manufacturing Forging Service |

Quotation | According To Your Drawing(Size /Material/Required Technology /Etc |

Drawing Formats | 2D(PDF/CAD)And 3D(STP/STEP) |

Materials | Aluminum/Stainless Steel/Steel/Brass /Copper /Plastic /Iron/Alloy /Zinc/Etc. Other Special Materials:Nylon/Titanium/Lucite/Etc. |

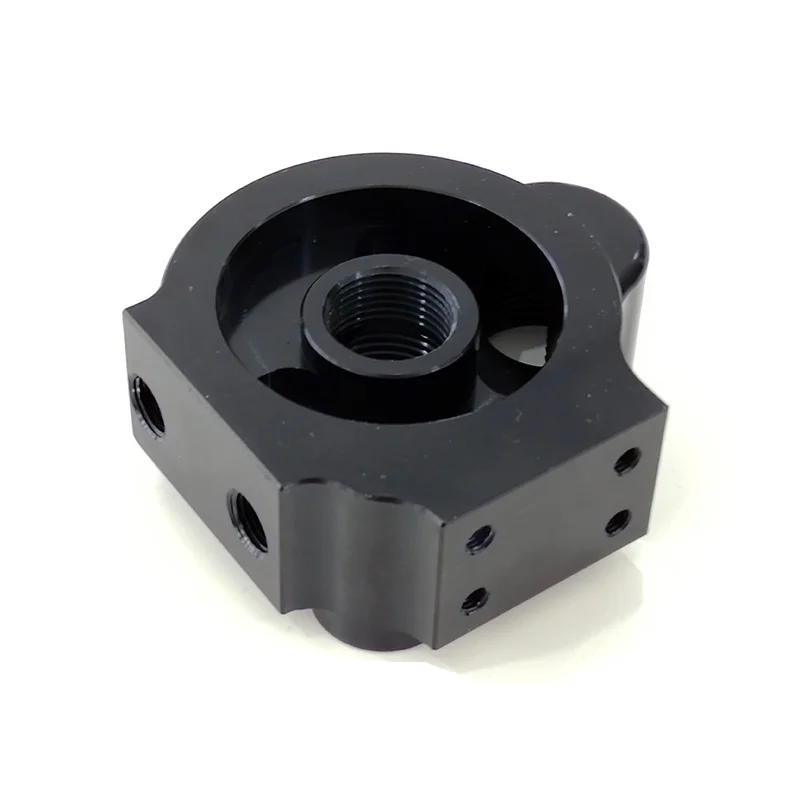

Main Process | CNC Turning /Milling /Drilling/Bushing /Auto Lathe /Surface Treatment /Etc. |

Tolerance | ±0.02MM |

Surface Roughness | Ra0.4(milled or turned without polishing or grinding) |

Finish | polishing,mirror polishing,brushing,sandblasting,heat treatment etc. |

Surface Treatment | anodizing,blackening,electroplating(zinc,nickel,chrome),electrophoresis, painting,powder coating,passivate,carburize etc. |

Logo | laser engraving,CNC engraving,screen-printing etc. |

Forging classification and characteristics

Classification by processing temperature: cold forging, warm forging, hot forging

Classification by structure: forgings with the main axis standing in the die forming (such as gear), forgings with the main axis lying in the die forming (such as connecting rod), forgings with the main axis winding (such as automobile steering knuckles)

High density, high strength, good wear resistance, good corrosion resistance, no defects, long life.Classification by structure: forgings with the main axis standing in the die forming (such as gear), forgings with the main axis lying in the die forming (such as connecting rod), forgings with the main axis winding (such as automobile steering knuckles)

Common forging products are forging shaft, forging ring, forging plate, forging flange, forging sleeve

Product Feature

2. Wide range of products, fast sampling and prompt delivery.

3. Precision forging and CNC Machining as per customer;s drawings.

4. Precise tolerance as per request.

5. Varieties of surface finish can meet customer's need.

6. Full inspection before shipment.

Product application

Widely used in construction machinery, automobiles, ships, aerospace, metallurgy, electric power and other fields Gear forgings are mainly used in mining machinery, petrochemical, automobile manufacturing and other industries, of which automobile forgings account for a large proportion

Product Display

Forged parts for shipping and Marine:

Forged Shaft for Shipbuilding,Shaft ,Shaft Couplings,FWD BOSS,AFT BOSS,ABS Gear Blanks,ABS Marine Shafts (All types),Rudder

Marine-Diesel engine:

Mill Frequently Used Steel Materials:

Forged Shaft for Shipbuilding,Shaft ,Shaft Couplings,FWD BOSS,AFT BOSS,ABS Gear Blanks,ABS Marine Shafts (All types),Rudder

Marine-Diesel engine:

piston rod, Cylinder Cover blank, connecting rod, Chain wheel, crankshaft, crosshead

Other forgings also available

FOR DIESEL ENGHINE

Other forgings also available

FOR DIESEL ENGHINE

major material for diesel engine

S17MoS, S30MnH, S45SU, S30S, S18CrNiMo, S20CrMoVS, S20CrMoVS, S30MnH, S42Cr1S, S45SU, S30S , S19R, etc

FOR OTHER FORGINGS

Material: Carbon Steel, Alloy Steel, Tool steel, Stainless steel

Standard: DIN, ASTM, GB, JIS related ones

Piece weight: no more than 20tons

Ring: outer diameter no more than 3500mm

Shaft Length: No more than 10 meter

All different forging products as per customer drawing

S17MoS, S30MnH, S45SU, S30S, S18CrNiMo, S20CrMoVS, S20CrMoVS, S30MnH, S42Cr1S, S45SU, S30S , S19R, etc

FOR OTHER FORGINGS

Material: Carbon Steel, Alloy Steel, Tool steel, Stainless steel

Standard: DIN, ASTM, GB, JIS related ones

Piece weight: no more than 20tons

Ring: outer diameter no more than 3500mm

Shaft Length: No more than 10 meter

All different forging products as per customer drawing

Mill Frequently Used Steel Materials:

1) Wind Power Shaft: 42CrMo4V, 34CrNiMo6; Wind Power Flange: S355NL, C22, 16Mn, 20Mn, 42CrMo, F304.

2) Forged Pipe Fittings: SA106 CL B, SA106 CL C, WB36, 12Cr1MoV, SA335 P11, P12, P22, P91, SA182 Gr.F1, Gr.F5, Gr.F11 CL2, Gr.F12

CL2, Gr.F22 CL3, SA350 Gr.LF1, Gr.LF2,

Gr.LF3.

3) Pressure Vessel Forgings: SA105, SA350 LF2, 16Mn, 20MnMo, 15MnMo, 12Cr2Mo1, 14Cr1Mo, F304, F316, 17-4PH.

4) Shaft Related Forgings: 25CrMo4, 42CrMo4, 40CrNiMo, 34CrNi3Mo, 25Cr2Ni4MoV, 18CrNiMo5, 30CrMo, 4130, 4140.

5) Gear Related Forgings: 35CrMo, 34CrMo4, 4137, 42CrMo, 4140, SCM440, 20CrMnMo, 40CrNiMo, 20CrNi2Mo, 20Cr2Ni4A, 34CrNi3Mo.

6) Copper Forgings: C10100, C10200, C10300, C10700, C12000, C12200.

2) Forged Pipe Fittings: SA106 CL B, SA106 CL C, WB36, 12Cr1MoV, SA335 P11, P12, P22, P91, SA182 Gr.F1, Gr.F5, Gr.F11 CL2, Gr.F12

CL2, Gr.F22 CL3, SA350 Gr.LF1, Gr.LF2,

Gr.LF3.

3) Pressure Vessel Forgings: SA105, SA350 LF2, 16Mn, 20MnMo, 15MnMo, 12Cr2Mo1, 14Cr1Mo, F304, F316, 17-4PH.

4) Shaft Related Forgings: 25CrMo4, 42CrMo4, 40CrNiMo, 34CrNi3Mo, 25Cr2Ni4MoV, 18CrNiMo5, 30CrMo, 4130, 4140.

5) Gear Related Forgings: 35CrMo, 34CrMo4, 4137, 42CrMo, 4140, SCM440, 20CrMnMo, 40CrNiMo, 20CrNi2Mo, 20Cr2Ni4A, 34CrNi3Mo.

6) Copper Forgings: C10100, C10200, C10300, C10700, C12000, C12200.

Company Profile

Shandong Meide Import and Export Co., LTD was established in 1997. Located in Liaocheng City, Shandong Province, the largest steel logistics center in North China, focusing on the production and sales of copper, aluminum, stainless steel, special steel, mould steel, alloy steel, steel processing machinery and equipment. Our products are mainly extended to five series of plate, strip, tube, bar and profile. We have passed ISO9001:2000 quality system certification, SGS, ROSH, TUV and REACH certification. Has cold rolling, hot rolling and other production lines. Such as heat treatment chemical analysis, metal halide testing, physical testing, nondestructive testing and other testing equipment and testing technology, imported physical and chemical testing equipment full spectrum direct reading spectrometer, can quickly and accurately chemical analysis of all kinds of metal materials. According to American ASTM standard, Japanese JIS standard, German DIN standard, British BS standard and other standards production. At the same time, we can customize and develop new products according to the actual application of customers, and provide products for different cost and performance requirements. The company cooperates with more than 20 well-known steel mills in China, and has established modern large outdoor warehouse and indoor warehouse, with 20,000 tons of goods in stock. The customer base covers all provinces and cities in China, and has more than 100 long-term stable cooperative customers. We warmly welcome and look forward to cooperating with you!

Production Process

The production process of forging mainly includes material selection, heating, forging deformation, cooling, follow-up treatment and inspection steps. First, the metal material suitable for forging is selected and heated to improve its malleability. The material is then plastically deformed on a forging device to form the desired shape. Next, the forged material is cooled. After that, subsequent processing such as trimming and punching may be required to meet dimensional requirements. Finally, through strict inspection to ensure the quality of forging, qualified before storage. The entire production process must strictly follow the process requirements to ensure the high quality and performance of the forging.

Certification

Packaging and Transportation

FAQ

1.Q:What is the future of forging?

A:As reported by IQS Engineering Solutions, the metal forging market is expected to reach USD 130.51 billion by 2028 and grow 6.34% between 2021 and 2028 due to an increased demand for advanced and high-strength components to be used in many industries.

A:As reported by IQS Engineering Solutions, the metal forging market is expected to reach USD 130.51 billion by 2028 and grow 6.34% between 2021 and 2028 due to an increased demand for advanced and high-strength components to be used in many industries.

2.Q:What material is good for forging?

A:Forging is a process that accepts a wide variety of materials,the most common are: carbon steel, alloy steel, stainless steel, duplex and aluminum alloys, titanium, nickel, copper and brass.

3.Q:What are the forging technology?

A:Free forging, die forging, ring rolling, special forging. According to the forging temperature, it can be divided into hot forging, warm forging and cold forging.

4.Q:What is the difference between CNC and forging?

A:Forging produces significantly stronger parts than CNC machining.

5.Q:Why is forging better than welding?

A:In side by side testing, forging offers consistently improved performance and strength when compared to welding.

Похожие товары

Индивидуальная ковка и обработка, Автомобильное оборудование для мотоцикла, поршневые аксессуары из алюминиевого сплава, ковочные детали

Кованый поршень для мотоцикла Высокое Качество Ковки услуги продукт

Высокое качество на заказ полировка алюминиевый горячий кованый велосипед тормозные суппорты ковка часть

X348 X458 X678 кованая навесная однорельсовая конвейерная тележка Монорельсовая конвейерная тележка, кованые стальные детали

10,94 ₽

Высокоточный кованый стальной вал для повышения эффективности оборудования

2 187,87 ₽

Высокопроизводительные поворотные компоненты Nanjing, стальная ковка, обработка с ЧПУ, Резьбовая втулка с e-покрытием

14H2GMR кованые трубы металлические втулки для паровой турбины направляющее кольцо

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $