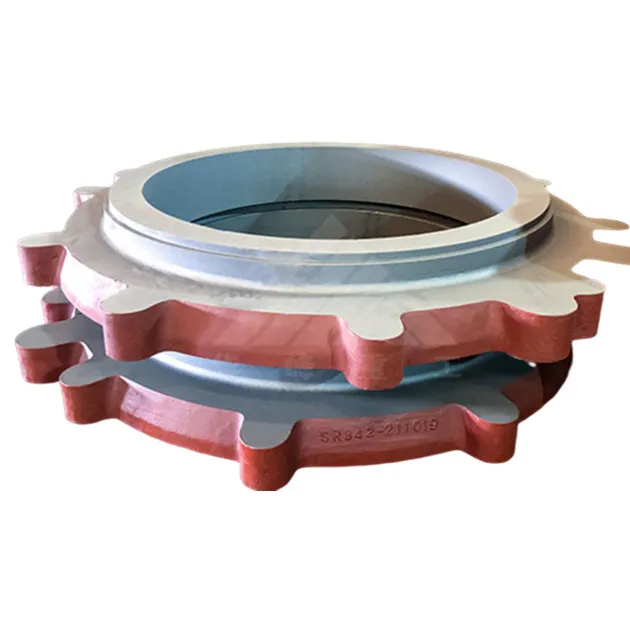

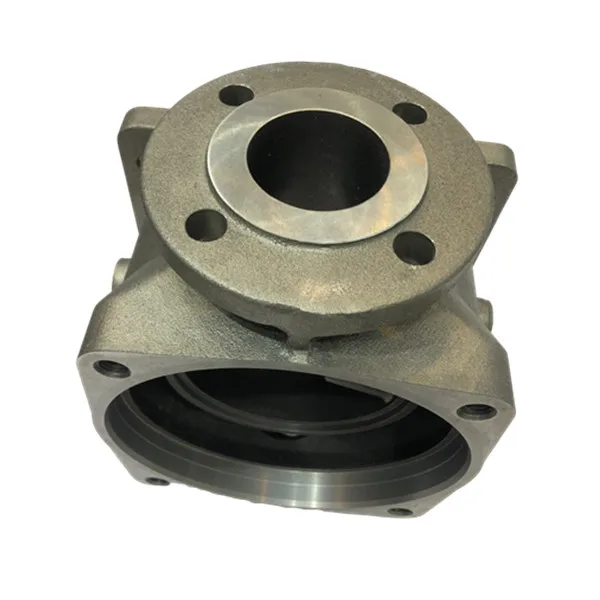

Маховик 100 кг 50 чугунная зеленая отливка вакуумная литая деталь

- Категория: >>>

- Поставщик: Tianjin HYRH Machinery Co. Limited

Сохранить в закладки 1601273271085:

Описание и отзывы

Характеристики

Flywheel 100kg 50kg cast iron green sandcasting vacuum cast part

Properties of gray cast iron

1) The performance of gray cast iron mainly depends on the performance of the matrix and the quantity, shape, size and distribution of graphite. Among them, gray cast iron composed of fine-grained pearlite matrix and flake graphite has the best performance and the widest application range.

2) The tensile strength and plasticity of gray cast iron are much higher than that of steel with the same matrix, but graphite flakes have little effect on the compressive strength of gray cast iron, so gray cast iron is widely used as parts that bear compressive loads, such as machine seats and bearings. Seat etc.

3) Gray cast iron has good casting performance and cutting performance, and the presence of graphite can reduce wear and shock.

Properties of Ductile iron Casting

The main components of ductile iron

Compared with gray cast iron, the main features are high C, high Si, and low S.

Microstructure of nodular cast iron

Matrix + spherical graphite. There are four types of substrates: F, P, F+P, and B.

Schematic diagram of the structure of ductile iron, as shown in Figure 2:

Production method of nodular cast iron

It is obtained by spheroidizing and inoculating molten iron.

The properties of ductile iron

Spherical graphite has the least effect on the splitting of the matrix, so it has high strength, good toughness, plasticity and machinability.

Tianjin HYRH is a company that specializes in Iron steel Aluminum casting area. Founded in 2015, the company has 168 employees, including 28 technical engineers and 30 inspectors.

The company has two automatic sand mold casting line and a shell mold casting production line. We has 2 electric furnaces of 5 tons, 4 electric furnaces of 3 tons and 2 electric furnaces of 1.5 tons.

We has an independent mold workshop, wire-cutting, edm, CNC machining center, mold testing platform and other equipment, can develop and produce molds.

The company has CNC lathes, CNC machining centers (four and five axis), and a variety of auxiliary equipment, a total of more than 30 sets, can be for turning, milling, grinding, drilling, tapping and other processing.

Our testing equipment includes: coordinate detector (3 sets), spectrum detector (2 sets), X-ray defectoscope (3 sets), secondary projector, tension tester, salt spray tester, etc.

The company mainly produces nodular cast iron, gray cast iron and cast steel products, the products involve automobile, aerospace, train, agricultural machinery, furniture, household, communication, sports equipment, kitchenware, pump valve and other industries.

HYRH looks forward to working with you.

Q1: Are you manufacturer?

A1: Yes, we are a factory, specializing in die casting part, iron casting part, forging

parts, stamping parts, sheet metal fabrication, plastic injection parts and aluminum extrusion service.

Q2: Do you accept customized orders?

A2: Yes, we have a design team, OEM and ODM orders are highly welcome.

Q3: What’s your capabilities?

A3: Casting Service, Aluminum Extrusion Service, Sheet Metal Fabrication Service, CNC Machining Service, Surface Finishing Service

(Anodizing & Powder Coating), Plastic Injection Service, etc.

Q4: How to get a quote?

A4: Send us email with your 2D/3D drawing form, quantity, and surface treatment, we will make the quotation ASAP.

Q5: How about quality of products?

A5: We strictly control every detail of the products. Each product is inspected before leaving factory.

Q6: Can you accept mould making?

A6: Yes, we can provide you the mould development & processing.

Похожие товары

Высококачественный индивидуальный дизайн чертежа Литые детали услуги чугунный шкив маховик

Производитель Oem изготовленные на заказ чугунные маховики

Сертификат ISO9001 индивидуальный OEM чугунный маховик

Инвестиционный литой по индивидуальному заказу из нержавеющей стали выпускной коллектор

Изготовленный на заказ cnc подвергая механической обработке алюминиевый Прецизионный литой автоматический Код Сканирующий держатель крышка камеры монитор Автомобильные детали для прохода автомобиля

Оптовая продажа хорошее качество литье из алюминиевого сплава инвестиционное

Изготовленная на заказ литая часть литейного производства OEM магниевого сплава для инвестиций потерянный воск продукт

Новые поступления

Новинки товаров от производителей по оптовым ценам