FDLT автоматическое барабанное опрокидывающее устройство Бочкообразная плавильная машина битума

- Категория: >>>

- Поставщик: Dezhou Feiteng Road Construction Equipment Co. Ltd.

Сохранить в закладки 1601268891204:

Описание и отзывы

Характеристики

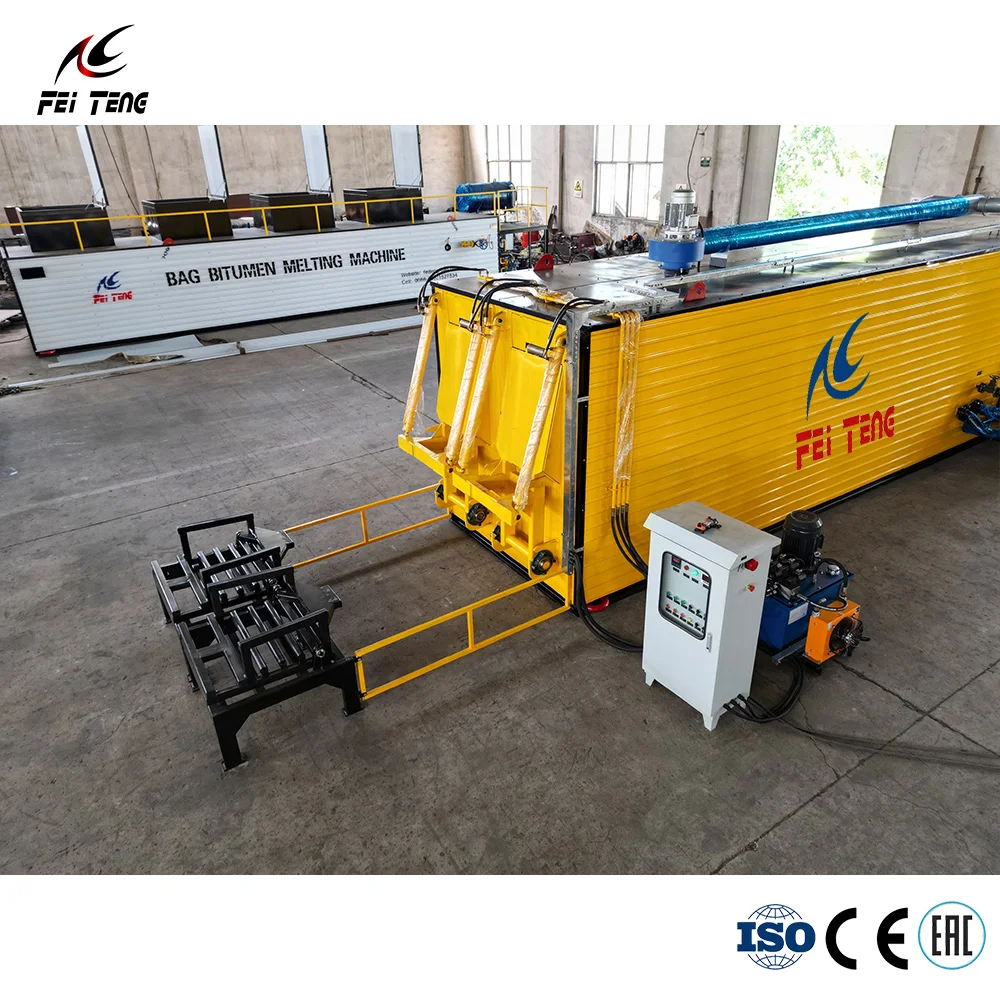

FDLT Automatic Drum Tipping Device Barrel Bitumen Melting Machine

The FDLT series bitumen dumping equipment developed by our company takes thermal oil as heating medium, and the equipment heats

the coil to finish the heating, melting and dumping process. And the equipment guarantees the heating quality and has the features

of high heating efficiency, high dumping speed, labor intensity reduction and pollution reduction.

The bitumen melting equipment consists of melting tank, thermal oil heating system, hydraulic feeding system, bitumen inner

circulation devices, bitumen pump, hot air circulating system and electric control system.

The melting tank is divided into two chambers. The upper one is bitumen dumping chamber equipped with heating coil, and the

heating coil exchanges the heat with barrel in radiation to melt the bitumen.

The two sliding ways are barrel pushing passage. The lower chamber continues to heat the bitumen to reach the required

temperature(110°C), then the bitumen can be pumped into storage tank after the bitumen reaches the operation temperature and has

no moisture, also with with necessary monitoring instrument and safety control device.

Main features of FDLT bitumen melting machine

* The equipment adopts automatic spring door sealed box structure. The drums can be lifted by the forklift and put on the

flipping frame, then click the corresponding channel button on the remote control under 'remote control mode' to

automatically complete the drum loading process, the operation is simple and labor-saving.

* Dumping efficiency: adopt multi-layer heating to ensure the thermal efficiency, thermal oil two inlets/two outlets, high

energy utilization, and the dumping body is insulated by superior mineral wool material.

* Environmental-friendly: closed structure and no pollution.

* Complete removal: the upper side of dumping device has large heat storage and each barrel is directly heated by the thermal

oil coil. The above mentioned advantages guarantees the bitumen can be removed completely and no waste.

* Strong adaptability: it could be suitable for various drum diameters between 500-580mm.

* Automation: the device can achieve one click drum loading, clicking the corresponding channel button on the remote control

under the remote control mode can automatically complete the drum loading process, greatly reducing labor.

* Easy relocation: modular design, easy to transport and assembly.

Item | Unit | Parameter |

Capacity | t/h | 8-10 |

Melting residual rate | % | ≤0.2% per drum |

Melting speed | Drum/hour | 50-60 |

Heating efficiency | % | ≥90 |

Production type | Continuous production | |

Heating mode | Thermal oil indirect heating | |

Melting tank volume | m³ | 15 |

Bitumen pump model | 3GN80×2-46 | |

Drum size | mm | Φ500-580 |

Sliding way | Line | 2 |

Drum quantity | Drum | Φ500 (32) Φ580 (28) |

Bitumen temperature | °C | 110-140 |

Thermal oil operation temperature | °C | 200-240 |

Total heat exchange surface | m² | 103 |

Thermal oil volume | m³ | 1.15 (≈1035kg) |

A: We are Factory with 15 years of production experience.

Q: What's your advantages?

A: More than 15 years experience, professional design, fast delivery and quick response.

Q: How's about the payment terms?

A: We usually accept T/T, LC. T/T: 30% in advance as down payment, the balance before delivery.

Q: How's about the trade terms?

A: EXW, FOB, CFR and CIF are acceptable.

Q: How about the delivery time?

A: Usually we need about 20 days production time after down pay.

Q: How about after-sale service?

A: Our products' quality warranty is one year after delivery, we can provide online support, also can send out our engineers to your place if you want.

Q: What should I do for the quality problems?

A: If you meet quality problems please send to me the products photo first ,our after service department will deal with for you.

Похожие товары

Красный одноугловой Улучшенный прибор для измерения дорожной разметки с обратным отражением

Howo 8 CBM распределитель асфальта грузовик дорожное оборудование битум опрыскиватель для продажи

18 5 т 19 моторный грейдер SG24 SG24-C5 3965 мм режущая кромка лезвия

Интеллектуальный распределитель битума распылитель грузовик

Распродажа хорошее качество уплотнитель для трамбовки 80 кг RM80 машина умножения Заводская поставка

Квадратная форма термического нагрева масла автоматический резервуар для хранения асфальта битумный дорожного строительства

Траншейный экскаватор

Новые поступления

Новинки товаров от производителей по оптовым ценам