Двухстанционная печь для спекания на основе печи с нижней загрузкой

- Категория: >>>

- Поставщик: Zhengzhou Hengtong Furnace Co. Ltd.

Сохранить в закладки 1601269947819:

Описание и отзывы

Характеристики

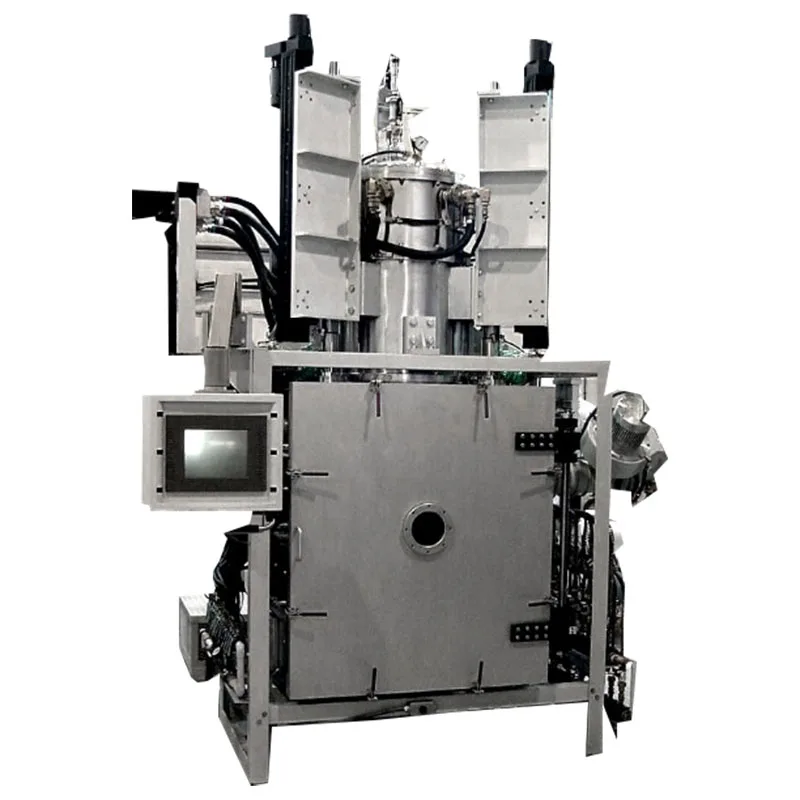

Our two-station sintering furnace is based on our bottom loading sintering furnace, but is capable of simultaneously processing two loads, essentially doubling throughput within the same footprint. Our sintering furnaces are widely found in the electronics industry for sintering or heat treating electronic components at high temperatures. Cycles consist of atmosphere preparation, heating, rapid cooling and controlled oxidation.

The two-station furnace handles two loads simultaneously by heating one load in the hot chamber while cooling the second one in the bottom chamber.

This mechanism is able to switch loads internally without operator assistance. When the heat cycle in the top chamber is complete and a new load is ready for sintering, the top load stack will lower into the bottom chamber, and the new load will be lifted into the top chamber.

The newly-lowered hot load is then cooled in the bottom, undergoes controlled oxidation, and is unloaded when ready. The servo system also rotates the load arms of the bottom chamber to facilitate loading and unloading.

Specifications

Hot zone Size | 12inch diameter*22inch high(305mm*559mm) |

Maximum Temp. | 2100℃ |

Other materials available | Tantalum or tungsten heating zone |

Temperature Gradient | +/-10℃ |

High-capacity diffusion | 10inch or 16inch |

Gas heat exchanger | Rapid load cooling |

Electric load lifes | Precise load movement |

Tantalum or Tungsten | 2100℃ |

High throughput | A high throughput 10inch or 16inch diffusion pumping system handles load out gassing typically seen during product heat-up. |

Warranty | One-year limited standard warranty. |

Our furnace is filled with polyfoam and plastic film inside,while standard foreign trading wooden/paper box out side,the double packages could protect the heat treatment furnace away from the damage during the transport way delivery.

We could send the cargo by express, by air, by sea, or by railway via reliable forwarder.

Zhengzhou HengTong Furnace Co., Ltd, a complete designed and manufactured for furnaces, a global leader in complete thermal processing solutions and technical services essential for the production of advanced materials. From concept to commercialization, from research scale to full production line operations, HT is perpetually on the heating technology. In the past decades, we have pioneered some of the world’s most innovative, customized furnace, kiln and oven systems, with a focus on processing materials at high temperature, atmospheres, vacuum, industry production. HengTong furnace range include, laboratory muffle furnace, vacuum tube furnace, dental zirconia sintering furnace, atmosphere furnace, vacuum furnace, crucible furnace, box chamber furnace, bottom loading furnace, bogie hearth furnace.&The temperature of Hengtong laboratory and industrial furnaces and ovens are ranging from 200 °C to 1800 °C.

1.We are a manufacturer so that we have the punctual delivery time.

2.One sales representative serves you from inquiry to products shipped out.Communicate directly and conveniently.

3.Professional R&D team.

4.Smooth shipping.

5.Rich experience. We do OEM services.

6.Fast reply: Our team will respond your requests within 24-working-hour.

1.How can we guarantee quality?

Final inspection by professional engineers before shipment.

2.How long is the warranty period?

One year limited warranty with lifetime support, excluding heating element and ceramic tube damaged by user.Any damages caused by the use of corrosive and acidic gases, and any damage from wrong operate and use are not under the coverage of One Year Limited Warranty.

3.How to install the furnace?

Our company can train how to install the furnace.

4.How to order your product?

When you are ready to order, please contact us to confirm current pricing, payment arrangements, availability and delivery times for your equipment or accessories. to ensure that your order is properly processed.

5.Do you have customization or OEM service?

We can customize furnaces as product, work piece size, and temperature requirement. Meanwhile, we offer OEM service under the strict industrial standard.

Contact

Tel:+0086-371-63768262

Fax:+0086+371-63768385

All our products will be inspected thoroughly before shipping.Hope you will enjoy this shopping journey and we hope to have a long-time relationship with you. Welcome to visit our factory. Any questions please contact us, we will be of your service.

Похожие товары

Быстрая плавка 1 кг серебряного золота плавления индукционной нагревательной печи для плавки металлов

Электрическая дуговая печь емкостью 5 т для индукционной плавильной печи для металлолома

Индукционная печь для быстрой плавки чугуна, 500 кг

Плавильное оборудование-серия Hj может плавить металлы, такие как золото серебро и медь

Медная удерживающая печь IGBT мощностью 160 кВт для литейного завода, меньшее энергопотребление, постоянная температура

Индукционные печи для плавки металла из нержавеющей стали, металлолом, электрическое железо, плавильная высокотемпературная печь

Быстроплавильная литейная печь, небольшая металлическая плавильная печь

Новые поступления

Новинки товаров от производителей по оптовым ценам