Чудесная печь для отжига газа и азота с электрическим сопротивлением 3 2 м круглых стержневых нагревательных элементов из нержавеющей стали

- Категория: >>>

- Поставщик: Wuxi Wondery Industry Equipment Co. Ltd.

Сохранить в закладки 1601269359464:

Описание и отзывы

Характеристики

Product Application

This equipment is mainly suitable for vacuum annealing heat treatment of workpieces ≤ 2.5m long. During operation, the furnace is vacuumed in a cold state. After heating and heat preservation at the process required temperature, when the temperature drops below 50 °C , the furnace cover is opened and the workpiece is taken out of the furnace.

bogie hearth furnace bogie hearth furnace bogie hearth furnace bogie hearth furnace bogie hearth furnace

Main Technical Specifications | ||

Rated Power | 55KW (1-100% adjustable) | |

Effective loading space of furnace | Ø300×3200mm | |

Power supply voltage | 3P 380V 50HZ | |

Rated temperature | 1200℃ | |

Common working temperature | ≤ 1100 ℃ | |

Instrument temperature control accuracy | ±1.5℃ | |

Furnace temperature uniformity | ±10℃ | |

Empty furnace power loss | ≤10% | |

Heating element | 0Cr25AL5 | |

Furnace travel motor | 0.75 KW reducer | |

Vacuum degree | about -0.1Mpa | |

Vacuum pump | 2X-8 rotary vane pump | |

Atmosphere type | High purity nitrogen | |

Main Features

Furnace Lining

The furnace lining is a composite structure. The main body is constructed with high-quality aluminum silicate refractory fiber folding blocks produced by Shandong Luyang's vacuum spinning method, using standard fixings and scientific and reasonable installation methods.

Heating Element

The heating element is made of iron-chromium alloy (0Cr27AL7Mo2) high temperature resistant alloy strip processed into a corrugated shape and installed on the furnace body. The resistance strip is made of a special mold to ensure that it is not damaged during processing.

Control Cabinet

The temperature control adopts Japan Shimaden temperature controller. By setting its reasonable parameters, the best control of the temperature zone can be achieved. By using its online self-tuning function, the best PID parameters of the furnace can be calculated to achieve a more ideal temperature stability.

No. | ITEM | Q’ty | Remark |

1 | Furnace body | 1 set | Including reducer |

2 | Fixed furnace table | 1 set | |

3 | Heating elements | 1 set | Beijing Shougang |

4 | Stainless steel furnace | 1 set | 310S |

5 | Cooling fan | 1 set | 0.55KW medium pressure blower |

6 | Vacuum pump | 1 set | 2X- 8 |

7 | Temperature control system | 1 set | |

8 | Control cabinet | 1pc | 1800X800X600mm |

9 | Temperature controller | 1pc | |

10 | Power regulator | 1 set | |

11 | Compensation wire | 30m | |

12 | Thermocouple | 2pcs | K-Type |

13 | Supporting electrical components | All | Contactor, air switch, ammeter, voltmeter, thermal relay, switch, etc. |

14 | Technical data | ||

15 | General | 1 copy | |

16 | Electric furnace external wiring diagram | 1 copy | |

17 | Electrical schematic diagram of temperature control system | 1 copy | |

18 | Electric furnace instruction manual | 1 copy |

Похожие товары

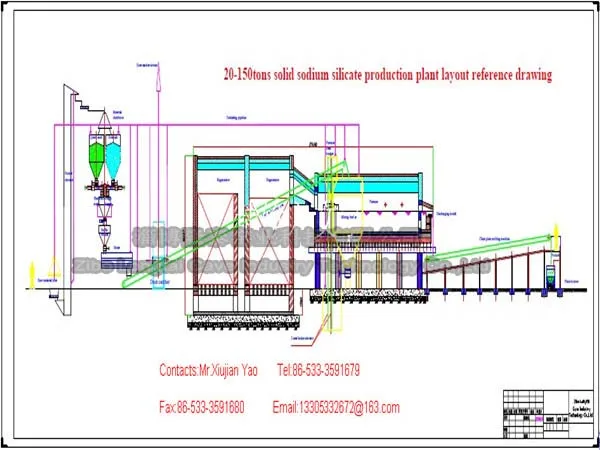

20-22 тонн/день подковы пламени твердых силикатных натрия производственной линии

50000 тонн в год подковы пламени твердых силикатных натрия использовать печь машина

Высокое качество атмосфера печи для плавки золото 1600C

igbt модели 30kw ближний индукционные тепла для пластиковых винт с системой управления plc

поставка завода и низкая цена печи для плавки свинца

медной стали свинец металлолома цветных- черных металлов плавильной печи

Продажа завода Простота В Эксплуатации Алюминиевые Переносные Завод Плавильной Машины с Ведущими Технологии (JLZ-45)

Новые поступления

Новинки товаров от производителей по оптовым ценам