Оптовая продажа высококачественный токарный станок с ЧПУ TCK460 полностью автоматический

- Категория: >>>

- Поставщик: Shandong Yijin Cnc Machine Tool Co. Ltd.

Сохранить в закладки 1601268889101:

Описание и отзывы

Характеристики

TCK460 inclined bed CNC lathe

TCK series multi-functional CNC bed, the bed is made of box structure and tough cast iron (HT-300), cast with integral molding casting technology, and processed by high-precision machining center in one clamping. Therefore, it has the characteristics of strong overall rigidity, good accuracy retention of machine tools, and high reliability in use.

The bed adopts a high-rigidity 45° inclined-back integral bed, which is convenient for chip removal. It is equipped with a separate water tank to completely prevent leakage and is easy to maintain.

The bed adopts a high-rigidity 45° inclined-back integral bed, which is convenient for chip removal. It is equipped with a separate water tank to completely prevent leakage and is easy to maintain.

TCK460

TCK series multi-functional CNC bed, the bed is made of box structure and tough cast iron (HT-300), cast with integral molding

casting technology, and processed by high-precision machining center in one clamping. Therefore, it has the characteristics of

strong overall rigidity, good accuracy retention of machine tools, and high reliability in use.The bed adopts a high-rigidity 45°

inclined-back integral bed, which is convenient for chip removal. It is equipped with a

separate water tank to completely prevent leakage and is easy to maintain.

casting technology, and processed by high-precision machining center in one clamping. Therefore, it has the characteristics of

strong overall rigidity, good accuracy retention of machine tools, and high reliability in use.The bed adopts a high-rigidity 45°

inclined-back integral bed, which is convenient for chip removal. It is equipped with a

separate water tank to completely prevent leakage and is easy to maintain.

Machine tool structure

TCK series multi-functional CNC bed, the bed is made of box structure and tough cast iron (HT-300), cast

with integral molding casting technology, and processed by high-precision machining center in one clamping. Therefore, it has the characteristics of strong overall rigidity, good accuracy retention of machine tools, and high reliability in use.The bed adopts a high-rigidity 45° inclined-back integral bed, which is convenient for chip removal. It is equipped with a separate water tank to completely prevent leakage and is easy to maintain.

with integral molding casting technology, and processed by high-precision machining center in one clamping. Therefore, it has the characteristics of strong overall rigidity, good accuracy retention of machine tools, and high reliability in use.The bed adopts a high-rigidity 45° inclined-back integral bed, which is convenient for chip removal. It is equipped with a separate water tank to completely prevent leakage and is easy to maintain.

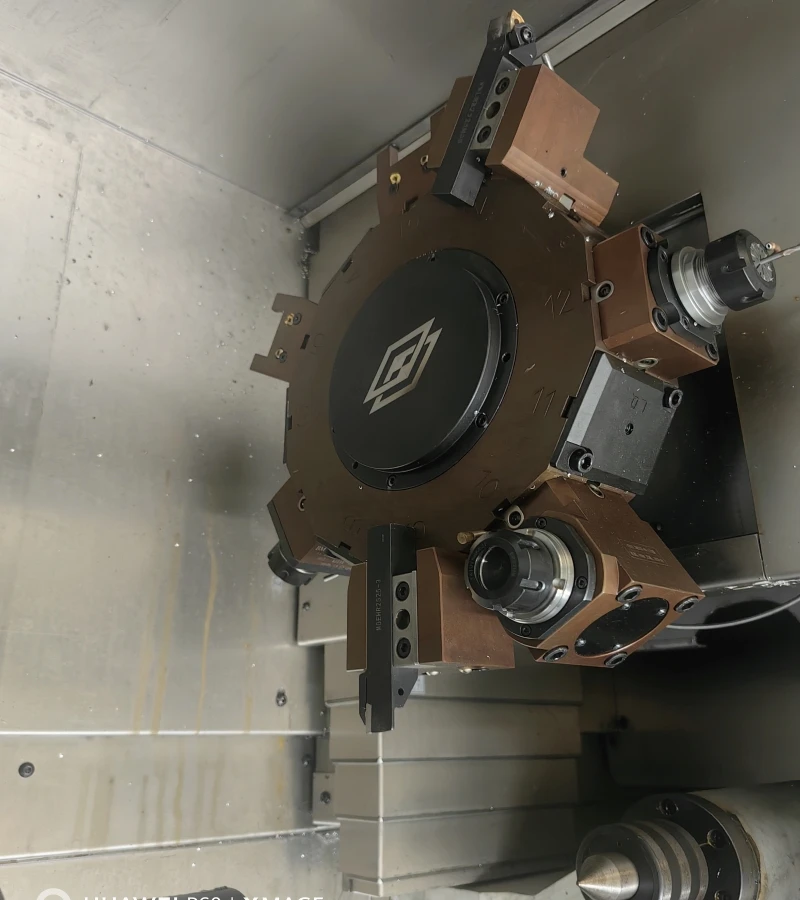

Tool holder

TCK series multifunctional CNC lathe adopts 8-station hydraulic tool holder, and the tool holder can be interchanged at each

position of the tool table. Optional 12-station hydraulic servo turret and live tool turret.

position of the tool table. Optional 12-station hydraulic servo turret and live tool turret.

Spindle

TCK series multifunctional CNC lathe adopts high rigidity spindle unit structure. The closed grease lubrication inside the spindle

can ensure the smooth operation of the spindle at high speed. The spindle motor adopts AC servo motor with stepless speed change,

large torque output and wide range, high torque output at low speed, suitable for heavy cutting. The headstock has no wheel

structure, which greatly reduces noise and vibration. It adopts hollow hydraulic chuck and high-speed oil cylinder, and is

equipped with foot switch, which is convenient for workpiece clamping, safe and reliable.

can ensure the smooth operation of the spindle at high speed. The spindle motor adopts AC servo motor with stepless speed change,

large torque output and wide range, high torque output at low speed, suitable for heavy cutting. The headstock has no wheel

structure, which greatly reduces noise and vibration. It adopts hollow hydraulic chuck and high-speed oil cylinder, and is

equipped with foot switch, which is convenient for workpiece clamping, safe and reliable.

X, Z axis drive

The feed transmission of the X and Z axes adopts (3-level) ball screw, and is pre-compressed and pre-tensioned. The feed of X and

Z axes adopts Taiwan (P grade) four sliders and roller line rails, which have strong bearing capacity and fast moving speed.

Equipped with a screw rail lubrication system, the whole process is forced to lubricate to minimize friction, and it is protected

by a stainless steel telescopic cover. Both X and Z axes use servo motors.

Z axes adopts Taiwan (P grade) four sliders and roller line rails, which have strong bearing capacity and fast moving speed.

Equipped with a screw rail lubrication system, the whole process is forced to lubricate to minimize friction, and it is protected

by a stainless steel telescopic cover. Both X and Z axes use servo motors.

Tailstock

The machine tool adopts a standard hydraulic tailstock, and the movement of the tailstock body is driven by a hydraulic cylinder.

The tailstock guide rail is treated with high-frequency quenching to ensure the best combination of feed accuracy and rigidity of

the machine tool, suitable for heavy cutting. Programmable tailstock is optional.

The tailstock guide rail is treated with high-frequency quenching to ensure the best combination of feed accuracy and rigidity of

the machine tool, suitable for heavy cutting. Programmable tailstock is optional.

Lubrication system

A centralized lubrication system is adopted, and the ball screw and ball rail are fully automatic and forced to lubricate,

ensuring the rapid movement ability and high positioning accuracy of the machine tool.

ensuring the rapid movement ability and high positioning accuracy of the machine tool.

item | value |

Condition | New |

Type | Horizontal |

Year | 2024 |

Max. Length of Workpiece (mm) | 350 |

Max. Spindle Speed (r.p.m) | 3500r.p.m |

Machining Capacity | Medium Duty |

Spindle Bore(mm) | 56 |

Width of bed (mm) | 240mm |

Spindle Motor Power(kW) | 5.5 |

No. of Spindles | Single |

Number of Axes | 3 |

Travel (X Axis)(mm) | 240mm |

Travel (Z Axis)(mm) | 400mm |

Positioning Accuracy (mm) | ±0.01 |

Repeatability (X/Y/Z) (mm) | ±0.003 |

Place of Origin | China |

Shandong | |

Dimension(L*W*H) | 2020*1275*1660 |

Brand Name | YIJINCNC |

Model Number | TCK460 |

Voltage | |

CNC Control System | C |

Tool Post Stations | 8, 6, 4, None |

Weight (KG) | 2600 |

Warranty | 3 Year |

Applicable Industries | Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Construction works , Energy & Mining, Other |

Key Selling Points | Multifunctional |

Showroom Location | None |

Marketing Type | New Product 2024 |

Machinery Test Report | Provided |

Video outgoing-inspection | Provided |

Warranty of core components | 3 Year |

Core Components | Motor, PLC |

Color | Customer Optional |

Max .Swing over bed | 460mm |

Max. swing over carriage | 170mm |

Max. turning length | 350mm |

X/Z axis travel | 240/400mm |

Spindle unit | 170 |

Spindle bore | 56mm |

More products you are interested in

Quality is the lifeblood of the enterprise, grasp the details, open innovation. The company invites to join and agent, willing to

work with our customers and strategic partners to create a better future together.

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services

will be provided.

Похожие товары

TCK500 Токарный Станок С ЧПУ с Наклонной Станиной с мотором и гидравлический координатно-револьверный

FANUC системы токарный станок с ЧПУ IHT516 наклонная кровать токарный станок с ЧПУ

LC-25Y мини-токарный станок с ЧПУ с осью Y, автоматический Высокоточный токарный станок с металлическим наклонным слоем, токарный станок с ЧПУ

DONGS- TCK1000, Китай, сверхмощный токарный станок с ЧПУ, наклонная кровать, токарный станок с ЧПУ, центр токарного станка

7 876 539,40 ₽ - 8 092 335,00 ₽

6150 токарный станок с ЧПУ

830 813,06 ₽

токарный станок с чпу sp2126 с косыми кровать

Высококачественный токарный станок с ЧПУ

2 589 547,20 ₽ - 2 697 445,00 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Оригинальные oem-носки простые грелки для ног женские вязаные

5,25-6,25 $

Мужские Нескользящие Утепленные ботинки для

19,80-25,50 $

Автоматические компоненты 16B универсальный шаровой упаковочный конвейер модульный китайский поставщик система передачи

1-1,50 $

Хромированная стальная мебель ножки стола металлическая основа журнального столика

Лучшее качество 2000 Вт портативная электростанция солнечный генератор сертифицированный LiFePO4 чистый синусоидальный инвертор фонарик

Changan 4*2 Электрический небольшой моющий грузовик высокого давления для продажи от производителя

3 890-4 890 $

45-тонный экологически чистый контейнерный штабелер SANY SRSC45C30 ISO сертифицированный кран

35 700-53 550 $

CL0126 304 U-образная металлическая плитка внутренняя отделка для плитки из нержавеющей стали Декоративная полоса

0,68-2,88 $