Высококачественная передовая доска гипса делая оборудование для продажи

- Категория: >>>

- Поставщик: Henan Dafu Mechanical Import And Export Co. Ltd.

Сохранить в закладки 1601273351402:

Описание и отзывы

Характеристики

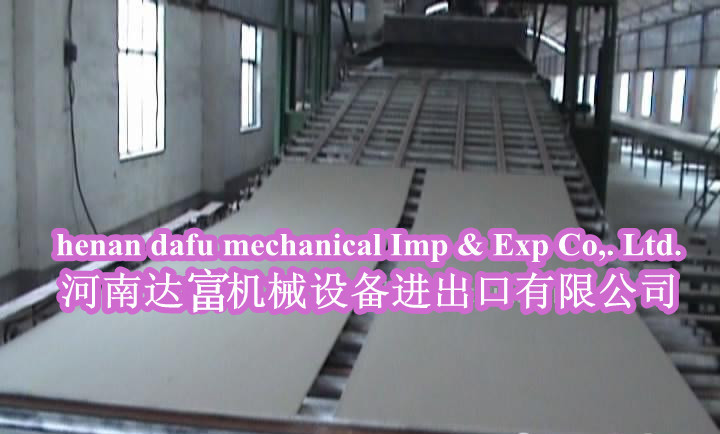

High quality advanced gypsum board making equipment for sale

The gypsum board process is as follows:

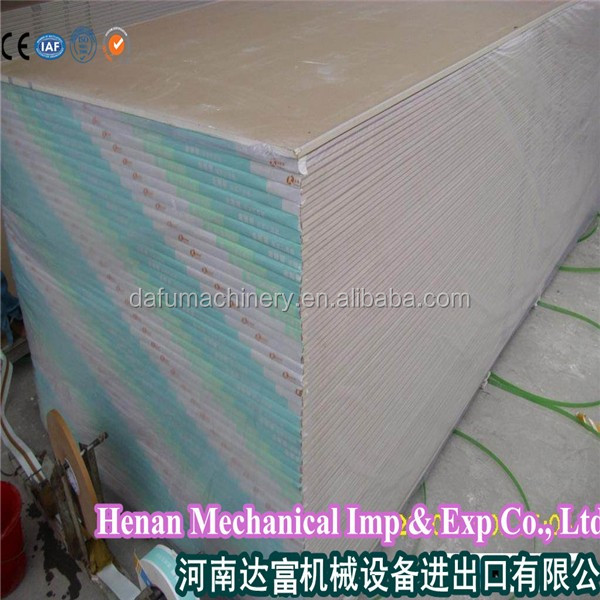

The gypsum board process is as following: Preparation: Modified starch, retarder, and water are mixed in a certain proportion; foaming agent and water are calculated. Gypsum powder is transported to the hopper. All the raw materials are calculated to send to the mixer and make them suitable for use. Belt conveyor: the upper-paper and lower paper will enter into the shaping machine, then the slurry in the mixer will fall on the lower paper of the platform. The required gypsum boards are formed through the shaping machine and then finish the solidification on the freezing belt. After the sized-cutter, it cuts to the needed

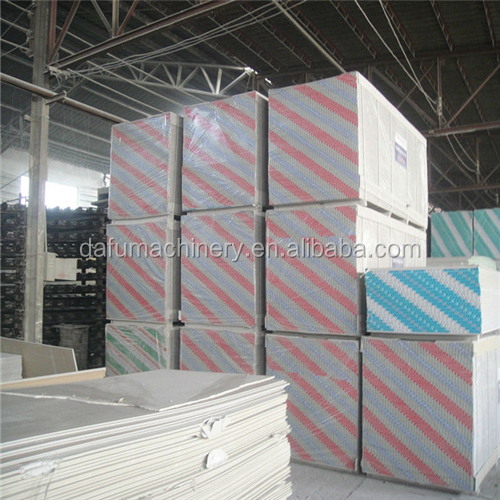

length, then enter the drying kiln through the distributor. Board-exit: After drying, the gypsum board is cut to sized-length. After packing, sealing and stacking, use the forklift to transport it to the warehouse. All the processes are finished.

Main Specifications

Length | 1800,2100,2400,2700,3000,3300,3600 |

Width | 900,1200 |

Thickness | 9.5,12.0,15.0,18.0,21.0,25.0,12.7,15.9 |

Note:According to user requirements, can produce other specifications of the plate | |

Fuel: Coal, natural gas, heavy oil and diesel oil etc.

Main materials:

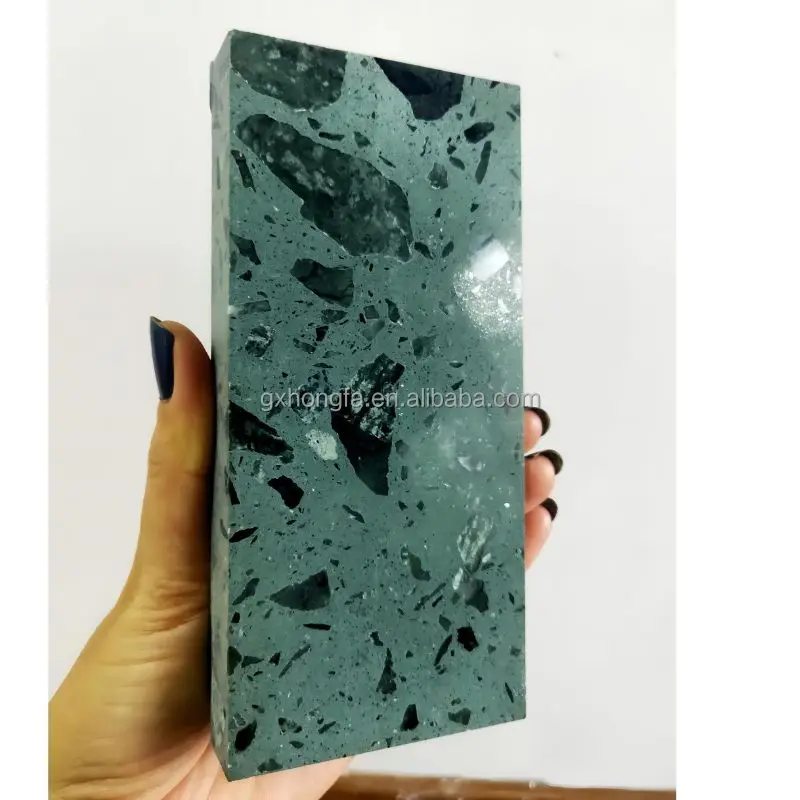

Construction gypsum powder, modified starch, protective paper, foaming agent, water, white latex. Fiberglass and paper pulp (adding selectively)

Production process mainly includes the following several aspects

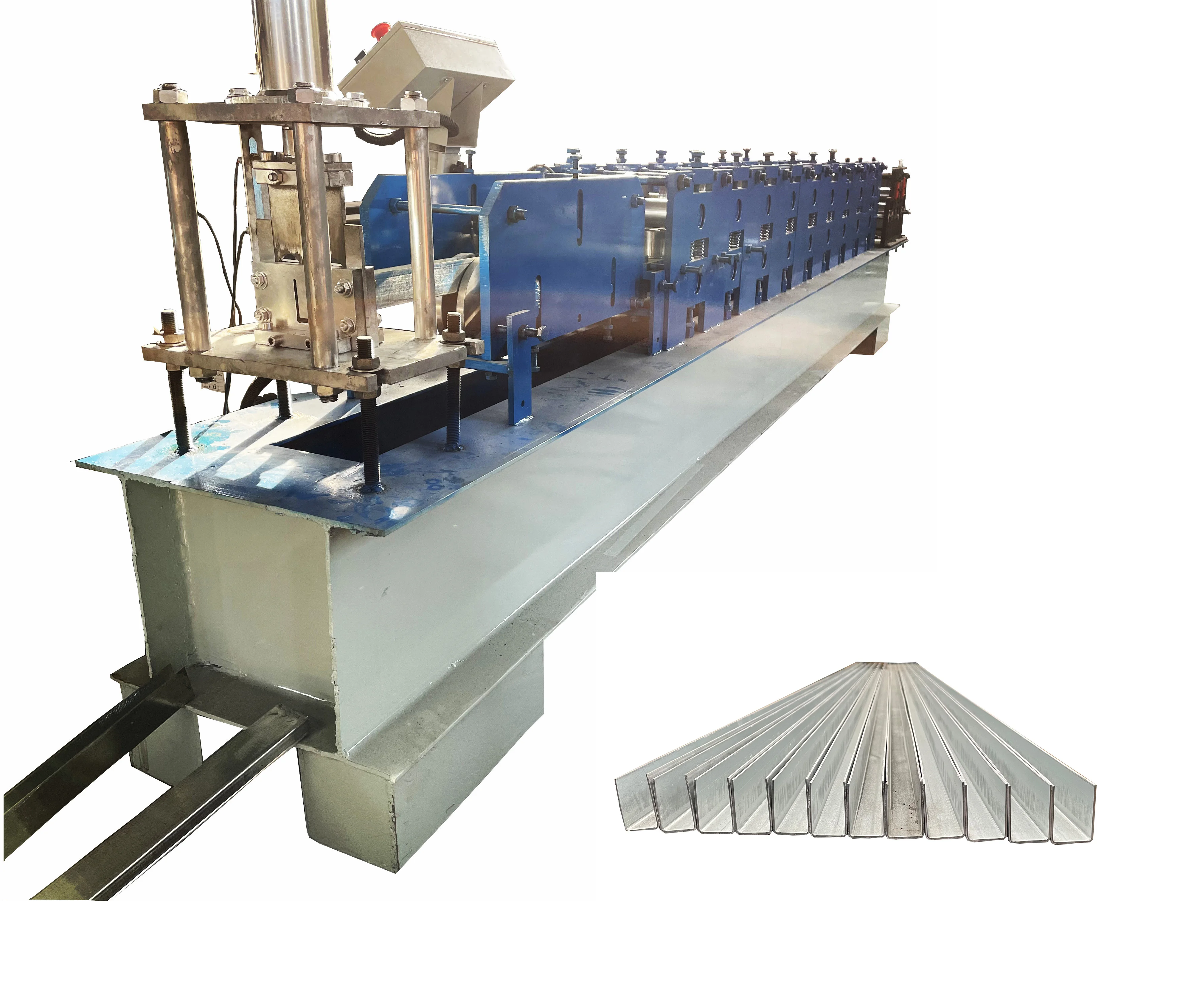

paper supply system, water supply system, starch supply system, vesical supply system, forming section, transportation system, transferring system, heat supply system, drying system board releasing system, dust collecting system, electricity -control system

Application

In the domestic market, the gypsum board is often used in the Ceiling decoration. It is also a very good light walling material. In foreign countries, it is often used as walling material more than the ceiling.

Paper faced gypsum board production line is a kind of light weight board decoration material with many specifications.whose main raw mater are calcined gypsum(natural gypsum,desulfurized gypsum,phosphor gypsum)and card board(face paper),adding certain percentage of water,starch,additives and foaming agent,after mixing,forming,cutting,drying,shearing and sealing procedures etc.It got the features as:light weight,fire-proof,heat insulation,vibration-proof,heat insulation,vibration-proof,simple to produce,easy of application,elegant decoration effect etc.

Pre-sales Service

1.Offering comprehensive technical and business consultation services;

2.Proposing the most suitable scheme and equipment for our clients;

3.Designing and fabricating targeted products according to the special requirements of clients;

Service on Sale

1.Providing initiative and enthusiastic service;

2.Introducing & Demonstrating products and its application to clients;

3.Helping clients to choose equipment.

After-sales Service

1.Highly inspecting equipment in every working procedure, quality comes first;

2.Fast & Safe Delivery;

3.One-year warranty

4. Assisting our clients for foundation construction of equipment;

5.Dispatching engineers to install and debug equipment;

Why choose Henan Dafu Machinery?

high quality

The products have won many awards of varied levels and passed the attestation of ISO Quality Control System SGS of Sweden. Our clients spread all over the country. Products are sold to South Korea, Taiwan, Indonesia, Vietnam, Portugal, Germany and Middle East with the Annual export quantum composing one third of the total sales, wining praises from the purchasers.

If I don't satisfied with price on this site?

The price in the website is a reference, the last price we offered is decided by the production you need. please contact withe us, so we can see if we can make it reasonable.

Meanwhile, do you have a well known about our product? If not,you can not judge fairly about our machines whether cheap or expensive.You care about price because you want to have profit. Know more about our product and marketing strategies, or take a visit of our factory, you will know well about price.

Installation:

1 offer our help knowledgeable engineers online

2 engineer can go abroad to help installation ( the buyer should offer abroad fees and salary )

Henan Dafu Mechanical Import and Export Co. Ltd. , located in Zhengzhou,Henan province, is specialized in manufacturing with more than 20 years’ development and running experience. With high career-honoring spirit and good servicing attitude by all staffs,our company won praise and recognition in the market. We supply quality products and services to customers at home and abroad by good reputation and excellent technology.

If you want to learn more about our production and company ,please contact with me !

//dafumachinery.en.alibaba.com/

Похожие товары

Лидер продаж 2021 стальной роликовый затвор для ворот гаража боковая направляющая профильный станок цена

EPS блок формовочная машина пенопластовая панель производственная линия изоляционная стена производство полистирол

HONGFA Eps панель изоляции Строительная бетонная стеновая машина

ПВХ оконный профиль порог Экструзионная линия WPC дверная доска рама Vinil сайдинг настенная машина для продажи

Машина для производства бетонных плит за рубежом услуги инженера лестницы полностью автоматическая линия по производству плитки терраццо

Высокоэффективные волоконно-армированные пластиковые решетчатые машины

Производственная линия Kaiqian для производства пластиковых стеновых панелей WPC с онлайн-ламинатором

Новые поступления

Новинки товаров от производителей по оптовым ценам