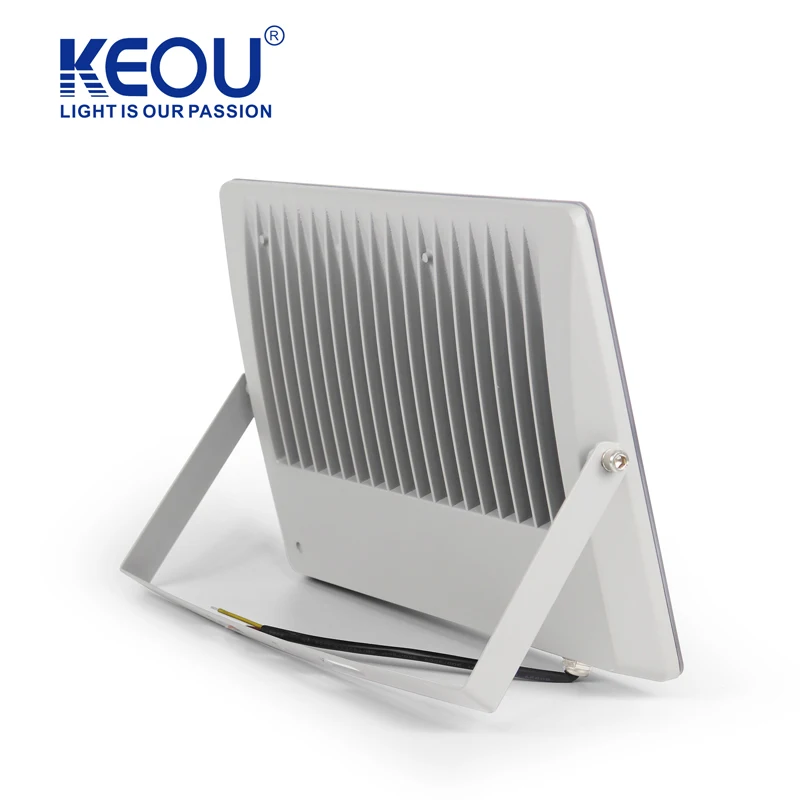

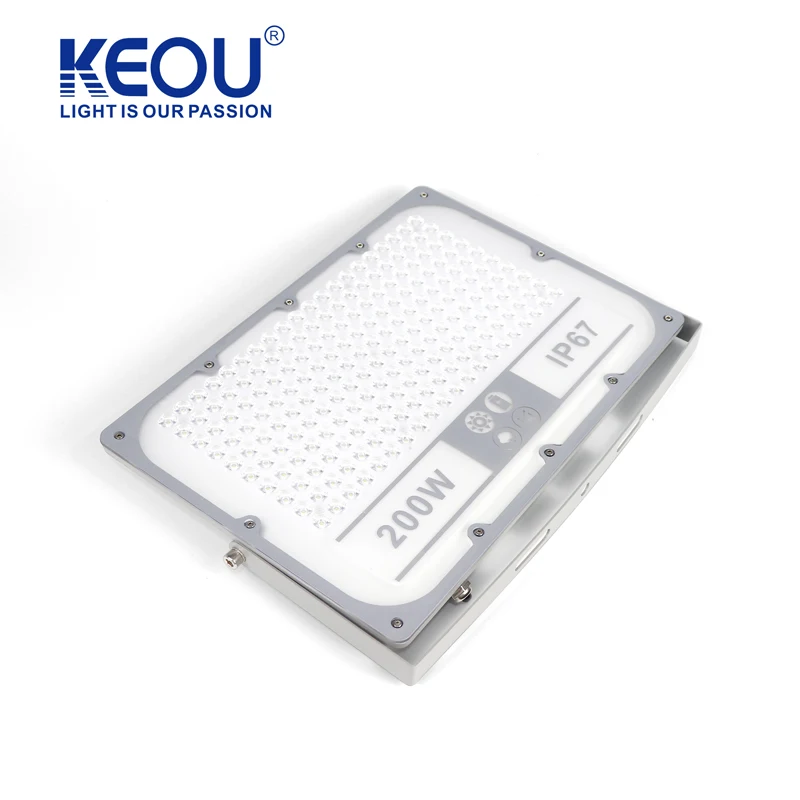

Объектив высокой яркости Ip67 Водонепроницаемый мини 30 Вт 50 100 150 200 алюминиевый светодиодный прожектор

- Категория: >>>

- Поставщик: Guangzhou Keou Lighting Co. Ltd.Guangzhou Ltd.

Сохранить в закладки 1601270146812:

Описание и отзывы

Характеристики

Wholesale instructions

We have 30W, 50W, 100W, 150W, and 200W, with a very wide range of applications. IP67 waterproof, explosion-proof, high safety, high brightness lens projection lamp. We only need a minimum batch of 200 pieces, and the fastest delivery time is 15 days. For 1000 pieces, we can provide OEM ODM customization services with a fastest delivery time of 30 days. Provide a two-year warranty.

| Watt | Model | Lamp size | Beam Angle | Material |

| 30W | KEOU-FL9-30W | 210x135x33 | 120° | Auminum |

| 50W | KEOU-FL9-50W | 245x158x33 | 120° | Auminum |

| 100W | KEOU-FL9-100W | 290x190x33 | 120° | Auminum |

| 150W | KEOU-FL9-150W | 340x230x33 | 120° | Auminum |

| 200W | KEOU-FL9-200W | 390x260x33 | 120° | Auminum |

Give Off Even Light, Long Lifespan

2,Outdoor plazas and parking lots: Lens-type floodlights are widely used in these large-area venues because they can cover a large range of lighting areas, while reducing light pollution and improving lighting efficiency by controlling the beam angle.

3,Building facade and sign lighting: In the lighting projects of building facades, billboards and signs, lens-type floodlights can accurately illuminate specific areas, highlight the details of buildings or signs, and increase visual effects.

4,Industrial and warehousing areas: In areas such as factories, warehouses and docks, lens-type floodlights can effectively focus light, provide workers with a good working environment, and ensure safe production, especially for scenes that require long-term lighting.

5,Airports and ports: Since areas such as airport runways and port docks require high-brightness and wide-range lighting, the precise lighting characteristics of lens-type floodlights are very suitable for use in these large outdoor venues to ensure the safety of night operations.

6,Road and bridge lighting: In areas such as highways, urban roads, bridges, etc. that require long-distance and wide-angle lighting, lens-type floodlights can effectively reduce light scattering, provide uniform road lighting, enhance the driver's line of sight, and improve safety.

7,Stage and performance venues: Stage lighting needs to focus on specific areas or characters. Lens-type floodlights can achieve focus and soft transition through their controllable beam angles to enhance stage effects.

8,Tunnel lighting: The application of lens-type floodlights in tunnels can provide strong and uniform lighting, reduce shadow areas during driving, improve safety, and effectively reduce energy consumption.

How to choose my brand packaging?

|  |  |

| Neutral packaging | Customized packaging | KEOU Packaging |

| Customized content: User instructions, installation instructions, and brand instructions can all be customized. Customized packaging content: Neutral packaging, Brand packaging,Customized packaging Customized minimum order quantity: The minimum order quantity for most products is 1000 pieces per watt. The minimum order quantity for customized products with lower value is 3000 pieces per watt | ||

|  |  |  |

Our company not only provides wholesale services for whole pieces, but also wholesale services for parts. For customers who want to create their own factories or workshops, we provide wholesale components so that they can assemble products locally, saving costs and transportation fees. With rich experience, we provide customers with a full set of equipment, raw materials and other support to help them successfully build their own lighting processing plants. | |||

Why choose Keou as your own processing factory?

Click on the image to watch our factory video

1. Good reputation

The five-star product evaluation has received such a fair evaluation. We have made a lot of preparations and set ourselves the requirements of the industry's top level at every step. We also rely on our comprehensive after-sales service support system.In addition to product supply, we provide dealers with a full range of after-sales service support, including product warranty, technical support, product training and maintenance services. Perfect after-sales service can improve customer satisfaction, reduce dealers' after-sales costs, and at the same time enhance dealers' dependence on suppliers and establish a more stable cooperative relationship.

2. Production capacity and high quality control

The advanced equipment we use includes SMT machines, solder paste machines, laser marking machines, laminators, reflow machines, multi-channel temperature testers, high-voltage testers and high-temperature testers. Each department has a clear division of labor and mutual supervision. Raw material processing workshop, SMT workshop, aging test workshop with four aging lines, 10 production lines. And high-end laboratories equipped with integrating spheres, spectrometers, constant temperature aging furnaces, high-voltage testers, high and low temperature boxes, intelligent power testers and other advanced equipment. We have eight quality control departments and strictly control in accordance with the ISO9001 quality control system.

1. Incoming Inspection

Steps: Inspect the raw materials and parts arriving at the factory to ensure that they meet the company's quality standards and requirements.

Result: Qualified materials can enter the next step; if unqualified, the materials will be returned or accepted on deviation.

2. Input Process Quality Control (IPQC - Input Process Quality Control)

Steps: During the production preparation process, quality control is performed on the materials to ensure that the materials remain qualified before production.

Result: If qualified, the materials enter the production link; if unqualified, further processing or rework is required.

3. Approval of First Finished Product

Steps: After the first batch of products are produced, strict quality inspection is carried out to ensure that the products meet the design requirements and quality standards.

Result: If the first product is qualified, mass production will begin; if unqualified, the design or process needs to be improved and re-inspected.

4. Final Quality Control (FQC - Final Quality Control)

Steps: After mass production, the product is subjected to final quality inspection to ensure that the various indicators of the finished product meet the requirements.

Result: If the product is qualified, it will enter the next stage; if it is unqualified, the QA department will take the lead in problem improvement.

5. Mass Production

Steps: Products that pass the final inspection enter the mass production stage while maintaining continuous monitoring of product quality.

6. Pre-shipment quality inspection

Steps: After the product is packaged, a final quality inspection is carried out to ensure that the products in each package meet the shipping standards.

Result: Qualified products will be sent to customers; unqualified products need to be reworked or re-inspected.

Continuous research on the lighting industry. This is our unchanging passion and pursuit.

3. Professional

Scan the QR code to visit our office and factory

Our factory is located on the 6th floor of Building D, No. 1 Taohong West Street, Junhe Street, Baiyun District, Guangzhou.

4. R&D capability and business capability

Product development department, provide you with free samples. We have provided a series of lighting solutions for more than 2,000 major customers. Professional testing equipment provides you with different test reports. Business territory expands to all parts of the world.

Click on the image to watch our R&D team video

5. Service and Efficiency

30 professional business consultants are online 24 hours a day to answer your questions. Track order details all the time. Contact us.

Похожие товары

1500 Вт Светодиодный прожектор 262500LM супер яркие наружные охранные огни с более широким углом освещения 5700K Дневной свет белый IP66

Открытый водонепроницаемый ландшафтный светильник 10 Вт COB Светодиодный уличный прожектор ip65 садовый точечный

Уличный водонепроницаемый Ультрафиолетовый черный свет 200 Вт 100 50 УФ 395 нм прожектор AC220V флуоресцентный фиолетовый сценический светильник для бара

Hishine новый дизайн светодиодные спортивные светильники SMD7070 светодиодный чип IP66 осветительные столбы для футбольных стадионов

УФ 395NM прожектор IP65 уличный Ультрафиолетовый черный свет 100 Вт 50 светодиодный Алюминиевый 80 Светодиодный Uvb флуоресцентный

Наружные 200 Вт светодиодные прожекторы 100 150 300 IP66

Алюминиевый светодиодный прожектор 30 Вт 50 100 150 200

Новые поступления

Новинки товаров от производителей по оптовым ценам