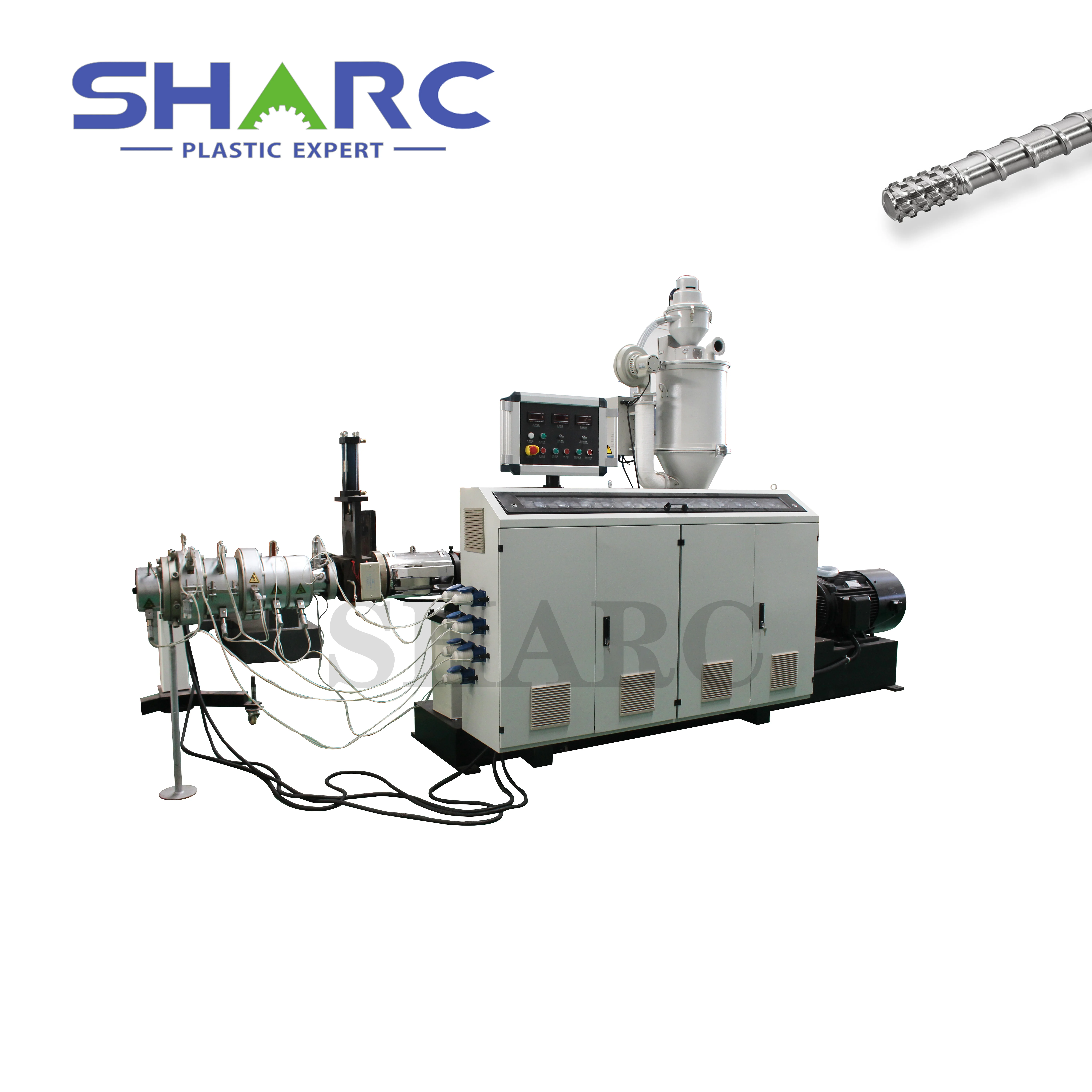

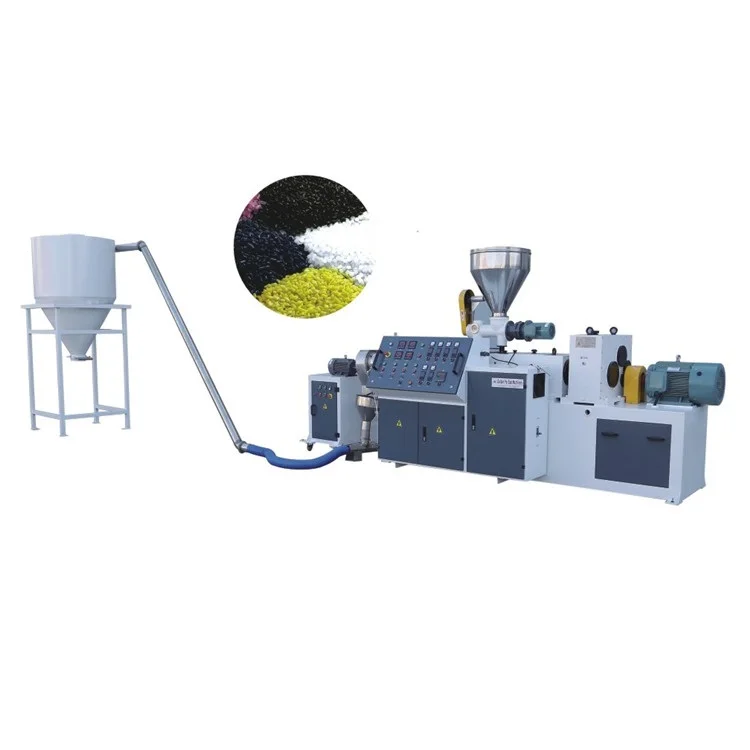

Заводская поставка Одношнековый экструдер высокоэффективный PP PE HDPE пластиковая экструзионная машина для продажи

- Категория: >>>

- Поставщик: Zhangjiagang Sharc Machine Co. Ltd

Сохранить в закладки 1601271036426:

Описание и отзывы

Характеристики

Product Description

About Single screw Extruder machine

The Single Screw Extruder Machine is a commonly used plastic processing equipment, used to extrude molten plastic materials and make plastic products of various shapes according to different needs. The following is an introduction to single-screw plastic extruders:

advantage:

1. High flexibility: The Single Screw Extruder Machine speed and temperature can be adjusted as needed to adapt to different plastic materials and product requirements.

2. High production efficiency:Single Screw Extruder Machine has the ability of high-speed extrusion and can achieve large-volume, high-speed and stable production.

3. Low production cost: Compared with other plastic processing equipment, the equipment and maintenance costs of Single-Screw Plastics Extruder are relatively low.

4. Simple operation: The equipment control system is intelligent and easy to operate and maintain.

advantage:

1. High flexibility: The Single Screw Extruder Machine speed and temperature can be adjusted as needed to adapt to different plastic materials and product requirements.

2. High production efficiency:Single Screw Extruder Machine has the ability of high-speed extrusion and can achieve large-volume, high-speed and stable production.

3. Low production cost: Compared with other plastic processing equipment, the equipment and maintenance costs of Single-Screw Plastics Extruder are relatively low.

4. Simple operation: The equipment control system is intelligent and easy to operate and maintain.

Scope of use:

1. Production of plastic products: including plastic pipes, plates, films, thin-walled products, etc.

2. Preparation of plastic pellets: The raw plastic pellets are melted and then passed through an extruder to make customized plastic pellets.

3. Plastic extrusion molding: used to manufacture plastic extrusion special-shaped materials, such as door and window frame materials, plastic decorative panels, etc.

The working principle of a Single Screw Extruder Machiner is mainly divided into the following steps:

1. Adding materials: Add plastic particles or pellets into the hopper of the extruder, and push the materials into the barrel through the rotating screw.

2. Melting: When the screw rotates, due to the external heating system, the plastic melts under high temperature and high pressure to form molten plastic.

3. Extrusion: The molten plastic is pushed to the outlet of the barrel by the screw, and the molded plastic product is determined by the shape of the die.

4. Cooling: The extruded plastic product is cooled by the cooling device to solidify it into the required shape.

5. Cutting: The cured plastic products are cut through the cutting device to obtain the final plastic products.

1. Production of plastic products: including plastic pipes, plates, films, thin-walled products, etc.

2. Preparation of plastic pellets: The raw plastic pellets are melted and then passed through an extruder to make customized plastic pellets.

3. Plastic extrusion molding: used to manufacture plastic extrusion special-shaped materials, such as door and window frame materials, plastic decorative panels, etc.

The working principle of a Single Screw Extruder Machiner is mainly divided into the following steps:

1. Adding materials: Add plastic particles or pellets into the hopper of the extruder, and push the materials into the barrel through the rotating screw.

2. Melting: When the screw rotates, due to the external heating system, the plastic melts under high temperature and high pressure to form molten plastic.

3. Extrusion: The molten plastic is pushed to the outlet of the barrel by the screw, and the molded plastic product is determined by the shape of the die.

4. Cooling: The extruded plastic product is cooled by the cooling device to solidify it into the required shape.

5. Cutting: The cured plastic products are cut through the cutting device to obtain the final plastic products.

Through these steps, the Single Screw Extruder Machine can convert plastic particles into plastic products of various shapes.

Technical parameter

SJ series single screw extruder

Model | L/D | Capacity(kg/h) | Motor power(KW) |

SJ-25 | 25/1 | 5 | 2.2 |

SJ-30 | 25/1 | 10 | 5.5 |

SJ-45 | 25/1 | 25 | 7.5 |

SJ-55 | 25/1 | 35 | 11 |

SJ-65 | 25-33/1 | 60-250 | 15-90 |

SJ-75 | 25-33/1 | 150-300 | 37-110 |

SJ-90 | 25-33/1 | 180-550 | 37-185 |

SJ-120 | 25-33/1 | 320-800 | 75-280 |

SJ-150 | 25-33/1 | 400-1200 | 90-355 |

Packing & Delivery

Company Profile

ZHANGJIAGANG SHARC MACHINE CO., LTD. is located in Jiangsu Province of china. We have more than 20 years’ experience of manufacturing plastic machinery, including: automatic material mixing&feeding system, plastic profiles extrusion line, plastic sheet production line, plastic pipe production line, plastic panel&board extrusion line, plastic recycling&palletizing machine, surface treatment machines and other auxiliary machines. We always firmly believe: focusing on employees, focusing on products, focusing on clients will be the three key points of enterprise development.

All the products are sold well in every province and city of the whole country and also exported to about thirty countries and areas with strong technical force, advanced equipment, scientific management system and perfect after-sales service.

All the products are sold well in every province and city of the whole country and also exported to about thirty countries and areas with strong technical force, advanced equipment, scientific management system and perfect after-sales service.

Exhibition

FAQ

Похожие товары

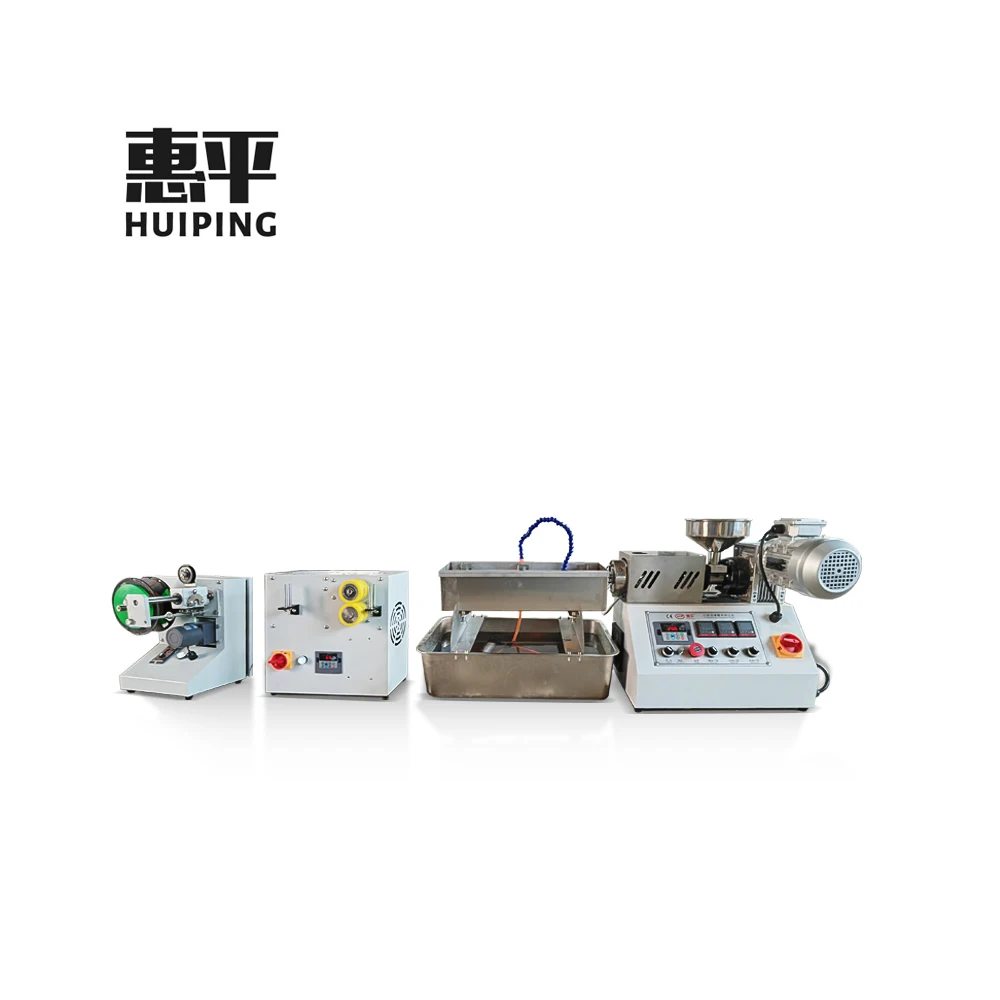

Небольшая пластиковая машина для переработки пластиковых грануляций экструдер

218 786,80 ₽ - 251 604,82 ₽

3D пластиковый экструдер накаливания ABS PLA машина накаливания

306 301,52 ₽ - 328 180,20 ₽

Китай Твин винт Пластик PLA экструдер гранулятор машина

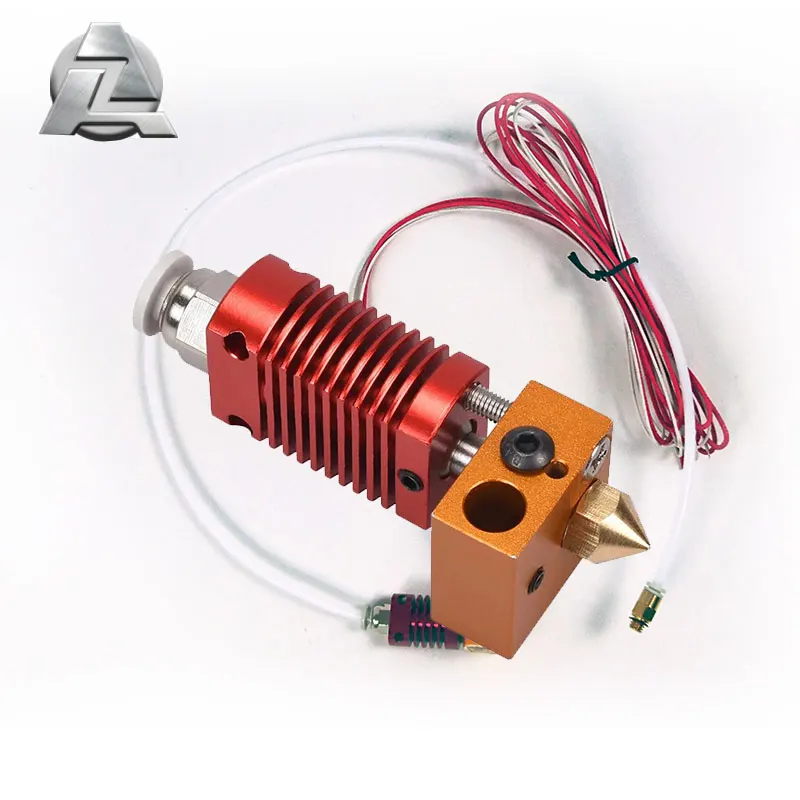

Комплектующие для 3D-принтеров, комплект для горячей печати cr-10v2/cr-10 v3, Набор насадок для экструзионных насадок для cr-10, 3d принтер v2/v3

787,64 ₽

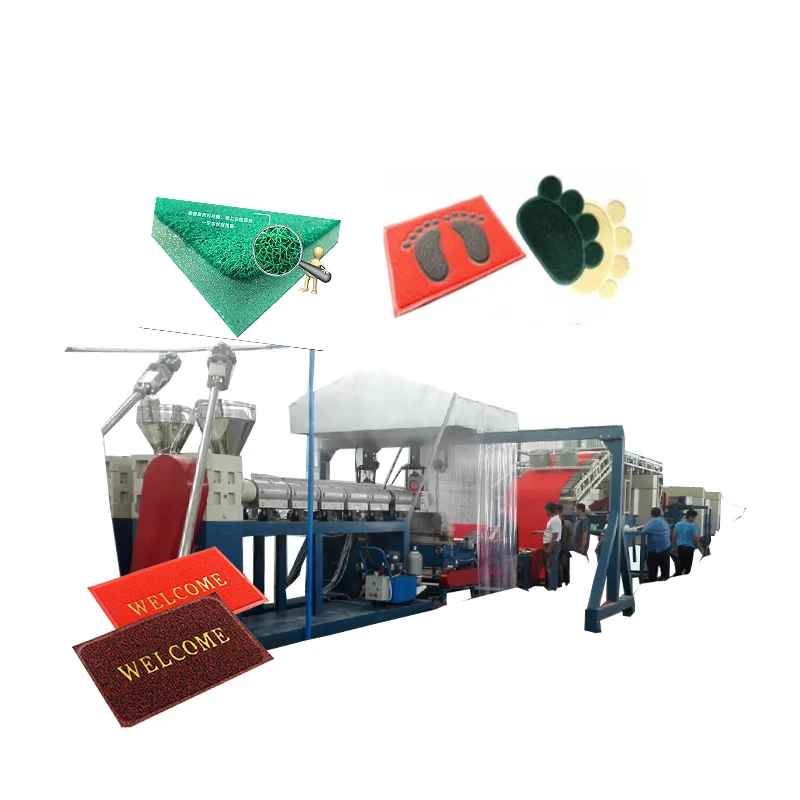

Пвх катушка входной коврик пыленепроницаемый коврик производственная линия

2016 FS уплотнитель pp pe пленка машины окомкования

Высокая скорость двойной винт ПВХ Гранулирующая линия 250 кг/ч машины

Новые поступления

Новинки товаров от производителей по оптовым ценам

Кокосовая стружка мягкая и сладкая на вкус без глютена запеченная Ароматизированная упаковка для приготовления пищи кондитерских

Медицинский одноразовый стерильный катетер

Эффективные акустические панели эффективные звукоизоляционные материалы для качественной

65% полиэстер/35% хлопок саржа TC камуфляжная ткань 220gsm с водонепроницаемым принтом

1,48-1,61 $

Органическое жидкое мыло для мытья рук оптом

0,66-1,46 $

Высокое качество Sunpal 450W-600W 48V фотоэлектрические солнечные панели 500W 500Wp 600W заводская цена с белой задней простыней

0,28-0,32 $

2025 руиба новый продукт зажим для пуповины оптовая продажа медицинский стерильный одноразовый пластиковый

Оптовая продажа индивидуальные синие 3-слойные одноразовые маски для лица хирургические медицинские защитные взрослых

40-41,80 $