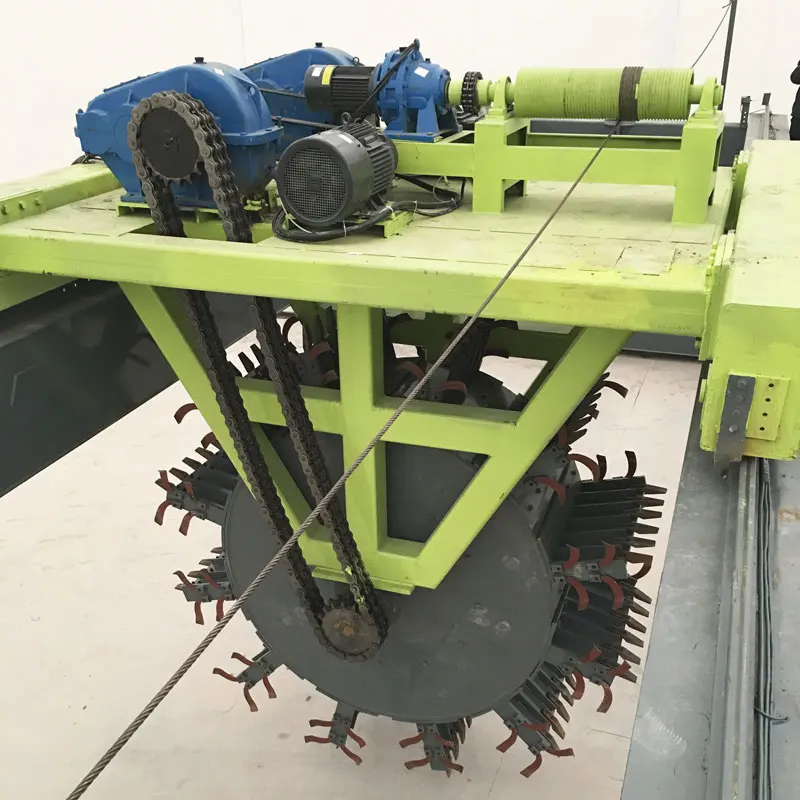

Автоматическая машина для компоста навоза органическое удобрение ферментационный колесный токарный станок ферма новая активная моторная сердцевина

- Категория: >>>

- Поставщик: Henan Tongda Heavy Industry Science And Technology Co. Ltd.

Сохранить в закладки 1601268906967:

Описание и отзывы

Характеристики

Model | Main Motor Power(kW) | Moving Motor Power(kW) | Trolley Motor Power(kW) | Turning Width(mm) | Turning Depth(mm) |

TDLPFD-20000 | 45 | 5.5*2 | 2.2*4 | 20 | 1.5-2 |

TDLPFD-20000(NEW) | 45 | 5.5*2 | 2.2*4 | 22 | 1.5-2 |

Product introduction

1. The type compost turner is our company's patent product.

2. It is suitable for fermentation with large spans and high depths of livestock manure, sludge, garbage, filter mud from sugar mills, worse slag cake and straw sawdust, and other organic waste.

3. The machine is also widely used in organic fertilizer plants, compound fertilizer plants, sludge and garbage plants, horticultural farms, and bisporus plants for fermentation and water removal.

Performance characteristics

1. Large turning depth: The depth can be 1.5-3 meters.

2. Large turning span: The largest width can be 30 meters.

3. Low energy consumption: Adopt a unique energy-efficient transmission mechanism, and the energy consumption of the same operating volume is 70% lower than that of the traditional turning equipment.

4. Flexible turning: The turning speed is symmetry, and under the displacement of the governor shift trolley, there is no dead angle.

5. High automation: It is equipped with a fully automated electrical control system when the turner is working without the need for an operator.

Working principle

1. The advanced fermentation process adopts microbial aerobic fermentation. The compost turner produced by our factory is designed according to the principle of aerobic fermentation technology so that the fermentation bacteria have a space to fully exert their functions. If the pile is too high or uses bucket machinery, fermentation, etc., an anaerobic state will be formed in the pile, so that the function of the fermenting bacteria cannot be fully exerted, which affects the quality of the fertilizer and its production cycle.

2. The compost turner is more suitable for the action mechanism and process requirements of microbial fermentation materials, and can effectively mix viscous materials with microbial preparations and straw powder. Created a better aerobic environment for material fermentation. Under the loose material properties, the material deodorizes in 7-12 hours, heats up in one day, starts to dry in three days, and becomes fat in five to seven days. It is not only faster than deep tank fermentation but also effectively prevents hydrogen sulfide during fermentation. The production of harmful and malodorous gases such as amine gas and antimony, which meet environmental protection requirements, can produce good bio-organic fertilizer.

Notice:

We also have other fertilizer processing equipment, like compost turners, crushing equipment, mixing equipment, drying and cooling machines, and auxiliary equipment.

The different BB fertilizers, organic fertilizers, compound fertilizer production lines, and water-soluble fertilizer fermentation equipment can also be provided.

Pre-sale Service:

1. Offering comprehensive technical and business consultation services;

2. Proposing the most suitable scheme and equipment for our clients;

3. Designing and fabricating targeted products according to the special requirements of clients;

4. Training periodically highly qualified service technicians.

5. Free CAD design: if you can provide the material, your aim capacity, and your factory information, we can make a free CAD design for you.

After-sales Service:

1. Highly inspecting equipment in every working procedure, quality comes first;

2.Fast & Safe Delivery;

3. Assisting our clients with the foundation construction of equipment;

4. Dispatching engineers to install and debug equipment;

5. Training the first-line operators on site;

6. Regularly visit clients to solve production problems Providing life-long maintenance service

7. Providing technical exchange.

Notice:

1. Big machines packed in nude or shipping in containers.

2. Spare parts packed in wooden case.

3. We will pack as requested if you have any special requirements.

1. Are you a manufacturer or trade company?

We are a professional manufacturer of fertilizer processing equipment and related machines (fermentation machines, granulators, crushers, mixers, packaging machines, feeders, conveyor belts), etc. We have more than 30 years of production experience.

2. What are your main products?

Our main products include complete equipment of fertilizer production line. There are many types of granulators and some auxiliary equipment (drying and cooling machines, screening machines, coating machines, packaging machines, and so on).

3. How to choose the most suitable machine?

Just tell us your raw materials, capacity (tons/hour), and the size of the final particle product, and we will choose the machine for you according to your specific situation.

4. Do you provide the installation service after ordering your machines?

As for the single machine, we provide the user's instruction and operation video. As for the production line, we provide the professional construction drawing and arrange for the engineer to guide the user install the machines. Help the user train the skilled workers.

5. What should to do if I encounter some trouble while using it?

The English manual book and video will be provided to show how to resolve the problems, if necessary, we will dispatch our engineer to your factory.

Похожие товары

Cow Dung Compost Chicken Manure Composting Machines Pellet Fertilizer Making Machine High Quality Fertilizer Granulator Machine

Коровий навоз органическое удобрение гранулированная ферментация машина

Производитель, оптовая продажа, мобильный токарный аппарат для компоста, токарь для компоста, куриный навоз, пищевые отходы, измельчитель мусора, токарь для компоста, продажа

Машина для обезвоживания экскрементов

Куриный навоз навоза / коровий навоз навоза производство органическое удобрение машина

Машина для обезвоживания осадка животный барабанный сепаратор навоза

Машина для обезвоживания экскрементов

Новые поступления

Новинки товаров от производителей по оптовым ценам