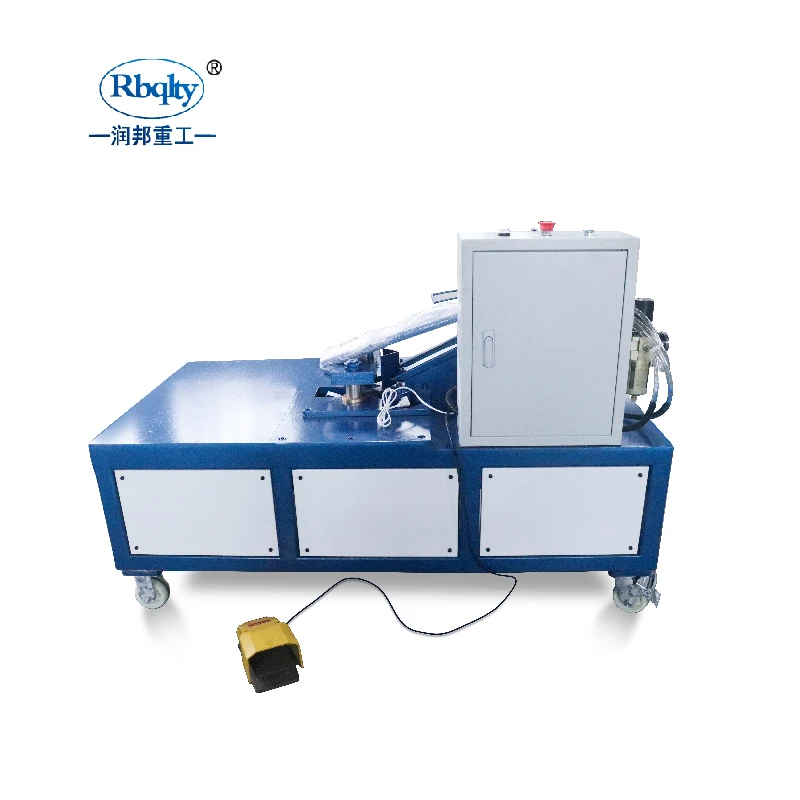

Rbqlty китайская техника HVAC воздуховод TDF угловой код сборочная машина

- Категория: >>>

- Поставщик: Anhui Runbang Heavy Industry Machinery Co. Ltd .

Сохранить в закладки 1601272079722:

Описание и отзывы

Характеристики

Model | Sheet thickness(mm) | Fluid pressure(Mpa) | Weight(kg) | Dimensions(L*W*H) |

PC-12 | 1.2 | 0.6-0.8 | 450 | 1500*800*1050mm |

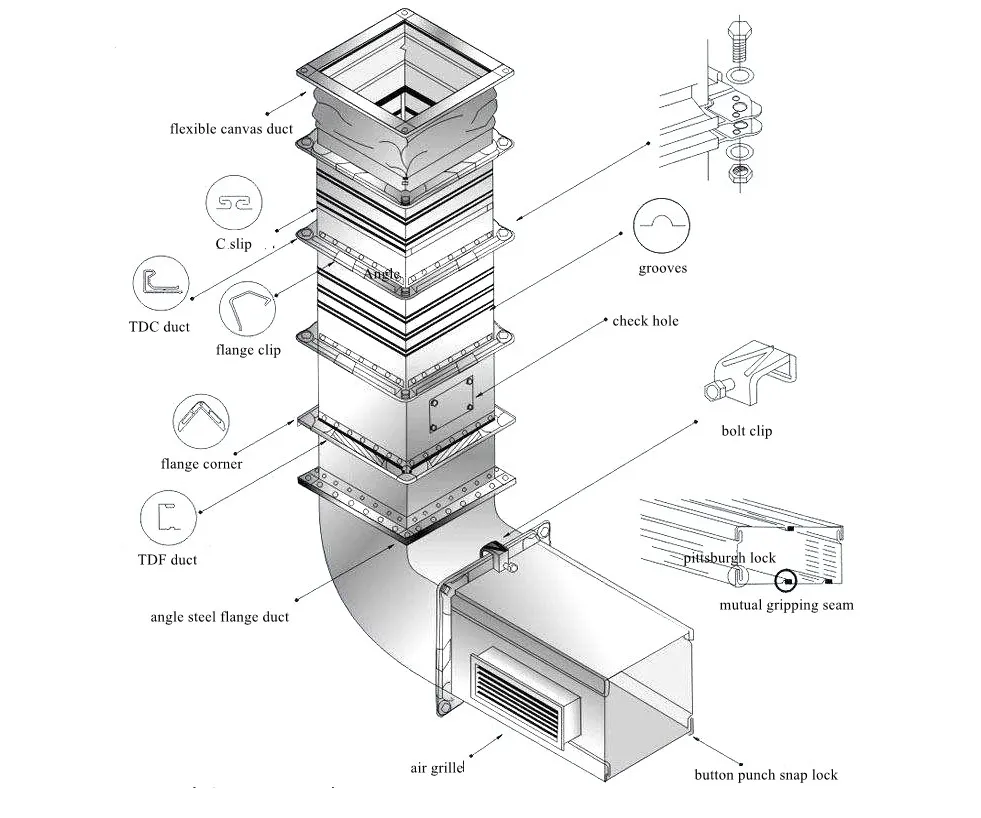

Heating Ventilation Air Conditioning Duct Machine HVAC duct making machine

Simple duct production line

Angle steel flange line | lock forming machine | duct folding machine | duct beading machine |

Angle steel flange making line | pittsburgh lock, hem, C cleat, elbow | fold duct and other sheet metal | leveling and beading 5 or 7 beads |

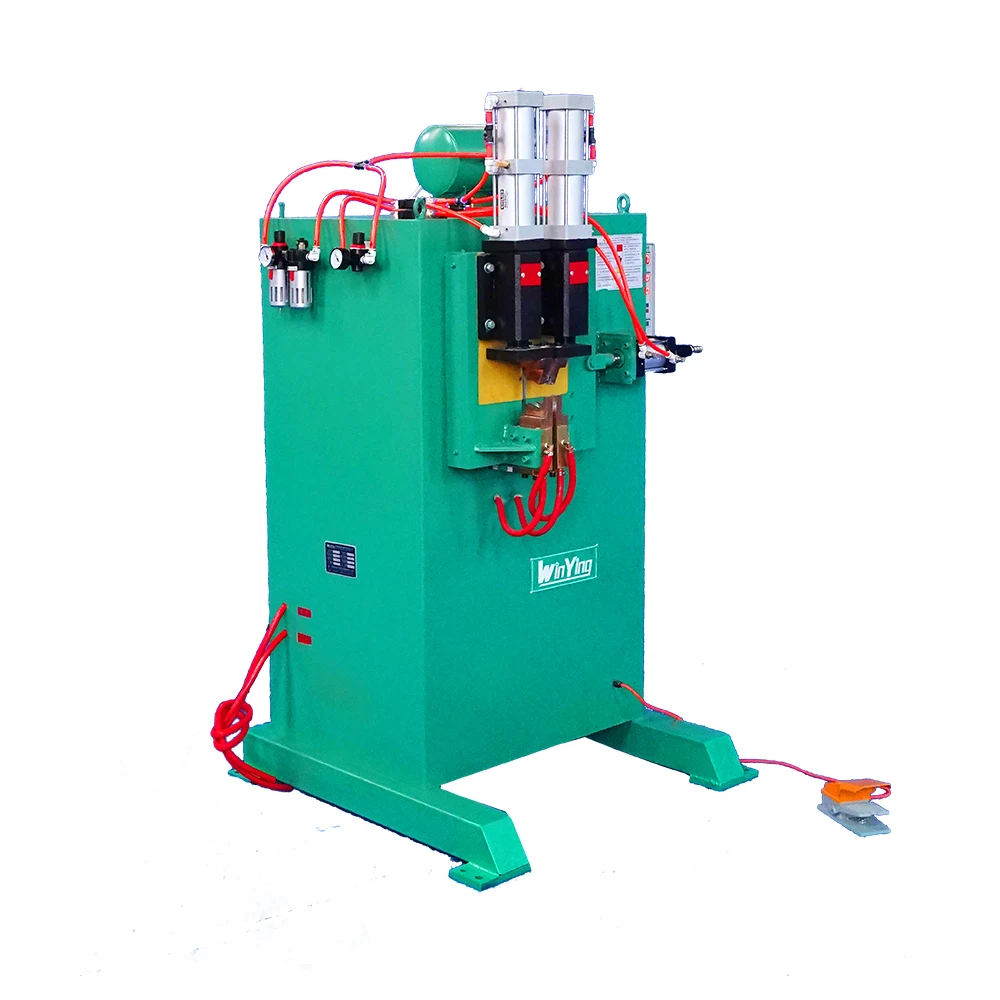

Hydraulic riveter | lock seaming machine | duct shearing machine | duct plasma cutter |

angle steel flange riveting | seam the duct | cut the duct sheet | cut irregular shape duct |

TDF making machine | corner installing machine | corner punching machine | duct notching machine |

transverse flange duct | duct corner fast installing | duct corner fast punching | duct flange notching |

Duct rolling machine | rotary shearing machine | Snap Lock former | S & C lock former |

elbow part | 1.2mm duct sheet | snap lock | S and C cleat |

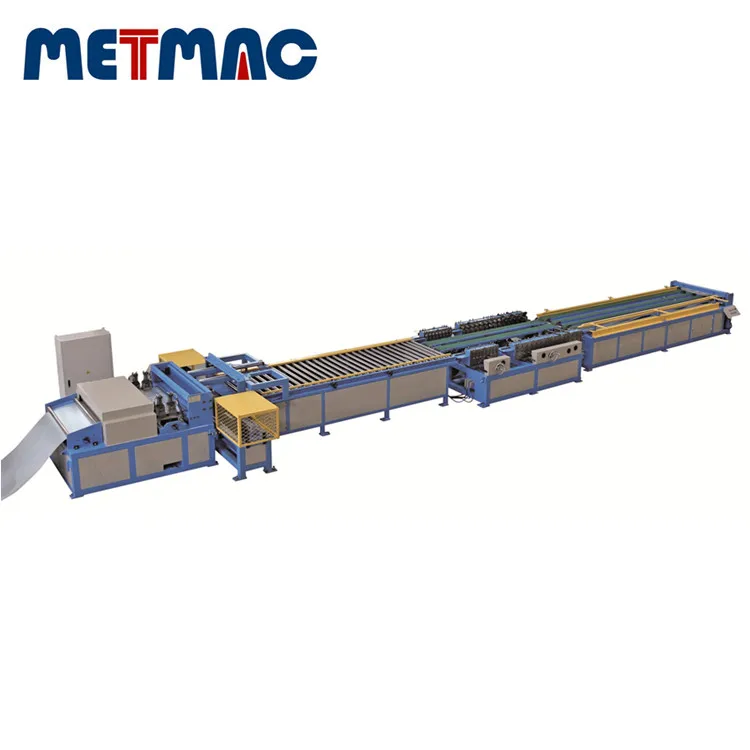

AUTO DUCT LINE 2

SIZE 4800*2160*1450 mm

1.Electric feeding rack 1 set 2 coil cradles(2620*1850*1450mm)

2.Leveling ,beading equipment 1 set

3.Hydraulic fixed angle notching machine (4 sets molds)

4.Hydraulic plate shearing device

5.A CNC controller, software

AUTO DUCT LINE 3

SIZE 5000*2160*1450 mm

1.Electric feeding rack 1 set 2 coil cradles(2620*1850*1450mm)

2.Leveling ,beading equipment 1 set

3.Hydraulic fixed angle notching machine (4 sets molds)

4.Hydraulic plate shearing device,

5.Hydraulic bending device

6.A CNC controller, software

AUTO DUCT LINE 4

SIZE: 18800*3500*1500

1. Electric feeding racks 2 sets 4 coil cradles

2. Leveling ,beading,notching, cutting equipment 1 set

3. High speed lock former device

4. Transferring platform

5. A duplex TDF flange forming machine (Optional a duplex angle steel flange forming machine)

6. A CNC controller, software

AUTO DUCT LINE 5

2. Leveling, beading, notching, cutting equipment 1 set

3. High speed lock former device

4. An electric feeding platform

5. A duplex TDF flange forming machine (Optional a duplex angle steel flange forming machine)

6. A servo feeding platform

7. A bending device

8. A CNC controller, software

9. An electrical cabinet.

U shape auto duct line 5

SIZE 14000*5000*1500 mm

1. Electric feeding racks 2 sets 4 coil cradles

2. One host (line 2 host)

3. Two stainless steel roller convey platforms

4. One fixed joint locking machine

5. One duplex TDF flange forming machine

6. One duplex angle steel flange forming machine

7. One servo feeding platform

8. One hydraulic folding machine

9. One set of computer controlling system

irrevocable L/C at sight

A:Please tell us the following information in detail:

- Material of plate:

-Max thickness:

-Max plate width:

-If possible: you can specify the model;

Q:Where is your factory? How can I get there?

A:You can fly to NanJing LuKou airport directly, we will pick you up in the airport. All our customers, both inland and abroad,

warmly welcome to visit us!

Q:How do you ensure quality in the factory?

A:Quality culture.:We always attach great importance to quality control from the beginning to the end. Our factory has obtained

ISO, CE certification.

Q:How can I pay?

A:You can pay by T/T, Western Union, MoneyGram, Paypal; 30% deposit; pay off the 70% balance before shipment.

Q: How long to produce?

A: Delivery time:15-35 days.

Похожие товары

Производство круглых трубопроводов фланцев электрический угловой Железный фланцевый гибочный станок для продажи

Станок для формовки фланцев круглого воздуховода

Воздуховод металлический лист фланец делая машину T12 дуплекс Фланцевая формовочная машина

AML-1250MM прямоугольная линия машины для формования воздуховодов

ТДФ воздуховод, вентиляционное соединение воздуховода, соплакированная Фланцевая формовочная машина

Сварочный аппарат с угловым фланцем

AML-1550mm Rectangular air duct automatic making machine

Новые поступления

Новинки товаров от производителей по оптовым ценам