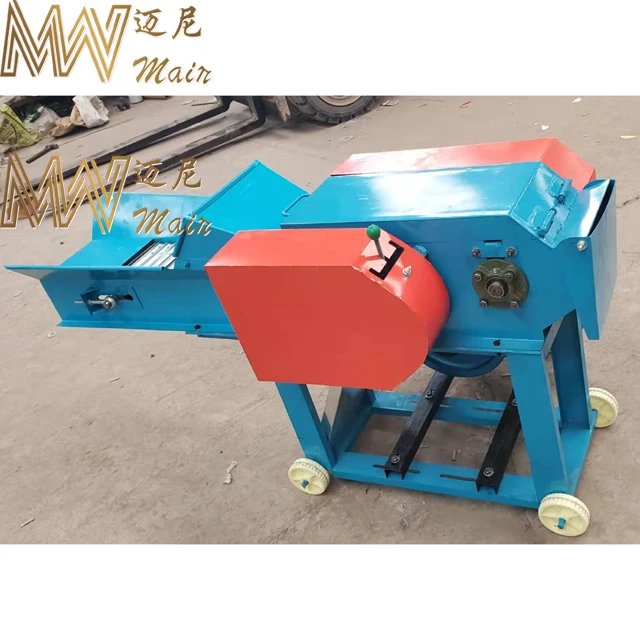

Машина для производства кормов

- Категория: >>>

- Поставщик: Anyang Ainuok Machinery Equipment Co. Ltd.

Сохранить в закладки 1601268467013:

Описание и отзывы

Характеристики

Poultry pig cattle cow sheep chicken feed pellet making machine feed pellet machine pelletizer machine for animal feeds

1.Feed pellet machine (also known as: granule feed machine, feed granule machine, granule feed molding machine), belongs to the feed granule equipment. It is a feed processing machine with corn, soybean meal, straw, grass and rice husk as raw materials and directly pressed into granules after grinding raw materials.Feed pellet machine is widely used in large, medium and small aquaculture, grain feed processing plants, livestock farms, poultry farms, individual farmers and small and medium-sized farms.

2.Electric,Desel engine,PTO drive and Gasoline type are for option,please Send Inquiry to get production details and latest quotation.

RFQ

1.What machine is used to make fish pellets?

Sinking fish feed machinery that directly compels grains from corn, soybean meal, straw, grass, rice husk, etc..

and puff extruder machine is used for making floating fish feed machine

2.What is the price of fish feed making machine in Odisha?

Different specifications, different regions of the price is slightly different, please consult the merchant to get the specific price

Is floating pellets good for fish?

yes,floating fish feed pellet is easy for fish to eat and Does not pollute water

3.Which is better sinking or floating pellets?

Depending on the species of fish, the fish living in the upper waters float fish feed. Bottom water fish are suitable for bottom fish feed

4.What are the advantages of floating fish feed

Soft and easy to digest, does not pollute the water

Raw material

1.sawdust, rice husk,straw, grass,crop stalks etc. biological fertilizer, animal manure

2.Moisture required: 10-15%

3.Size:3-5 mm

Final Pellet:

The Pellet Diameter is Dia 2.5mm, 4mm, 6mm, 8mm, 10mm, 12mm, etc,at option.

1.Widened feed inlet, convenient for feeding

2.Pure copper motor, high power and low noise

3.Coupling rotation, low friction, less transmission ratio loss than belt

4.Stainless steel coupling,high temperature quenching treatment

5.Made of Chromium-manganese steel final shaft and grinding disc, high temperature quenching treatment

6.Length of feed pellets can be adjusted at any time

7.Grinding disc size from 2mm to 12mm for choice

8.Nylon casters, wear-resistant&durable

9.Oil window&oil dipstick, accurately detect the oil level

10.3 layers of spray paint, 20 years anti-rust

11.Adjust the distance between the roller and the disc, keep the nuts on both sides balanced, so as not to damage the pressure roller grinding disc

12.Widened discharge port, more smoother, and the baffle prevents the feed from falling.

| Model No. | Weight(kg) | Power(kw) | Capacity(kg/h) | Dimension(cm) |

| AKK-125 | 35 | 3 | 80-100 | 110*35*70 |

| AKK-210 | 110 | 7.5 | 200-300 | 115*45*95 |

| AKK-300 | 400 | 22 | 500-700 | 145*62*120 |

| AKK-400 | 750 | 30 | 900-1200 | 160*67*145 |

| AKK-500 | 800 | 42 | 1200-1600 | 175*82*160 |

Tips:As the freight changes frequently, please confirm the latest freight with us before ordering.

| Model/Specification | AKK-125 | AKK-300 | AKK-400 | |

| Package&Delivery | Package | 1set/ctn/plastic wrap/wooden box | ||

| Package Size | 110*35*70CM | 145*62*120CM | 160*67*145CM | |

| 40' container | 68 SETS | |||

| Delivery Time | Within 15 days after order confirmation | |||

| Payment Terms | L/C, T/T, Western Union, Paypal, Trade Assurance payments | |||

Похожие товары

Новый продукт, 2024, поставка на птицефабрику, горячая распродажа, машина для измельчения корма и измельчителя, комбинированная машина

Машина для измельчения соломы и корма для животных, комбинированная машина для измельчения соломы и измельчителя

Высокопроизводительная двухшнековый сухой корм для собак экструдер для кормов для домашних животных линия по переработке кормов

Многофункциональный смеситель для комбикорма для животных

Многофункциональная машинка для резки соломы

Лидер продаж, измельчитель корма с электродвигателем, поставляемый на птицефабрику и мясорубку, комбинированная машина

Низкая цена, 0,5-1,5 т/ч, оборудование для производства кормов для кур и птиц, корм для овец, корм, мельница

Новые поступления

Новинки товаров от производителей по оптовым ценам