Высокоточные компоненты машинного оборудования 5 осевая обработка анодированные сервисные алюминиевые фрезерные детали с ЧПУ

- Категория: >>>

- Поставщик: Guangzhou Fengye Metal Manufacturing Co. Ltd.

Сохранить в закладки 1601269000479:

Описание и отзывы

Характеристики

High precision machinery components 5 axis machining anodizing service cnc aluminum milling parts

| Material Available | |

| Aluminum | AL6061, AL6063, AL6082, AL7075, AL5052, A380, etc |

| Stainless Steel | 303, 304, 304L, 316, 316L, 410, 420, 430, etc |

| Steel | Mild Steel, Carbon Steel, 1018, 1035, 1045, 4140, 4340, 8620, XC38, XC48, E52100, Q235, SKD11, 35MF6Pb, 1214, 1215, etc |

| Iron | A36,45#, 1213, etc |

| Brass | HPb63, HPb62, HPb61, HPb59, H59,H68, H80, H90, etc |

| Copper | C11000, C12000, C22000, C26000, C28000, C36000 |

| Titanium Alloy | TC1, TC2, TC3,TC4, etc |

| Plastic | ABS, PC, PP, PE, POM, Delrin, Nylon, Teflon, PEEK, PEI, etc |

| Get A Free Quotation Now>>> Go | |

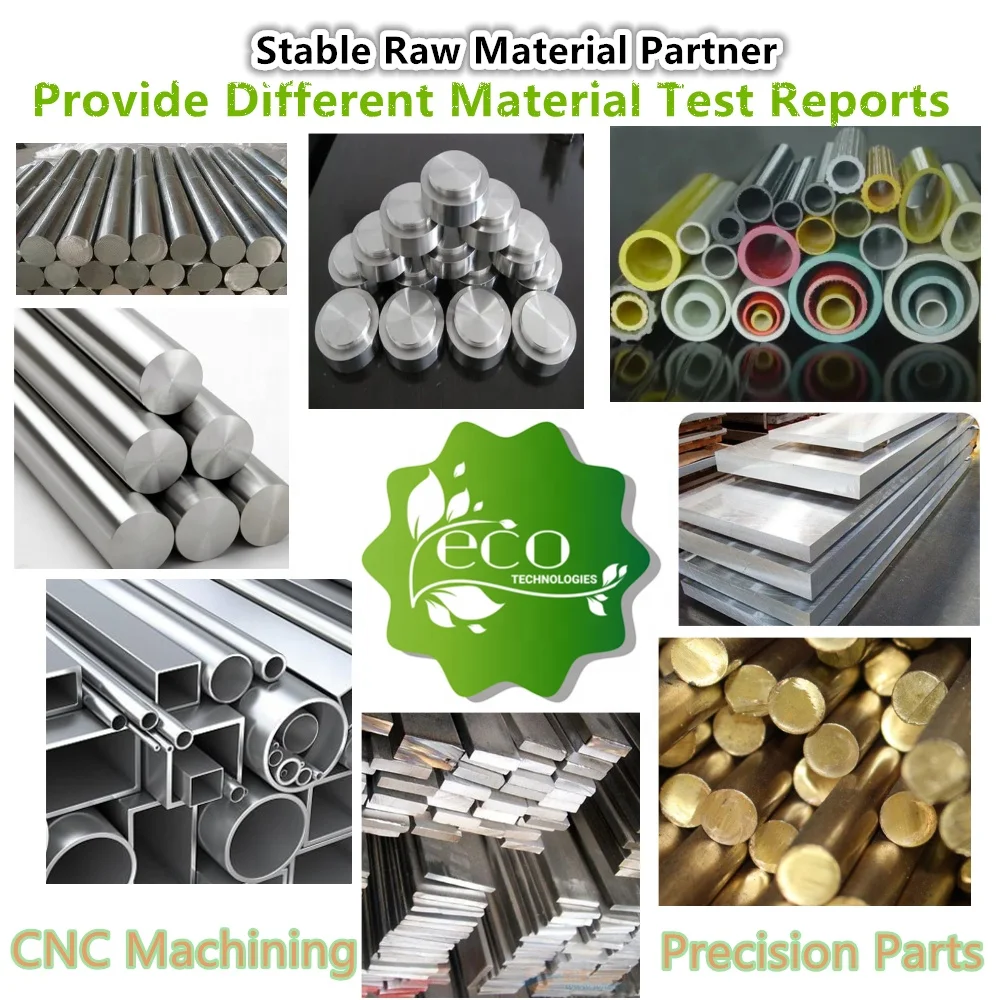

We have an experienced and skilled team that continuously improves production efficiency and processing accuracy by introducing advanced processing equipment and technology, ensuring that every product meets customer expectations and requirements.

We strictly control every step from raw material procurement to production and processing, to product inspection and packaging. We use high-quality raw materials, undergo meticulous processing and strict inspection, and finally deliver products that meet customer requirements to customers through a comprehensive packaging and logistics system. In addition, we have established a comprehensive after-sales service system to provide customers with timely and professional technical support and solutions, truly achieving one-stop procurement and customized processing services.

Over the years, we have established long-term and stable cooperative relationships with enterprises from various industries around the world, providing them with high-quality CNC machining and precision parts processing services. Their satisfaction and trust are important supports for our continuous development and growth.

We welcome customization of various packaging methods to provide you with stable packaging services. We have a strong and comprehensive logistics system that enables customized machined parts to be delivered to customers in a timely and safe manner.

As a professional manufacturer engaged in exporting CNC machining and foreign trade stamping parts processing, we provide customers with high-quality products and services with excellent technical strength, strict quality control system, and reasonable pricing strategy. We always adhere to the principle of customer first, listen carefully to customer needs, and do every detail with care. Choosing us means choosing a trustworthy partner, let's work together to create a better future!

Похожие товары

4140 стальная низкоуглеродистая сталь Aluminum5052 Aluminum2618 алюминиевый сплав топливного бака сварного шва на Заливная Горловина Крышка масляного

Токарный станок с ЧПУ 4WD модифицированные аксессуары латунный блок противовеса амортизатор стабилизатор устойчивости

Пользовательские алюминиевые электронные корпуса для батарей алюминиевый корпус с порошковым покрытием Akzonobel

Запчасти для механических валов другие детали автокомпонентов и аксессуаров удлиненные тонкие расширяющие вала оборудования

Заказной провод EDM изготовленный на заказ латунный металлический CK500L поворотный центр ступицы колеса CNC автозапчасти

Профессиональные высокоточные детали для изготовления металлообрабатывающей обработки из нержавеющей стали с ЧПУ

Пользовательские металлические детали не тратят RFQ просто отправьте нам чертежи предоставьте высококачественный продукт по лучшей цене на нашем собственном заводе

Новые поступления

Новинки товаров от производителей по оптовым ценам