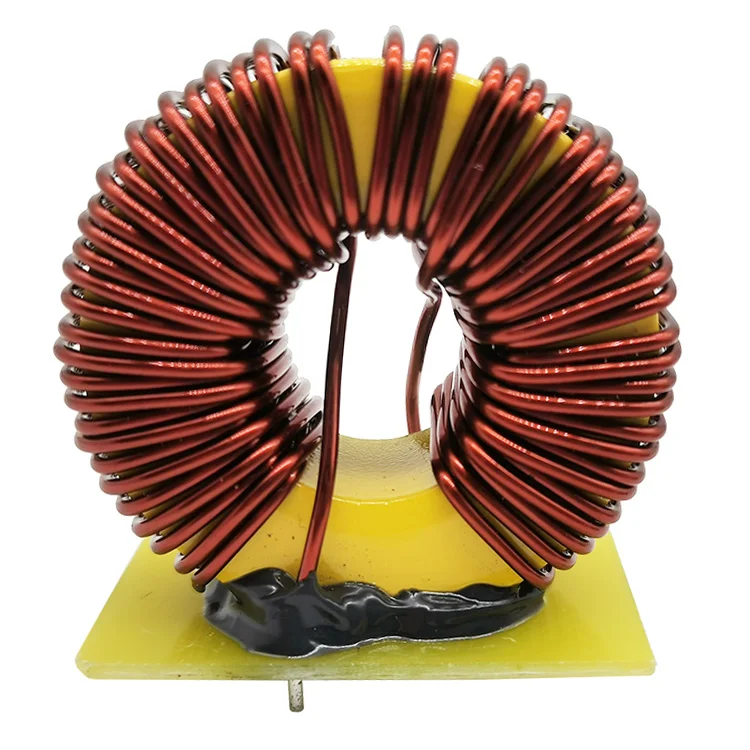

157125 магнитные кольцевые сердечники Sendust 150uH индукторы с медной катушкой высокотоковый SPWM фильтр тороидальные PFC

- Категория: >>>

- Поставщик: Dongguan Guangyu Electronics Co. Ltd

Сохранить в закладки 1601273404374:

Описание и отзывы

Характеристики

PRODUCT SPECIFICATIONS

No | Item | Data | ||||

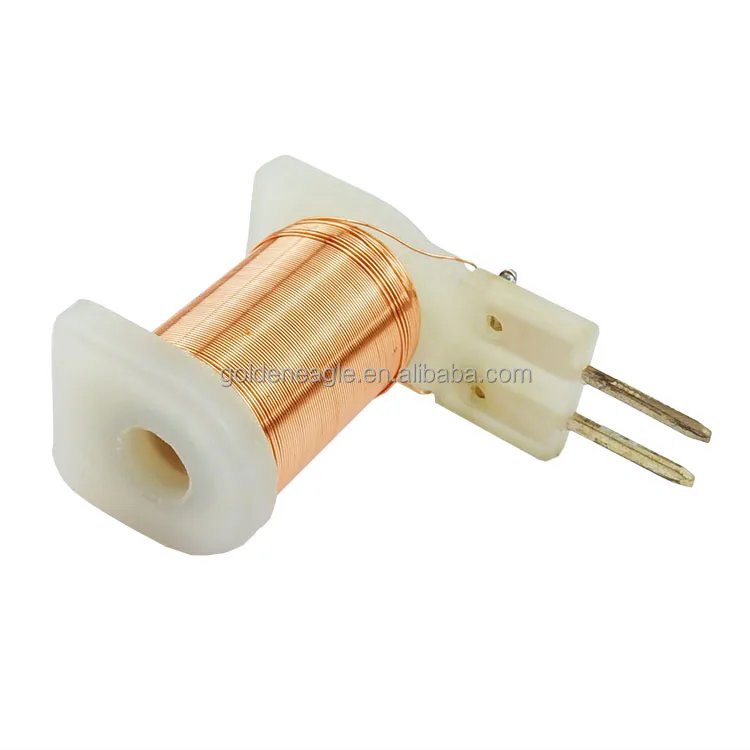

1 | coil | copper | ||||

2 | core | sendust | ||||

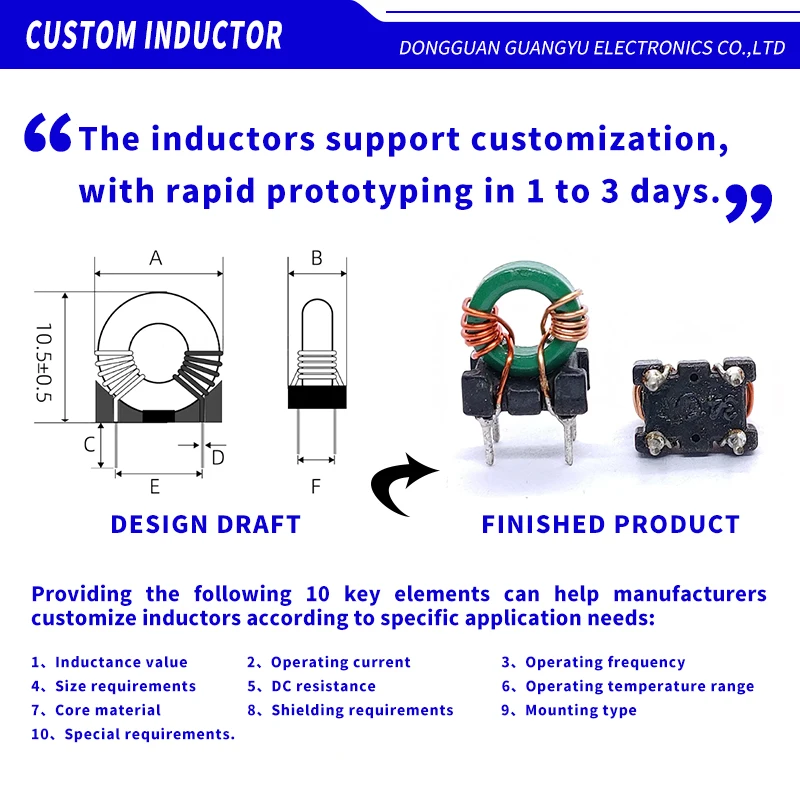

3 | inductor | custom | ||||

4 | Enclosure | NO | ||||

5 | Leads or pads | custom | ||||

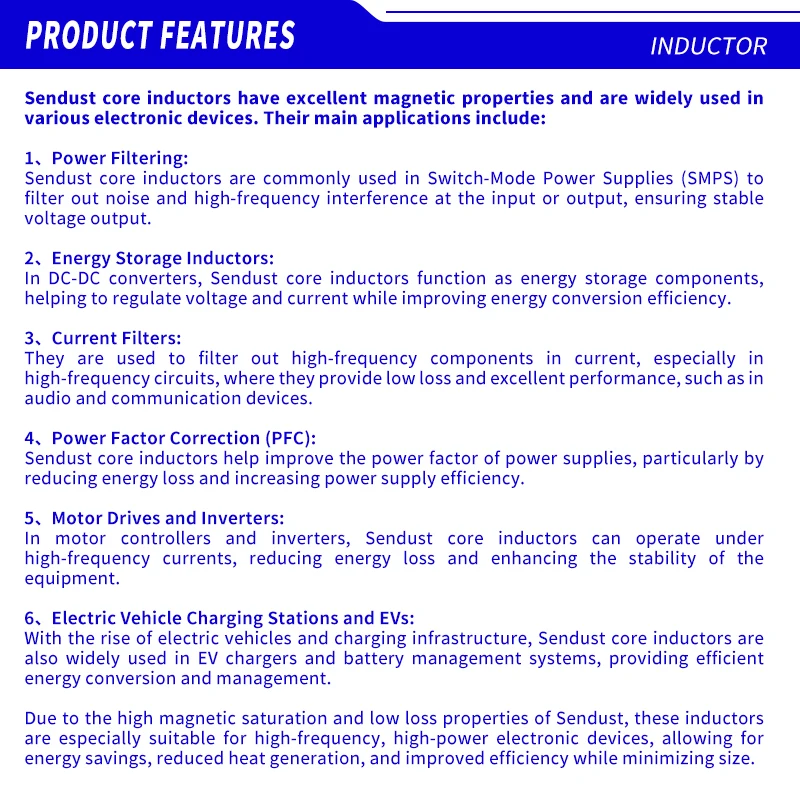

Product Overview

Iron powder inductors

Iron powder cores are a common magnetic core material used in inductors, power filters, transformers, and other applications. Iron powder cores are made by mixing fine iron particles with insulating material. They have the following characteristics:

Characteristics

1. Wide Frequency Range: Iron powder cores are typically suitable for a wide frequency range, especially in the low to mid-frequency range (tens of kHz to several MHz). They are commonly used in energy storage inductors in switching power supplies and inductor elements in power converters.

2. Low Permeability: Iron powder cores have relatively low permeability, usually ranging from 10 to 100. This allows them to operate under higher currents without saturating easily, making them suitable for high-current applications.

3. High Saturation Flux Density: Iron powder cores have a high saturation flux density (B_sat), which allows them to perform well in high-power applications.

4. Low Loss: Although iron powder cores have higher losses compared to ferrite cores, they exhibit relatively low losses in low-frequency applications. However, as the frequency increases, the losses in iron powder cores also increase.

Color Coding

Iron powder cores are often color-coded to indicate different permeability, material composition, and frequency ranges. Common color codes for iron powder cores include:

Yellow/White: Represents a core with permeability of 26, commonly used in power filter inductors.

Red: Represents permeability of 52, suitable for a broad range of applications.

Green/Blue: Represents permeability of 125, used in high-frequency, low-power applications.

Gray: Represents permeability of 75.

These color codes help engineers quickly distinguish between different types of iron powder cores and select the right material for specific circuit designs and operating conditions.

Applications

In summary, iron powder cores are ideal for high-power, high-frequency inductor applications due to their excellent frequency response and strong current-handling capability.

Characteristics

1. Wide Frequency Range: Iron powder cores are typically suitable for a wide frequency range, especially in the low to mid-frequency range (tens of kHz to several MHz). They are commonly used in energy storage inductors in switching power supplies and inductor elements in power converters.

2. Low Permeability: Iron powder cores have relatively low permeability, usually ranging from 10 to 100. This allows them to operate under higher currents without saturating easily, making them suitable for high-current applications.

3. High Saturation Flux Density: Iron powder cores have a high saturation flux density (B_sat), which allows them to perform well in high-power applications.

4. Low Loss: Although iron powder cores have higher losses compared to ferrite cores, they exhibit relatively low losses in low-frequency applications. However, as the frequency increases, the losses in iron powder cores also increase.

Color Coding

Iron powder cores are often color-coded to indicate different permeability, material composition, and frequency ranges. Common color codes for iron powder cores include:

Yellow/White: Represents a core with permeability of 26, commonly used in power filter inductors.

Red: Represents permeability of 52, suitable for a broad range of applications.

Green/Blue: Represents permeability of 125, used in high-frequency, low-power applications.

Gray: Represents permeability of 75.

These color codes help engineers quickly distinguish between different types of iron powder cores and select the right material for specific circuit designs and operating conditions.

Applications

Power Filters: In switching power supply circuits, iron powder cores are commonly used in input filters, output filters, and energy storage inductors, providing high-efficiency energy conversion.

Chokes: In EMI filtering and noise suppression applications, iron powder cores can suppress high-frequency noise due to their high saturation flux density.

Transformers: Iron powder cores play an important role in energy transfer and conversion in isolation transformers or high-frequency transformers.

Chokes: In EMI filtering and noise suppression applications, iron powder cores can suppress high-frequency noise due to their high saturation flux density.

Transformers: Iron powder cores play an important role in energy transfer and conversion in isolation transformers or high-frequency transformers.

In summary, iron powder cores are ideal for high-power, high-frequency inductor applications due to their excellent frequency response and strong current-handling capability.

Why Choose Us

Our Advantages

Transportation

FAQ

Q:What is MOQ? A:Our MOQ is 100pcs. Q:What is the best price?

Q:What is your simple term?

A:Our price based on many aspects,such as labor,materials,processing,machine and so on. And we can quote according to qty you order. Such for 100pcs,1000pcs,10000pcs.

Q:What is your simple term?

A:Normally,we need to charge the sample and freight when we first cooperation.

Q:Where to use?

A:Our product can be widely applied in many industries. Such as Communication, Security, Power supply, Digital, Lighting, and Home appliances.

Q:Where do you sell?

A:We have more than 15 years of experience in this field with different certificates,CE, RoHS,

SGS, ISO9001. Our product mainly sells to Europe and Asia.

SGS, ISO9001. Our product mainly sells to Europe and Asia.

Похожие товары

Пользовательские 157125 33uH Sendust сердечники индукторы медная катушка SPWM инвертор PFC тороидальные Индукторы

228,98 ₽ - 232,22 ₽

Китай, высокое качество, катушка катушки, медная проволока, воздушный сердечник, катушка индуктора для переключателя

100 МЧ тороидальная силовая индукционная катушка 1uH тороидальная дроссельная катушка индуктор тороидный индуктор кольцевой сердечник 430uH

Пользовательские 157125 2.5mH Sendust магнитное кольцо Sendust сердечники индукторы медная катушка хранения энергии тороидальные Индукторы

454,71 ₽ - 459,03 ₽

Индивидуальный класс индуктивности D цифровой фильтр питания экранированный высокомощный индуктор цифровой аудио усилитель мощности индуктор

Индивидуальные звуковые устройства, электрическая катушка индуктивности, медная катушка индуктивности для привода звуковой катушки

Настраиваемый индуктор с плоской медной катушкой

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $