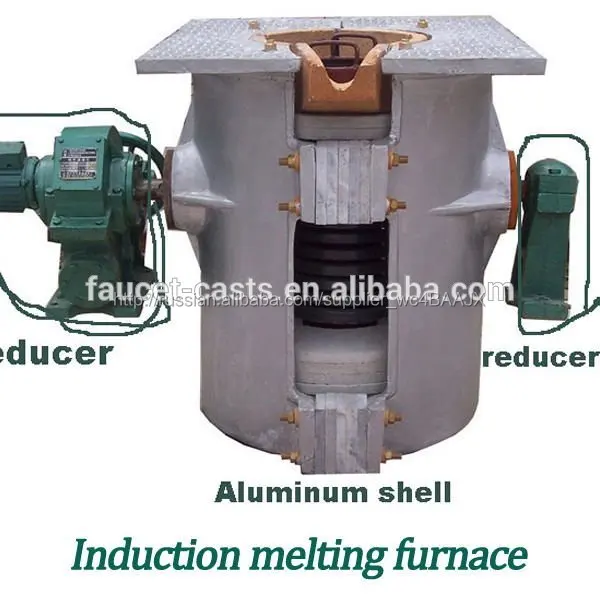

Professional Factory Made Line Frequency Cored Hydraulic Tilting Upward Casting 8000T Induction Copper Melting Furnace

- Категория: >>>

- Поставщик: Wuxi Wondery Industry Equipment Co. Ltd.

Сохранить в закладки 1601268894968:

Описание и отзывы

Характеристики

Product Introduction

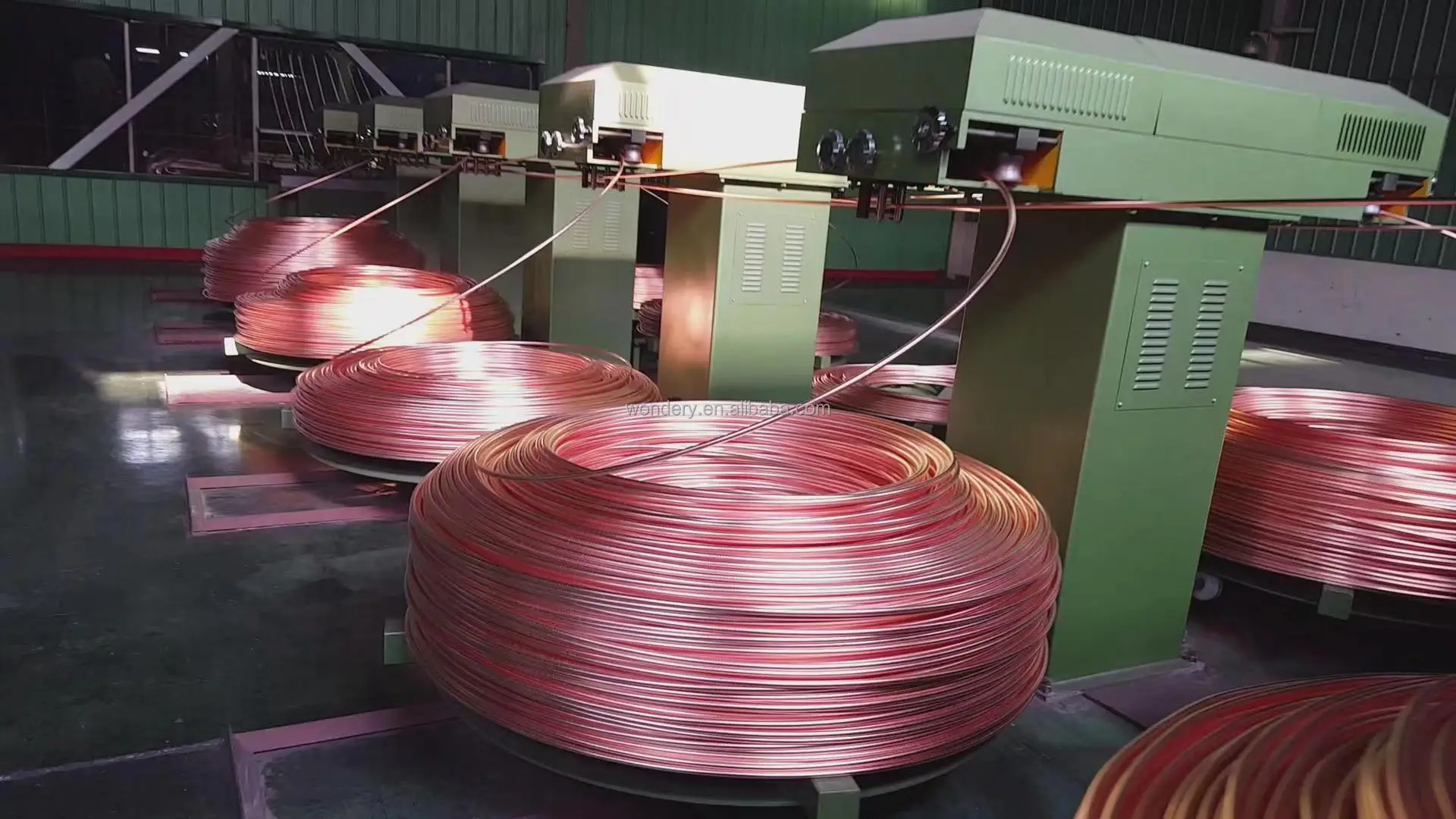

The upward continuous casting oxygen free copper rod production line is specifically used to produce high conductivity oxygen free copper rods. When changing the clamping wheel of the crystallizer machine, other specifications of copper rods and copper pipes with other cross-sectional products can also be produced. The specifications of the casting process are between 8mm and 20mm, with a daily production capacity of around 26T. A 500KG triple continuous casting unit is used, with an annual output of 8000 tons. The unit is driven by imported servo motors and is equipped with advanced pitch control systems in China. Users can directly meet the special requirements of the casting process by inputting the pitch length.

Tilt induction furnace Tilt induction furnace Tilt induction furnace Tilt induction furnace

500KG Triple connected furnace

Rated total power of melting furnace | 300KW | ||

Rated power of holding furnace | 120KW | ||

continuous casting heads | 16 | ||

Continuous casting rod diameter | Ф8mm | ||

Maximum continuous casting production capacity | 8000T/Y | ||

Upward draft speed | 560-2400mm/min | ||

Working hours | per year 7200 hours | ||

Liquid level tracking accuracy | ±2mm | ||

Specification for coil winding size | Ф700mm x 1600mm x 800mm | ||

Copper melting power consumption rate | <325kwh/ton | ||

Power factor | 0.9-1 | ||

Cooling water pressure | 0.25-0.3mpa | ||

No. | Item | Parameter | ||

1 | density | 8.9 kg/dm3 | ||

2 | tensile strength | >170 N/mm2 | ||

3. | elongation | >35% | ||

4 | conductivity | Soft state≥100% IACS(φ2m2n) | ||

5 | oxygen content | ≤10 ppm | ||

Похожие товары

Наклона индукционного типа небольшой mеталлоплавильная печь

1000 кг автоматический редуктор наклонный чугунный лом металлоиндукци

1 тонна меди для применения в промышленной печи, легко очищается, на масляной топливе, гидравлический, опрокидной металл, по разумной цене, металлический сердечник двигателя

Печи сопротивления тип и плавильная печь использование наклона печи ифань печи

Cf-12t наклона 12kg емкость асинхронных золота печи плавления

Типичные наклон индукционной цветных металлов плавильной печи для продажи

Механические наклона стали лом Coreless индукционные плавильные печи

Новые поступления

Новинки товаров от производителей по оптовым ценам