Индукционная печь для плавки чугуна 300 кг стальная литая медь огнеупорная тигельная 500

- Категория: >>>

- Поставщик: PT GENERAL PURPOSE EQUIPMENT INDONESIA

Сохранить в закладки 1601268677377:

Описание и отзывы

Характеристики

Induction furnace for melting iron making machine 300 kg induction steel cast copper refractory liner crucible oven 500KG pot

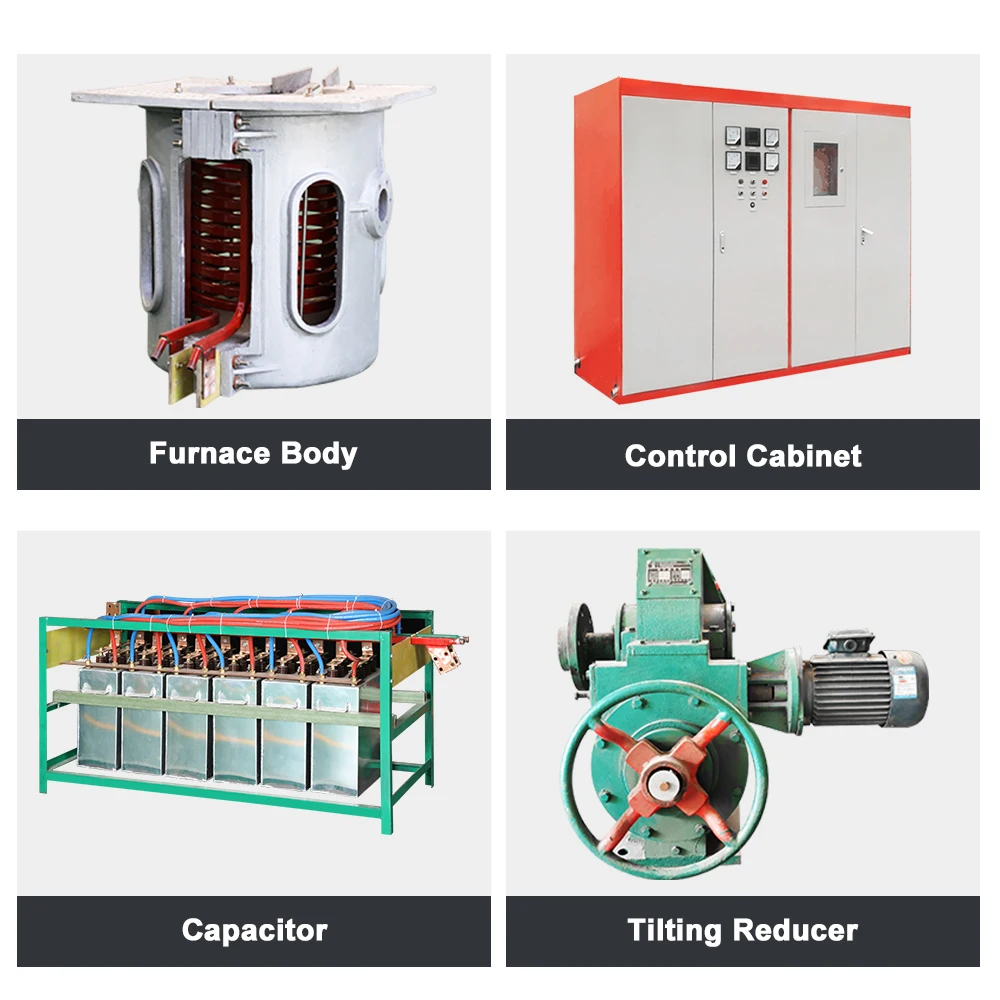

Overview of Steel Iron Melting Furnace

A Aluminum Shell Melting Furnace is a type of industrial induction furnace primarily used in metallurgy and foundry industries to melt metals, particularly steel and iron.

Applications of induction melting furnaces extend beyond steel production, including the melting of other ferrous and non-ferrous metals, making them an integral part of metallurgical and manufacturing industries.

Applications of induction melting furnaces extend beyond steel production, including the melting of other ferrous and non-ferrous metals, making them an integral part of metallurgical and manufacturing industries.

Quintuple Leakage Furnace Protection

Injection type, differential, secondary electrode, optical-fber detection, and cooling system linkage protection.

Coil Induction HeatingTechnology

The optimal number of turns, turn spacing, coil height and other parameters are calculated through computer simulation software to achieve the highest electromagnetic conversion efficiency.

Patent of Scrap Steel Waste Heat Heating

Scrap steel waste heat heating uses high-temperature waste gas or waste heat generated by the furnace to preheat scrap steel. Which can reduce energy consumption and emissions, and improve the overall efficiency.

Stability

The SCR series connection technology can provide customized solution according to different demand & Applications cenarios. Also it can ensure the equipment to run stably in long term, reducing the demand for maintenance & repairing.

Comprehensive Function

Adopting a self-developed third-generation control system: user-friendly operating interface, real-time data monitoring, and real-time energy consumption statistics.Equipped with automatic oven drying,automatic sintering, and cold furnace startup functions.

Intelligence

Integrated in the 5G IOT the system can be monitored & diagnosed online. Even if the engineer is not on site he can still diagnose the system and give advice for repairing.

Advantages of IGBT Power Supply

By adopting advanced digital control technology, the control accuracy is precise to every kilowatt. The stable rectifer and inverter group ensures istable output of full power of the power supply at all times.

High Power

We adoptmodular and integrated design to solve the problem of no-largepower & poor stability oflGBT power supplies in the industry.Our single lGBT power supply can have 50~12000 kW power.

Easy To Maintain

Each pipe fitting adopts PISCO connection for easy maintenance and inspection. Each water circuit has water temperature protection connected to the control system through an inspection instrument.

Energy Economic

Fast switching frequency, low commutation loss, and stable frequency. Multi pulse rectification, without the need for harmonic filters and DIDT. Full power output at all times, short melting time, and high power factor.

Full Protection

Equipped with a door lock linkage system and capacitive pressure switch, IGBT bridge short circuit switch, etc. There is a fuse in front of the frequency conversion group for easy isolation of faulty frequency conversion groups.

Advantages

1. Good Heat Dissipation Performance

Aluminum has very good thermal conductivity and can effectively dissipate the heat generated by the furnace body. This helps to keep the outer surface temperature of the furnace body low and reduce the impact of thermal radiation on the surrounding environment and operators.

2. Improved Metal Quality

Uniform heating leads to better alloying and reduced impurities.

3. High Quality & Low Price

Aluminum is relatively simple to process and manufacture, and the material cost is relatively low, which makes the aluminum shell steel melting furnace have certain advantages in economy.

4. Flexibility

Capable of melting a wide range of metals and alloys.

5. Scalability

Suitable for various production scales, from small batches to large-scale manufacturing.

Technology Parameter | ||||||||||

Furnace Model | Power | Voltage | MF Voltage | Weight | Associated Transformer | |||||

0.1T | 100KW | 3X380V | 750V | 0.6T | 125KVA | |||||

0.25T | 250KW | 3X380V | 750V | 0.65T | 315KVA | |||||

0.5T | 400KW | 3X380V | 750V | 0.9T | 500KVA | |||||

0.75T | 650KW | 3X380V | 750V | 1T | 800KVA | |||||

1T | 800KW | 3X660V | 1200V | 1.2T | 1000KVA | |||||

1.5T | 1200KW | 3X660V | 1200V | 1.2T | 1250KVA | |||||

2T | 1500KW | 3X660V | 1700V | 1.6T | 1600KVA | |||||

3T | 2000KW | 3X950V | 1700V | 1.6T | 2500KVA | |||||

Steel Production

Used in the production of various steel grades.

Integral in processes such as casting, alloying, and refining of steel.

Integral in processes such as casting, alloying, and refining of steel.

Foundry Operations

Essential for melting and casting iron and steel components. Supports the production of automotive parts, machinery, and structural components.

Recycling

Effective in melting scrap metal for recycling purposes. Promotes sustainable practices by enabling the reuse of metal materials.

Похожие товары

High Quality 400 Kgs Crucible Furnace New Condition Hydraulic Tilting for Copper Scrap Melting Best Price Manufacturing Plants

1 132 926,90 ₽

Индукции тигли медь плавления

50 КГ Поворотный SGS Сертификат Производитель Продажи Тигель Завода Комплект для Плавления Меди, Латуни, Бронзы (JLZ-45)

Газовая алюминиевая плавка и Холдинг тигельная печь газовая печь

1 488 989,64 ₽ - 2 265 853,80 ₽

Заводская Горячая продажа 100 кг 300 кг 500 кг IGBT низкая мощность 160 кВт плавильная алюминиевая печь с тиглем

863 182,40 ₽

Высокотемпературное изоляционное приспособление для электродуговых печей эпоксидная изоляция металлургические изоляционные компоненты

129,48 ₽ - 215,80 ₽

High quality brass melting furnace crucible furnace machine gas furnace

1 488 989,64 ₽ - 2 265 853,80 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $