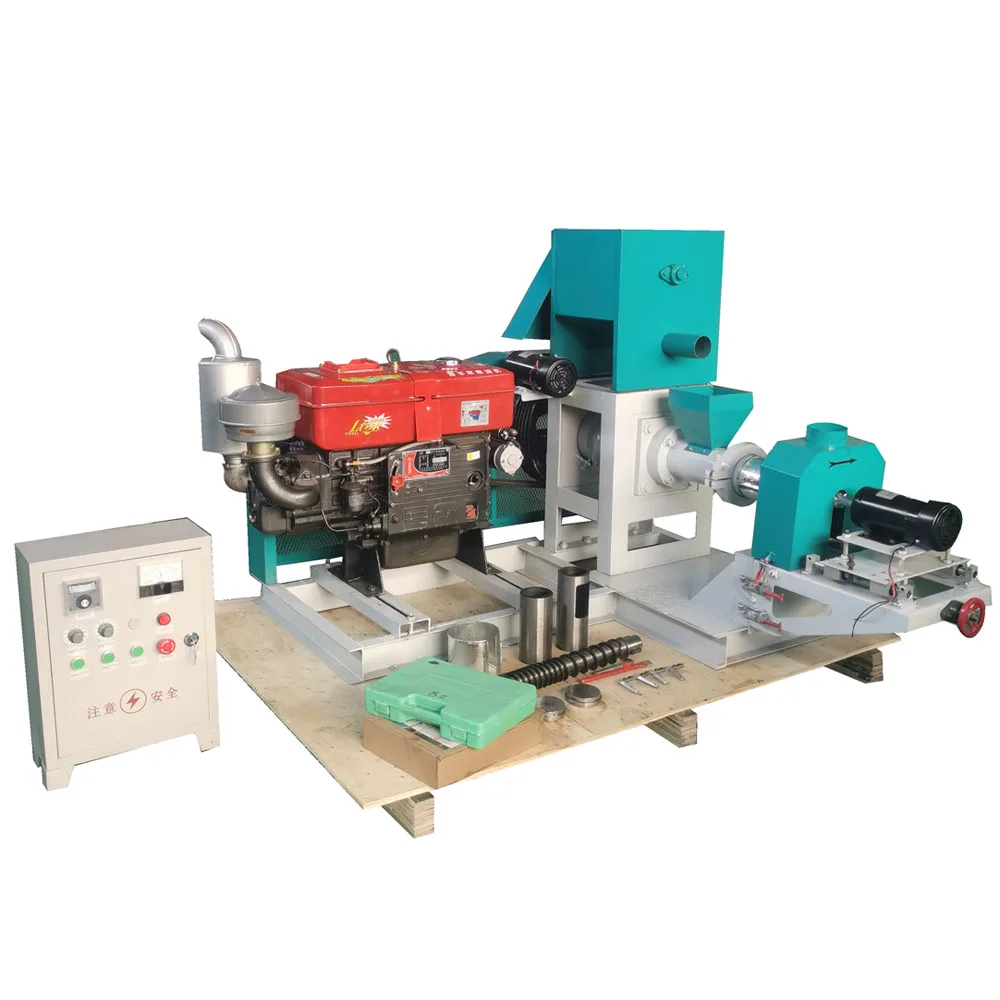

Коммерческая Высококачественная машина для производства кормовых гранул экструдер корма рыбы по заводской цене

- Категория: >>>

- Поставщик: Lerford Machine LLC

Сохранить в закладки 1601274321122:

Описание и отзывы

Характеристики

Fish Feed Machine: An Overview

As the world's population continues to grow, the demand for food, including fish, also increases. With this, there is a need for efficient and economical fish feed production. Fish feed machines have become essential equipment for fish farmers and industries to produce high-quality and nutritious fish feed. In this article, we will discuss the working principle of fish feed machines, the application of fishing pellet making machines, the advantages of fish feed pellets, the raw materials needed to make fish feed, and the difference between our company's machines and others. Additionally, we will highlight how we guarantee the quality of our machines and the after-sales service in our factory.

Working Principle of Fish Feed Pellet Machine

Fish feed pellet machines are designed to produce high-quality pellets for fish feed. The machines work by utilizing a die and roller that are the main components that compress raw materials into pellets. First, the raw materials are fed into the hopper, then passed through a screw feeder that transports the raw materials to the conditioner. In the conditioner, steam and water are added to soften the mixture, making it easier to form a pellet. The softened mixture is then passed through the die and roller, where pressure is applied to shape the mixture into pellets. The machine's compact size makes it easy to install, operate, and maintain.

Application of Fishing Pellet Making Machine

Fish feed pellet machines are used widely by fish farmers, feed mills, and aquaculture feed processing industries globally. The main purpose of the machine is to produce high-quality pellets that meet the nutritional requirement of fish. The pellets are uniquely designed to float on the water, making it easier for fish to detect and consume them. Additionally, the machine's flexibility allows it to produce pellets of varying sizes, shapes, and flavors, depending on the type of fish and the intended application.

Advantages of Fish Feed Pellet

There are numerous benefits of using fish feed pellets, including:

1. Enhanced Nutritional Value: Fish feed pellets are formulated to contain a balanced diet that meets the nutritional requirements of fish. The pellets are made from a variety of ingredients that provide essential nutrients such as proteins, vitamins, and minerals that improve fish growth, and health.

2. Improved Feed Efficiency: Fish feed pellets are compact, dense, and easily digestible, ensuring that fish consume more and utilize the available nutrients efficiently. Additionally, the pellets float on the water, making it easier for fish to consume them.

3. Cost-effective: Pelletizing fish feed reduces wastage and improves cost-effectiveness. Unlike traditional fish feed, pellets are easy to handle, store, and distribute.

4. Easy to Store and Transport: Fish feed pellets have a longer shelf-life, reducing the chances of spoilage and wastage. Additionally, the pellets are compact, making them easy to transport and store.

Technical Date of Floating Fish Feed Pellet Making Machine:

Model | WSJY-40 | WSJY- 50 | WSJY-60 | WSJY-70 | WSJY-80 | WSJY-90 | WSJY-120 |

Capacity --- kg/h | 30-40 | 60-80 | 120-150 | 180-250 | 300-350 | 400-450 | 500-700 |

Pelleting Diameter--- mm | 1-8 | 1—8 | 1 —10 | 1-10 | 1 —10 | 1 —10 | 1-10 |

Motor Power--- kw | 5 | 7.5 | 15 | 18.5 | 22 | 37 | 55 |

Cutting Power--- w | 400 | 400 | 400 | 400 | 1100 | 1500 | 2200 |

Screw Rod Diameter-- mm | 40 | 50 | 60 | 70 | 80 | 90 | 120 |

Cooking degree | >95% | >95% | >95% | >95% | >95% | >95% | >95% |

Size(m) | 1.4*1.03*1.1 | 1.45*1.08*1.25 | 1.46*1.14*1.25 | 1.6*1.4*1.35 | 1.6*1.4*1.35 | 2.1*1.45*1.35 | 2.1*1.45*1.35 |

Weight(kg) | 260 | 350 | 355 | 580 | 700 | 950 | 1700 |

What Raw Materials Are Needed to Make Fish Feed?

To produce high-quality fish feed pellets, different raw materials are needed, including:

1. Fish Meal: Fish meal is a common ingredient in fish feed pellets. It is high in protein and contains essential amino acids that are beneficial to fish growth and health.

2. Soybean Meal: Soybean meal is another key ingredient in fish feed pellets. It's a good source of protein and contains a wide range of essential amino acids.

3. Corn Gluten Meal: This ingredient is a byproduct of corn milling, and it's rich in protein. Its inclusion in fish feed pellets improves the feed's protein content.

4. Wheat Flour: Wheat flour is a good source of energy and essential minerals and vitamins that are necessary for fish growth and development.

What's the Difference Between Our Company's Machines and Others?

Various factors distinguish our fish feed machines from others, including:

1. Quality Construction: Our machines are made from high-quality materials that ensure durability and longevity. Additionally, our machines adhere to international standards, including ISO and CE guidelines.

2. Customizability: Our fish feed machines are highly customizable, allowing customers to select the size, shape, and color of pellets they need.

3. Efficiency: We offer machines that are designed to be efficient, cost-effective, and easy to use, ensuring that our customers get the best value for their money.

How Do We Guarantee the Quality of Our Machines?

At our factory, we have established rigorous quality control measures to ensure that our products meet international standards. Our experienced engineers and technicians work closely to ensure that all our machines are tested, calibrated, and inspected before they are released into the market. Additionally, we use high-quality materials to construct our machines, ensuring that they are durable and reliable. We also offer customers a one-year warranty period on all our machines.

What is the After-sales Service in Our Factory?

We offer exceptional after-sales service for our customers, including:

1. Technical support: We have a team of experienced technicians who provide technical support and troubleshooting services to our customers.

2. Spare parts availability: We maintain a stock of spare parts for all our machines, ensuring that we can offer timely replacements when needed.

3. Training: We provide comprehensive training on how to operate and maintain our machines to ensure that customers can get the best results.

What Are the Advantages of Our Factory?

Our factory is a leader in the production of fish feed machines, with the following advantages:

1. Quality Control: We have established rigorous quality control measures to ensure that our machines meet international standards.

2. Customization: We offer highly customizable machines that cater to every customer's specific requirements, ensuring that they get the best value for their money.

3. Efficiency: We design machines that are efficient, cost-effective, and easy to operate, ensuring that customers get the best results.

4. After-sales service: We provide exceptional after-sales service to our customers, including technical support, spare part availability, and training.

Conclusion

Fish feed machines are essential equipment for fish farmers, feed mills, and aquaculture feed processing industries. The machines' efficiency, cost-effectiveness, and ability to produce high-quality fish feed pellets have contributed to their widespread use. At our factory, we pride ourselves on producing quality machines that are durable, reliable, and offer customers value for their money. Additionally, we provide exceptional after-sales service to our customers, ensuring that they get the best results.

Похожие товары

Мини-гранулятор Tolcat

Зернистая кукурузная молотковая мельница, лезвия, измельчитель, оптовая цена

Бензиновый двигатель, электрический силос для домашнего использования, корм для животных, прямая продажа, сельскохозяйственный корм для животных, мини-машина для резки соломы

Автоматическая Высокоэффективная пластиковая машина для гранулирования переработанного пластика, экструзионная машина для гранулирования

Плоская форма для кормления кур

SSHJ двухвальный питающий смеситель для смешивания кормовых материалов, пеллетный смеситель, лопастная мешалка

Оборудование для производства кормов для животных

Новые поступления

Новинки товаров от производителей по оптовым ценам