Цена на блочные машины популярный бизнес зарабатывает деньги дома получает за работу в режиме онлайн оборудование для производства кирпича 2023

- Категория: >>>

- Поставщик: Linyi Dongyue Imp. & Exp. Co. Ltd.

Сохранить в закладки 1601274744639:

Описание и отзывы

Характеристики

Product Description

Product Application

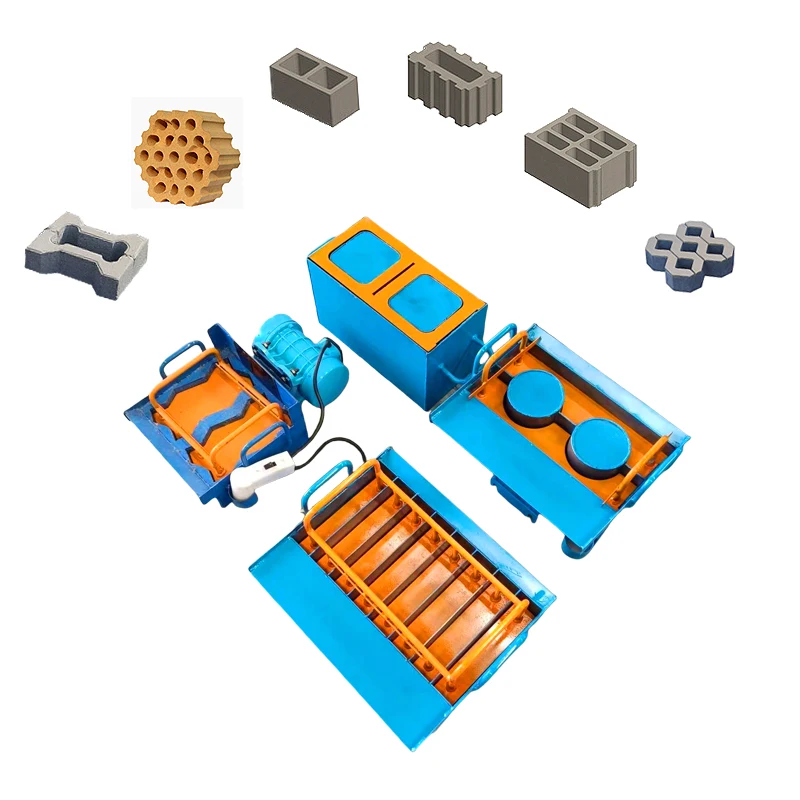

1.QT10-15 Brick Production Line is fully automatic brick making machine, which can make different sizes of hollow blocks, solid bricks, paver and curbstone by changing moulds.

2. QT10-15 Brick Making Machine adopt to hydraulic pressure moulding system , so the brick machine has more stable and higher-efficiency working status and the bricks produced are of better quality, larger density and higher strength.

1.QT10-15 Brick Production Line is fully automatic brick making machine, which can make different sizes of hollow blocks, solid bricks, paver and curbstone by changing moulds.

2. QT10-15 Brick Making Machine adopt to hydraulic pressure moulding system , so the brick machine has more stable and higher-efficiency working status and the bricks produced are of better quality, larger density and higher strength.

QT10-15 hydraulic concrete block machine AS the molds are changeable, this concrete brick machine is able to produce different types of blocks/bricks, and this is a hydraulic machine can produces a stronger block, due to the greater pound pressure applied by the hydraulic system. The block manufacturer can also realize substantial savings by using less cement. A ratio from 8:1 to 11:1 sand/cement can be achieved. This machine is designed for the manufacturer with a steady year turnover and with a certain

number cash to make the factory running.

number cash to make the factory running.

Packing & Delivery

Specification

item | value |

Applicable Industries | Building Material Shops, Manufacturing Plant, Construction works , Energy & Mining, Other |

Showroom Location | Egypt, India |

Condition | New |

Type | Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Other |

Brick Raw Material | CONCRETE |

Processing | Brick Production Line |

Method | Hydraulic pressure & vibration forming |

Automatic | Yes |

Production Capacity (Pieces/8 hours) | 15360 pcs/8hours, 108000 pcs/8hours, 26880 pcs/8hours, 28800 pcs/8hours |

Place of Origin | China |

Shandong | |

Brand Name | Donyue |

Voltage | 220/380/ Or adapt to lacal voltage |

Dimension(L*W*H) | 3800*2300*3550mm |

Warranty | 1 Year |

Key Selling Points | High efficiency |

Brick size | 400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other |

Machinery Test Report | Provided |

Video outgoing-inspection | Provided |

Marketing Type | Hot Product 2023 |

Warranty of core components | 1 years |

Core Components | PLC, Motor |

Weight (KG) | 11500kg |

Product Name | QT10-15 Automatic Concrete Cement Block Making Machine |

Raw material | Fly Ash Cement Sand Concrete |

Block Type | Hollow Solid Paver Block Curbstone |

Color | According to Customers' Requirements |

Power | 51.2KW |

Material | Q235B High Grade Steel |

Vibrating Force | 90-110kN |

Certification | CE/SGS/ISO9001 |

Pallet size | 1300*900*30mm |

Pcs/mould | 10 Pcs (400*200*200mm ) |

Production Parameter

Main Features

1) The motor for the host machine is Germany SIEMENS brand or ABB brand

2) Control PLC: we select original Japan Mitsubishi PLCcombine with independently develop machine control program, assure stable

and high efficiency working status

3) The switch will use France Schneider brand and Japan Omron

4) Mould: newest heat treatment device and carburizing treatment will assure longer mould life span and ensure the strength of

mould reach to 54-58 HRC so that the mould can be used more than 100 thousand times.

5)Material and welding: all materials and spare parts selected according to international CE standard, Carbon dioxide protection

welding will assure whole line stable running.

2) Control PLC: we select original Japan Mitsubishi PLCcombine with independently develop machine control program, assure stable

and high efficiency working status

3) The switch will use France Schneider brand and Japan Omron

4) Mould: newest heat treatment device and carburizing treatment will assure longer mould life span and ensure the strength of

mould reach to 54-58 HRC so that the mould can be used more than 100 thousand times.

5)Material and welding: all materials and spare parts selected according to international CE standard, Carbon dioxide protection

welding will assure whole line stable running.

FAQ

1. who are we?

We are based in Shandong, China, start from 2010,sell to Africa(15.00%),South Asia(13.00%),Mid East(13.00%),Southeast Asia(13.00%),Domestic Market(10.00%),North America(5.00%),Eastern Europe(5.00%),Eastern Asia(4.00%),South America(4.00%),Oceania(4.00%),Central America(4.00%),Northern Europe(4.00%),Western Europe(3.00%),Southern Europe(3.00%). There are total about 501-1000 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Block Making Machinery (AAC Line; ALC Line; Concrete Block Making Machinery; Clay Brick Making Machine; Pallet); Autoclave; Color Metal Tile Equipment, Color Metal Tile, Forklift

4. why should you buy from us not from other suppliers?

The main products are AAC production line , Wall panel, steam curing sand-lime brick production equipment manufacturing, Burn-free brick machine, equipment manufacturers, stone coated roof tile etc with 9 series and more than 60 type of products

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese,German,Russian

We are based in Shandong, China, start from 2010,sell to Africa(15.00%),South Asia(13.00%),Mid East(13.00%),Southeast Asia(13.00%),Domestic Market(10.00%),North America(5.00%),Eastern Europe(5.00%),Eastern Asia(4.00%),South America(4.00%),Oceania(4.00%),Central America(4.00%),Northern Europe(4.00%),Western Europe(3.00%),Southern Europe(3.00%). There are total about 501-1000 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Block Making Machinery (AAC Line; ALC Line; Concrete Block Making Machinery; Clay Brick Making Machine; Pallet); Autoclave; Color Metal Tile Equipment, Color Metal Tile, Forklift

4. why should you buy from us not from other suppliers?

The main products are AAC production line , Wall panel, steam curing sand-lime brick production equipment manufacturing, Burn-free brick machine, equipment manufacturers, stone coated roof tile etc with 9 series and more than 60 type of products

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese,German,Russian

Company Profile

LINYI Dongyue Exp&Imp Co.,ltd is a Chinese manufacturer of dedicated machinery for construction blocks and panels. Our company offers complete production lines for premium building components such as the autoclaved sand-lime brick, autoclaved aerated concrete block, and autoclaved aerated concrete / autoclaved lightweight concrete panel. Additionally, we provide various types of pressure vessels and block-making machines. By choosing DONGYUE, customers can enjoy professional benefits with our dedicated services for design, installation, layout planning, technology transfer, and production guidance.

Our company was incorporated in 1994 under the former name of DONGYUE Building Material Machinery. We now have a registered capital of 53.5 million RMB and total assets amounting to 380 million RMB. Our current staff roster exceeds 1500 employees. Each year we assemble more than 5000 sets of block-making machines and over 500 autoclaved aerated concrete / autoclaved lightweight concrete panel production lines. The annual production capacity of our AAC block production line ranges between 100 to 400 thousand cubic meters. Similarly, our autoclaved aerated panel equipment can yield up to 300 thousand cubic meters each year.

We are the proprietor of a world-class R&D center. As a hi-tech enterprise of Shandong province, we have been declared as a national technology center and a designated employer of post-doctoral graduates. In recent years, we have collaborated extensively with higher learning institutions such as the universities of Tianjin, Qingdao, Jinan, and Tsinghua. Talent cultivation has always been an integral part of our corporate agenda. In order to instill proficiency into a new generation of specialists our company has hired experts in the fields of mechanical design, automation, and manufacturing.

Regular technological exchange forums are maintained with development partners in countries such as Germany and Japan. This mutually beneficial process has allowed us to introduce state-of-the-art technology and management concepts from foreign sources into our own repertoire. Practical implementation of this knowledge has led to the development of nationally advanced construction machinery such as the hydraulic press and the aerated concrete block cutting machine.

Our core staff consists of 1 honorary fellow of the Chinese Academy of Engineering, 10 senior engineers, 31 senior technicians, and more than 160 R&D specialists. Over 5% of our revenue is invested in technological development each year. We have won successive bids for important national projects such as the Torch Program and New Product Development Program.

Two of our subsidiaries have earned the title of "Shandong Hi-tech Enterprise". We have development centers at both provincial and municipal levels. Over the years we have accumulated 12 utility model patents and 4 national invention patents. In recognition of our many accomplishments, DONGYUE has been presented with numerous honors including the "National Energy Technology Advancement Award", "Shandong Outstanding Energy Conservation Award", "Shandong Technology Advancement 3rd Place Award", and "Linyi City Technology Advancement 2nd Place Award".

Through meticulous management and perseverance, we will exceed all expectations. With quality as our highest priority, we have established an optimized control & regulation system. Support from a large distribution network and world-class customer service have allowed our products to gain momentum in a fiercely competitive market. We have led the competition by passing the certifications of both CE and the ISO9001:2000 Management System.

Together, we will create a brighter tomorrow!

Our company was incorporated in 1994 under the former name of DONGYUE Building Material Machinery. We now have a registered capital of 53.5 million RMB and total assets amounting to 380 million RMB. Our current staff roster exceeds 1500 employees. Each year we assemble more than 5000 sets of block-making machines and over 500 autoclaved aerated concrete / autoclaved lightweight concrete panel production lines. The annual production capacity of our AAC block production line ranges between 100 to 400 thousand cubic meters. Similarly, our autoclaved aerated panel equipment can yield up to 300 thousand cubic meters each year.

We are the proprietor of a world-class R&D center. As a hi-tech enterprise of Shandong province, we have been declared as a national technology center and a designated employer of post-doctoral graduates. In recent years, we have collaborated extensively with higher learning institutions such as the universities of Tianjin, Qingdao, Jinan, and Tsinghua. Talent cultivation has always been an integral part of our corporate agenda. In order to instill proficiency into a new generation of specialists our company has hired experts in the fields of mechanical design, automation, and manufacturing.

Regular technological exchange forums are maintained with development partners in countries such as Germany and Japan. This mutually beneficial process has allowed us to introduce state-of-the-art technology and management concepts from foreign sources into our own repertoire. Practical implementation of this knowledge has led to the development of nationally advanced construction machinery such as the hydraulic press and the aerated concrete block cutting machine.

Our core staff consists of 1 honorary fellow of the Chinese Academy of Engineering, 10 senior engineers, 31 senior technicians, and more than 160 R&D specialists. Over 5% of our revenue is invested in technological development each year. We have won successive bids for important national projects such as the Torch Program and New Product Development Program.

Two of our subsidiaries have earned the title of "Shandong Hi-tech Enterprise". We have development centers at both provincial and municipal levels. Over the years we have accumulated 12 utility model patents and 4 national invention patents. In recognition of our many accomplishments, DONGYUE has been presented with numerous honors including the "National Energy Technology Advancement Award", "Shandong Outstanding Energy Conservation Award", "Shandong Technology Advancement 3rd Place Award", and "Linyi City Technology Advancement 2nd Place Award".

Through meticulous management and perseverance, we will exceed all expectations. With quality as our highest priority, we have established an optimized control & regulation system. Support from a large distribution network and world-class customer service have allowed our products to gain momentum in a fiercely competitive market. We have led the competition by passing the certifications of both CE and the ISO9001:2000 Management System.

Together, we will create a brighter tomorrow!

Materials

Finished products

Our Services

Excellent team, Good service

Pre -sale

1.Update the production schedule in time.

2.Quality supervision.

3.Production acceptance.

4.Shipping on time.

After-Sales

1.Warranty period :1 YEAR after acceptance, during this period we will offer free spare parts if they are broken.

2.Training how to install and use machine.

3.Engineers available to service overseas.

4.Skill support the whole using life.s and bottles in all shapes.

1.Update the production schedule in time.

2.Quality supervision.

3.Production acceptance.

4.Shipping on time.

After-Sales

1.Warranty period :1 YEAR after acceptance, during this period we will offer free spare parts if they are broken.

2.Training how to install and use machine.

3.Engineers available to service overseas.

4.Skill support the whole using life.s and bottles in all shapes.

feedback

Company Introduction

Certifications

Похожие товары

Ручная машина для производства полых блоков QTJ4-45/Оборудование малого бизнеса дома

288 411,50 ₽

Автоматическая машина для производства глиняной почвы, блокировочная машина для производства глиняных блоков на продажу

776 492,50 ₽

Портативная машина для производства кирпича ручная в Папуа Новая Гвинея

Китай портативные большие колеса африканская Qtj4-40 мобильные гидравлические кирпичные брусчатки автоматическая машина для производства цемента с полыми блоками продажи

188 576,75 ₽ - 310 597,00 ₽

Низкая цена небольшая портативная ручная машина для производства цементного кирпича продажи в Кении

54 354,48 ₽ - 55 463,75 ₽

Заводская цена портативная машина для производства кирпича продажи ручная изготовления камень Африканский ключевой блок предприятие HEN Power

22 185,50 ₽ - 66 556,50 ₽

Заводская цена небольшой портативный кирпич делая машину для продажи ручной

43 261,73 ₽ - 46 589,55 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $