Полностью Автоматическая односторонняя машина для очистки DEZ C758 печатной платы Silman производственной линии SMT

- Категория: >>>

- Поставщик: Shenzhen Silman Technology Co. Ltd.

Сохранить в закладки 1601268316665:

Описание и отзывы

Характеристики

Specification

Model: | DEZ-C758 |

Dimention: | L1860*W850*H1200mm ±20mm |

Weight: | 400KG |

PCB Width (Adjustable): | 50-300mm |

PCB Height (Adjustable): | PCB Height (Adjustable): 750±50mm |

PCB Speed: | 0-1800mm/Min |

PCB Board Direction: | L→R/ R→L(Optional) |

PCB Component height restrictions | Max135mm |

Coating roller size | φ100mm |

Disc brush size | φ300 |

Brush height adjustment range | 0-20mm adjustable |

Applicable cleaning agent type | Environmentally friendly cleaners |

Dry way | Air drying |

Liquid storage tank capacity | Max 20 L |

Cleaning agent flow rate | 50-1500ml/min |

Complete machine control method | PLC+button |

Power Supply | 2 Phase 3 wires |

Total Power: | 1KW |

Working comsumption: | 0.4KW |

Transport connection height : | 750±20mm |

Exhaust volume requirements : | 10M³/min (Tunnels) |

Spindle speed | 0-500 rpm (continuously variable)) |

Working Voltage: | 220V 50HZ |

Transmission speed : | 0.05~1.8m/min |

Product Introduction

C758 PCBA Fully Automatic Single Side Cleaning Machine

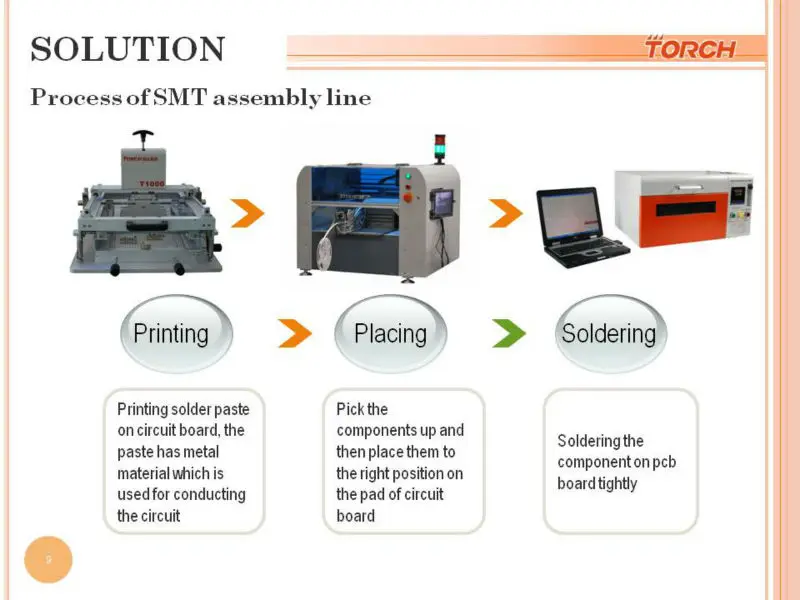

C758 series fully automatic PCBA board cleaning machine is an online type automatic cleaning machine specifically designed for PCBA boards. It is suitable for traditional board washing water, eliminating the need for manual contact with cleaning agents. This equipment combines PCBA board transmission technology with brush cleaning technology, enabling multi-directional brushing from front, back, left, and right directions, ensuring thorough cleaning without any blind area and meeting the cleanliness requirements of PCBA boards. It is suitable for cleaning single-sided PCBA board soldering surfaces without wetting the front components.

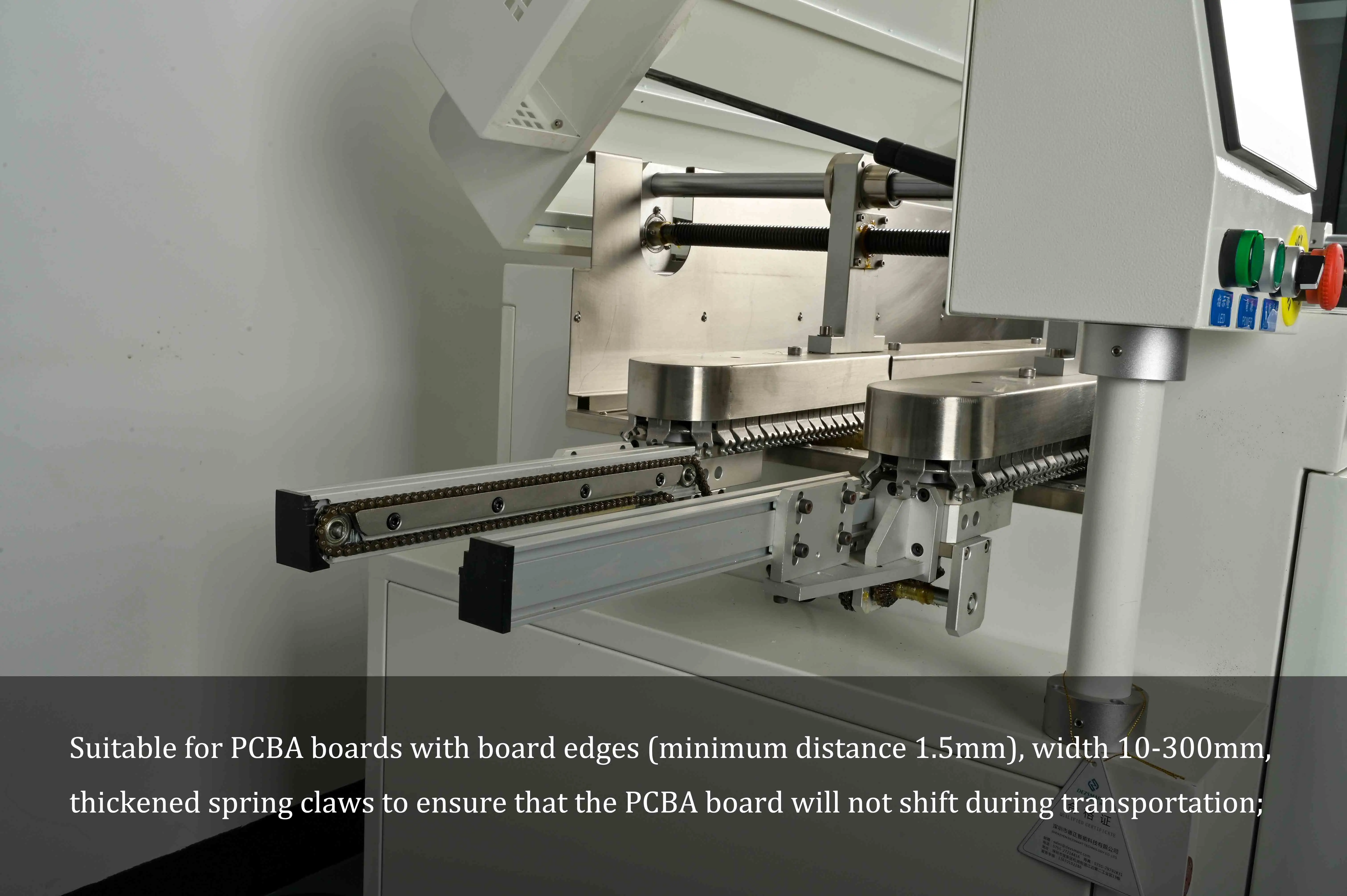

◆Suitable for PCBA boards with board edges (minimum distance 1.5mm), width 10-300mm, thickened spring claws to ensure that the PCBA board will not shift during transportation;

◆ Automatic cleaning agent coating system: ensure that the welding surface of the PCB board can be evenly coated with board washing water without affecting the surface of other parts;

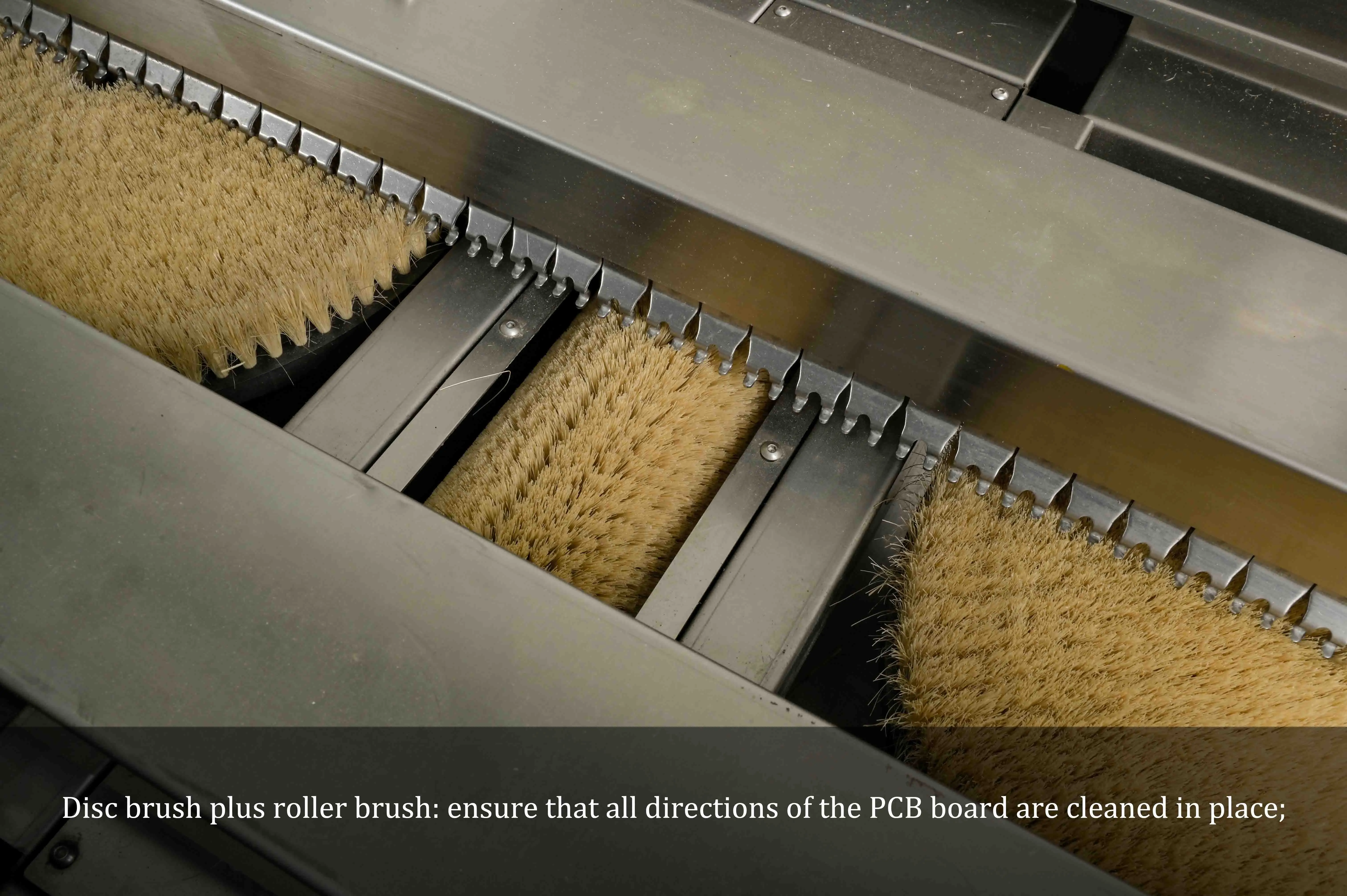

◆ Disc brush plus roller brush: ensure that all directions of the PCB board are cleaned in place;

◆ The height and speed of the cleaning brush (stepless speed change) can be adjusted to meet

different cleaning needs;

different cleaning needs;

◆ The waste generated during work is automatically gathered in the filter box at the bottom of the machine for easy cleaning;

◆ Powered by 220 volts. Easy to use

Packaging

Buyer Show

Company Profile

Certificate

FAQ

1.Does Silman have its own factory?

Yes, our factory is located in Shenzhen, Guangdong, China. We have been engaged in machine production for more than ten years. Among them, bonding machines, laser machines, BGA rework stations and other machines and related consumables are our core competitive products, which have been favored by the market and buyers in recent years and have been well received.

2.How do you use your machines?

We provide comprehensive free training including SOP materials and have the largest number of trained users. We support face-to-face on-site training and are willing to provide on-site service.

3.What problems can your machine solve?

LCD laser repair machine can solve the problems that COF bonding machine can't solve. Repair all brands of open LED/LCD/OLED TV screens, laptop screens, computer screens and display panels. ITO cutting and welding, color lines,

vertical/horizontal lines, dot/pixel circuits, short circuits, bright dots/lines, GOA circuits and double lines. Repair panels up

to 85 inches, 100 inches (optional)

vertical/horizontal lines, dot/pixel circuits, short circuits, bright dots/lines, GOA circuits and double lines. Repair panels up

to 85 inches, 100 inches (optional)

4.Do your machines have warranty?

Yes, our machines support 1 year warranty and lifetime maintenance. The service life is more than ten years.

5.What is the pixel count of your laser microscope?Microscope and laser focus:

5X, 10X, 20X, and 50X (optional)

Похожие товары

DEZ-C758 печатная плата Silman, односторонняя Чистящая Щетка, машина для очистки печатной платы для производственной линии SMT

744 386,93 ₽ - 809 125,61 ₽

Полуавтоматическая точная смд производства линь машина для шелгографии плетная платы,SMD монтаж устаноавки компонентов,пайка

Оригинальные новые запасные части SMT W12F Фидер 2ADLFB005813 FUJI NXT Интеллектуальный для палочки и

610,00 $

Плата для впрыска AS28A зарядка AS56A зажим AS85A карта инжектора toshiba Shibaura машина литья под

920,00 $ - 990,00 $

FUJI SMT машина NXT H01 сопло FITER с держателем AA1FZ01 фильтр

Высококачественный Печатный конвейер smt, полностью автоматический инверторный конвейер smt pcb, инверторный конвейер

537 277,16 ₽

Полноавтоматический PCB Многофункциональный буферный Конвейер SMT буфера PCB буфера stocker

537 277,16 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $