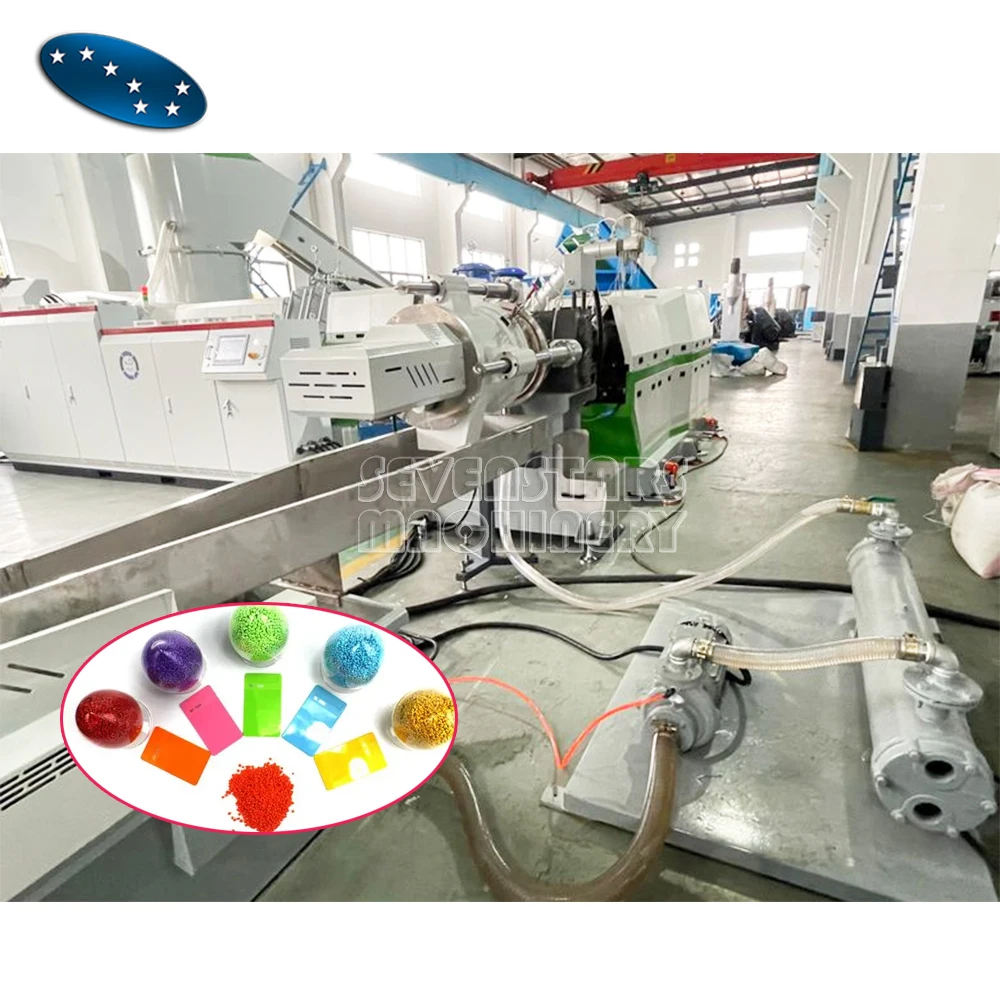

Машина для переработки пластика 300 500 кг/ч

- Категория: >>>

- Поставщик: Zhangjiagang Sevenstars Machinery Co. Ltd.

Сохранить в закладки 1601270193853:

Описание и отзывы

Характеристики

Product Description

Advantages of this plastic pelletizing machine :

PE/PP recycling granulating machine is special equipment for the PE PP film recycling granulating, it equipped with comacting machine which could pre- compact the film into smaller granules, then easily feed into screw barrel of extruder, its efficiency is high and can improve production capacity and save labor cost.

It has two vacuum exhuasting mouth on extruder barrel which can fully vent the moisture in the material and hence the final granule quality will be very perfect.

At the end of screw barrel, it equipped with double post fast speed hydraulic non -stop screen changer which can effetively filt out the dirty in the plastic melt.

The pelletizing adopts water flush pelletizing which is easier to operate, and the shape and appearance of granule is good.

PE/PP recycling granulating machine is special equipment for the PE PP film recycling granulating, it equipped with comacting machine which could pre- compact the film into smaller granules, then easily feed into screw barrel of extruder, its efficiency is high and can improve production capacity and save labor cost.

It has two vacuum exhuasting mouth on extruder barrel which can fully vent the moisture in the material and hence the final granule quality will be very perfect.

At the end of screw barrel, it equipped with double post fast speed hydraulic non -stop screen changer which can effetively filt out the dirty in the plastic melt.

The pelletizing adopts water flush pelletizing which is easier to operate, and the shape and appearance of granule is good.

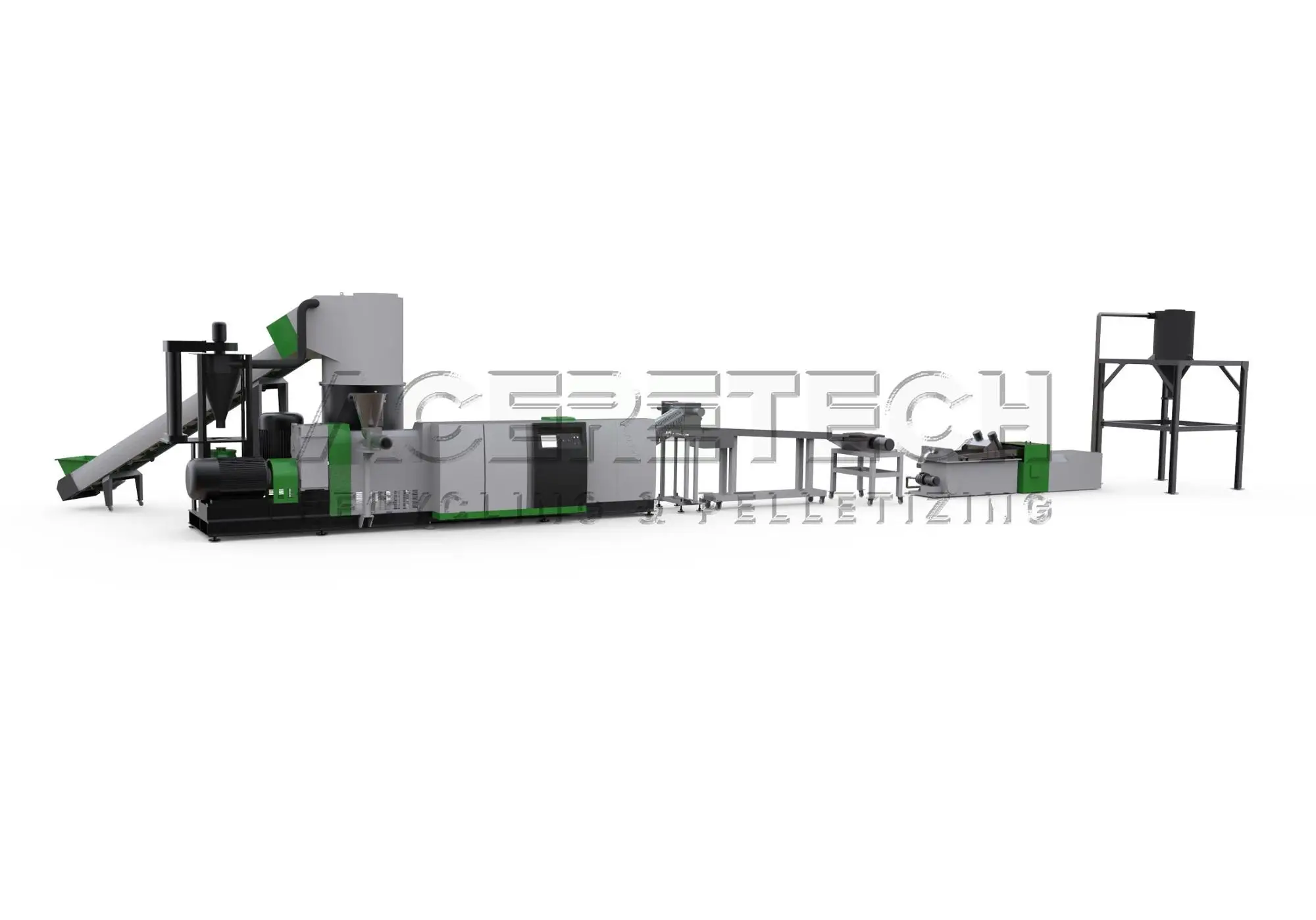

The waste recycling pe plastic granulator machine is designed and manufactured by MOOGE TECH, which is widely used for waste plastic LLDPE film, LDPE film, HDPE film, PE bags, PLA film, etc.

The material go through transmission system, extrusion system, cutting system, cooling system and collect system will turn to be clean perfect pellets for reuse.

You can choose double stage or single stage extruder according to the cleanliness of your material.

We can also design the layout into "L" or "U"according to customers' workshop and special requirement

The material go through transmission system, extrusion system, cutting system, cooling system and collect system will turn to be clean perfect pellets for reuse.

You can choose double stage or single stage extruder according to the cleanliness of your material.

We can also design the layout into "L" or "U"according to customers' workshop and special requirement

1. Extruder

This machine is used to extrude plastic cleaned by high temperature.The extrusion line can be consisted by such accessory machine:

main motor, the gear box, the distribution box, the barrel and screw, the dies, water tank. Main Motor is mainly to supply the power. The Gear box transfers the motor to power.The distribution box enlarges the strength of the power and realizes uniformity.

This machine is used to extrude plastic cleaned by high temperature.The extrusion line can be consisted by such accessory machine:

main motor, the gear box, the distribution box, the barrel and screw, the dies, water tank. Main Motor is mainly to supply the power. The Gear box transfers the motor to power.The distribution box enlarges the strength of the power and realizes uniformity.

2.Mould

We use plug board type to change nets and keep machine working.The mould is made by 40Cr nitridation .The pressure sensor prompts to change the nets.There also can install a hydraulic equipment to change the nets more quickly.

We use plug board type to change nets and keep machine working.The mould is made by 40Cr nitridation .The pressure sensor prompts to change the nets.There also can install a hydraulic equipment to change the nets more quickly.

3.Water cooling tank

The water tank is 4 meters long.Make out article of cooling.

The water tank is 4 meters long.Make out article of cooling.

4. Air dryer

Through the double channels strong wind dryer,force drying and cooling article material reach the fast speed effect of shaping up.

Through the double channels strong wind dryer,force drying and cooling article material reach the fast speed effect of shaping up.

5.Pelletizer machine

It adopts grain design, accuracy is high and can guarantee the rotatory precision and stationery of power, movements of cylinder are controlled by the solenoid valve, the automatic degree is high and the noise is low.

It adopts grain design, accuracy is high and can guarantee the rotatory precision and stationery of power, movements of cylinder are controlled by the solenoid valve, the automatic degree is high and the noise is low.

6.Technical Parameter

Model of PE/PP plastic pelletizing line | SJ85 | SJ100 | SJ130 | SJ160 |

extruder screw diameter | 85 | 100 | 130 | 160 |

main motor of extruder | 55 | 90 | 132 | 160 |

main motor of compacting machine | 37 | 55 | 75 | 90 |

production capacity | 100-150 | 200-300 | 300-400 | 500-600 |

Company Profile

Packing & Delivery

FAQ

Why choose us:

1.low cost :

all the machine ,we make it ourself to reduce the cost of our customer.

2.Genuine product with excellent quality :

we choose our material very strict,

all the material come to our factory must pass the quality test

substandard goods are returned to the supplier.

3. Engerneers available to serve oversea

4.quick delivery:

the company provide just in time delivery with its streamlined supply chain

5.cost saving

we take strong attention to every detail in the manufacturing process,

the quality control in our factory is very strict,

all defective semi-manufactures must be treated again or reject.

all the machine must be checked out ,then deivered to our customer.

all about that pushing up the price,

what we want to do is give our customer a good quality product with stable working and long lived.

1.low cost :

all the machine ,we make it ourself to reduce the cost of our customer.

2.Genuine product with excellent quality :

we choose our material very strict,

all the material come to our factory must pass the quality test

substandard goods are returned to the supplier.

3. Engerneers available to serve oversea

4.quick delivery:

the company provide just in time delivery with its streamlined supply chain

5.cost saving

we take strong attention to every detail in the manufacturing process,

the quality control in our factory is very strict,

all defective semi-manufactures must be treated again or reject.

all the machine must be checked out ,then deivered to our customer.

all about that pushing up the price,

what we want to do is give our customer a good quality product with stable working and long lived.

Похожие товары

двухкаскадный гранулятор переработка ПП АБС флейсков дроблёнок одношнековый экструдер

Горячая распродажа, полипропиленовая полиэтиленовая машина для агломератора полиэтиленовых пленок

3 000,00 $ - 3 600,00 $

Пластиковая соковыжималка, сушилка

1 973 671,20 ₽ - 2 192 968,00 ₽

ACERETECH автоматический контроль температуры и давления передовой гранулятор экструдер для переработки пластика

дробилка для измельчения ПВХ профилей труб листьев

линия грануляции для переработки LLDPE стрейч плёнки

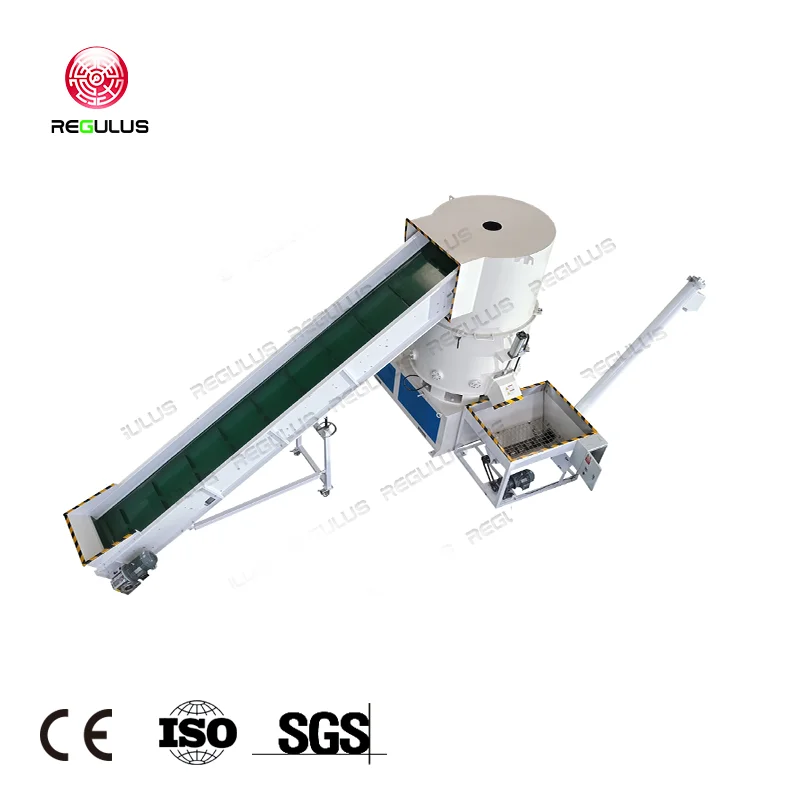

Высокоэффективный бункер PS EPS мягкое устройство для переработки материала агломератор машина с ленточным конвейером

548 242,00 ₽ - 1 096 484,00 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $

Оригинальная популярная клавиатура для рабочего места Genos2 с 76 клавишами

200 $

Умный цифровой электронный ручной инфракрасный лазерный термометр для ветеринарного и медицинского мониторинга человека

5-10 $

Цифровой инфракрасный лазерный термометр для взрослых

5,90-6,70 $

Командная версия 24-скоростной ультралегкий карбоновый шоссейный велосипед Гоночная рама и комплект колес

Четырехцилиндровый двигатель CA6110/125G5 части клапана 1007011-A013-0000 1007016-A013-0000

0,50 $

55203781 46740344 55181201 55266538 зубчатый шкив коленчатого вала для FIAT 500 BRAVA BRAVO DOBLO PANDA PUNT0

3-3,70 $